Unloading gear capable of realizing engine braking and engine start/stop

A technology of engine braking and unloading device, which is applied in the direction of engine control, machine/engine, electrical control, etc., can solve the problems of long starting time and unstable starting, achieve fast response speed, reduce cylinder pressure and resistance torque, The effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

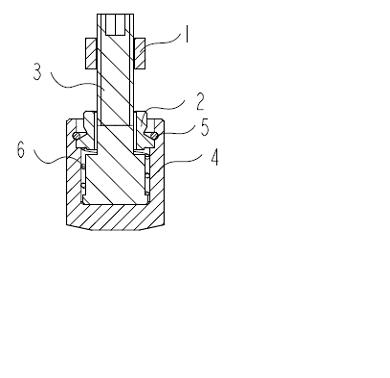

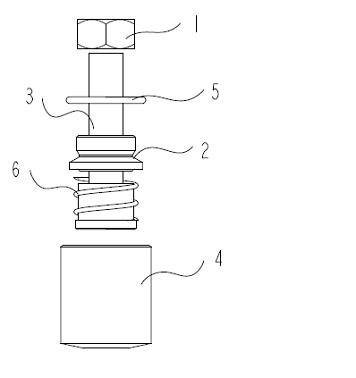

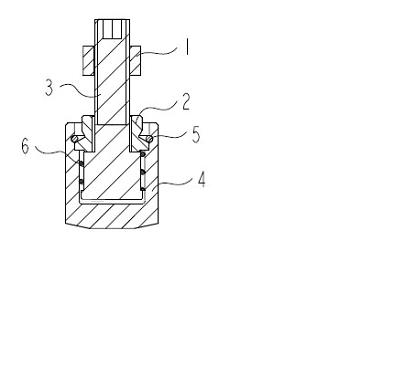

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail; Figure 1-4 As shown, the unloading device for engine braking and engine start and stop can be realized. It is composed of a driven valve mechanism and a control oil circuit mechanism. Bolt 3, valve body 4, circlip 5, and spring 6; lock nut 1 fixes the adjusting bolt 3 on the support frame 11, the bottom of the adjusting bolt 3 is in contact with the bottom of the valve body 4, and the spring 6 is located inside the valve body 4. The spring seat 2 is set on the spring 6 and fixed by the circlip 5; a control oil circuit mechanism is arranged on the oil circuit, and a solenoid valve 7 and a control valve 8 are fixed on the support frame 11 of the control oil circuit mechanism. The control valve 8 is provided with a control valve. Valve circlip 9 and control valve return spring 10.

[0015] Such as figure 1 As shown, under idling co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com