Method and device for laser shock processing of fastening holes

A technology of laser shock strengthening and fastening holes, which is applied in the field of laser shock strengthening of fastening holes and internal surface strengthening of small-diameter fastening holes, which can solve unfavorable continuous operation, small impact force of hole wall, and increased surface roughness of materials and other problems, to achieve the effect of being conducive to continuous operation, improving fatigue life and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

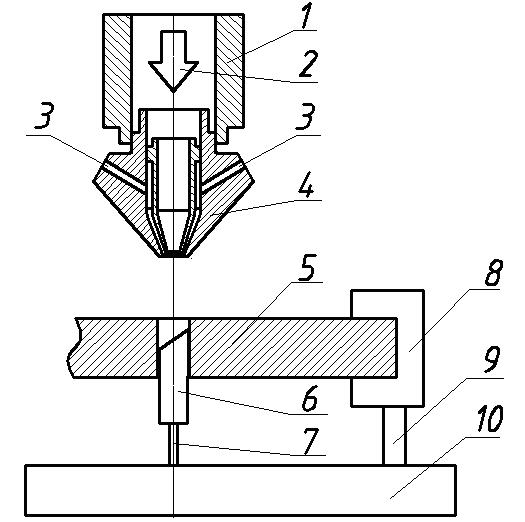

[0019] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the figures.

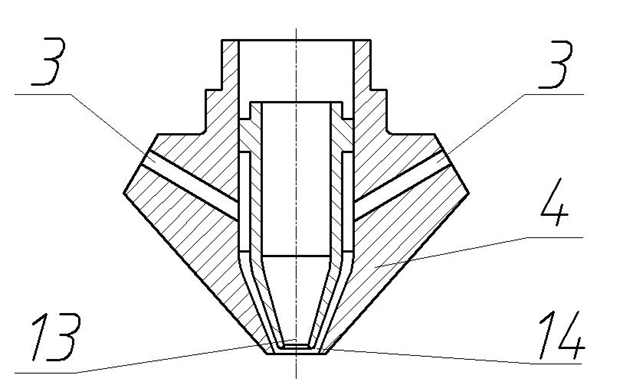

[0020] The laser shock peening device for fastening holes in the present invention includes: laser, focusing system 1, laser head 4, workpiece 5, energy absorbing rod 6, feed mechanism A7, feed mechanism B9, clamp 8, workbench 10, Control System. Wherein the water inlet 3 is connected to the water pipe, and the water flow enters the water inlet 3 and sprays to the fastening hole through the annular water nozzle 14 at the lower end of the laser head 4, so that the water flow can be evenly injected into the small hole. The energy absorbing rod 6 is placed inside the fastening hole, and the energy absorbing rod 6 is clamped on the feed mechanism A7. The feed mechanism B9 realizes the up and down movement of the workpiece 5 through the clamp 8 .

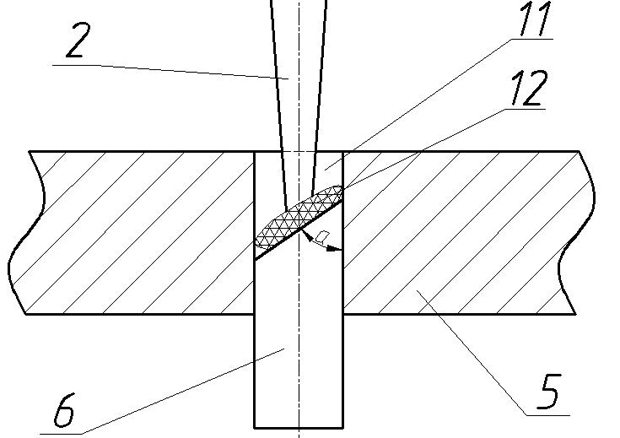

[0021] See the principle of the present invention figure 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com