Water dispersible granule compounded by difenoconazole and propineb

A technology of difenoconazole and dispersible granules, applied in biocides, bactericides, biocides, etc., can solve problems such as increased environmental hazards, decreased drug utilization, and impact on control effects, and achieve environmental relief. Harm, good dispersibility and resuspension, effect of improving control effect and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

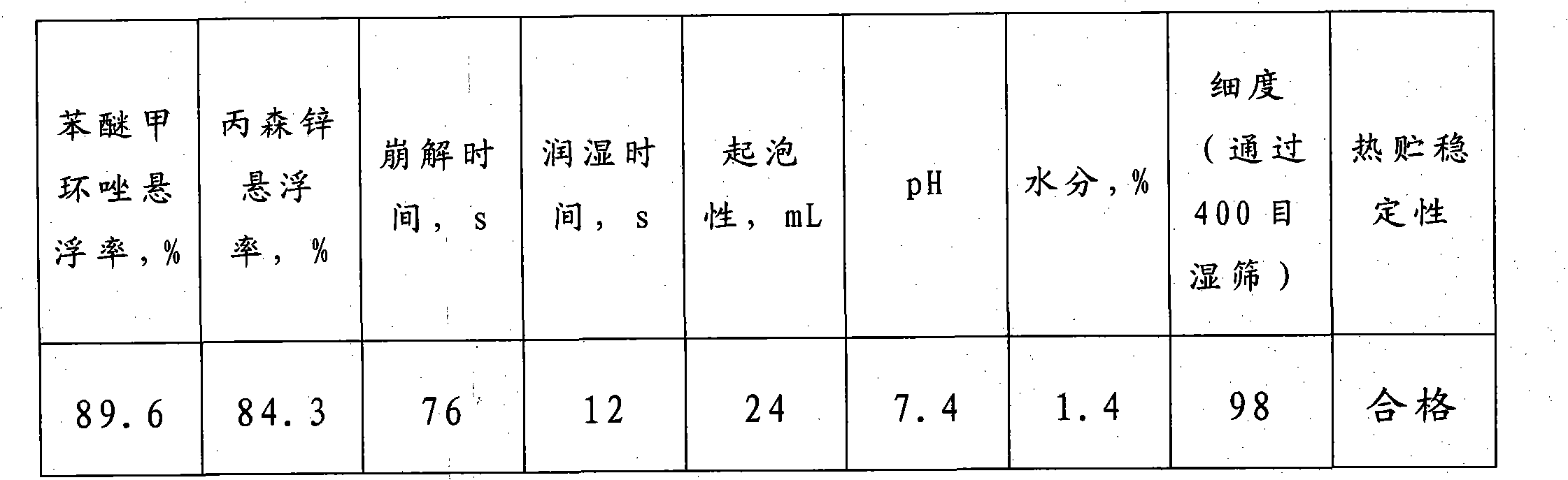

[0016] Difenoconazole original powder 26Kg, Prosenzine original powder 330Kg, dispersant acrylic copolymer sodium salt 30Kg, naphthalenesulfonic acid formaldehyde condensate sodium salt 20Kg, wetting agent alkyl sodium sulfate 25Kg, disintegrant sulfuric acid Ammonium 25Kg, anti-hardening water agent disodium EDTA 15Kg, filler corn starch 20Kg, light calcium 9Kg, put into the cone mixer, mix for 30 minutes, and perform jet pulverization to make the fineness reach 800 mesh; the pulverized material Add water for kneading, the amount of water added is 80Kg, the kneaded material is extruded and granulated, then dried by a fluidized bed dryer, and then sieved to obtain the finished product. The tested product indicators are shown in Table 1:

[0017] Table 1 Product index parameters

[0018]

Embodiment 2

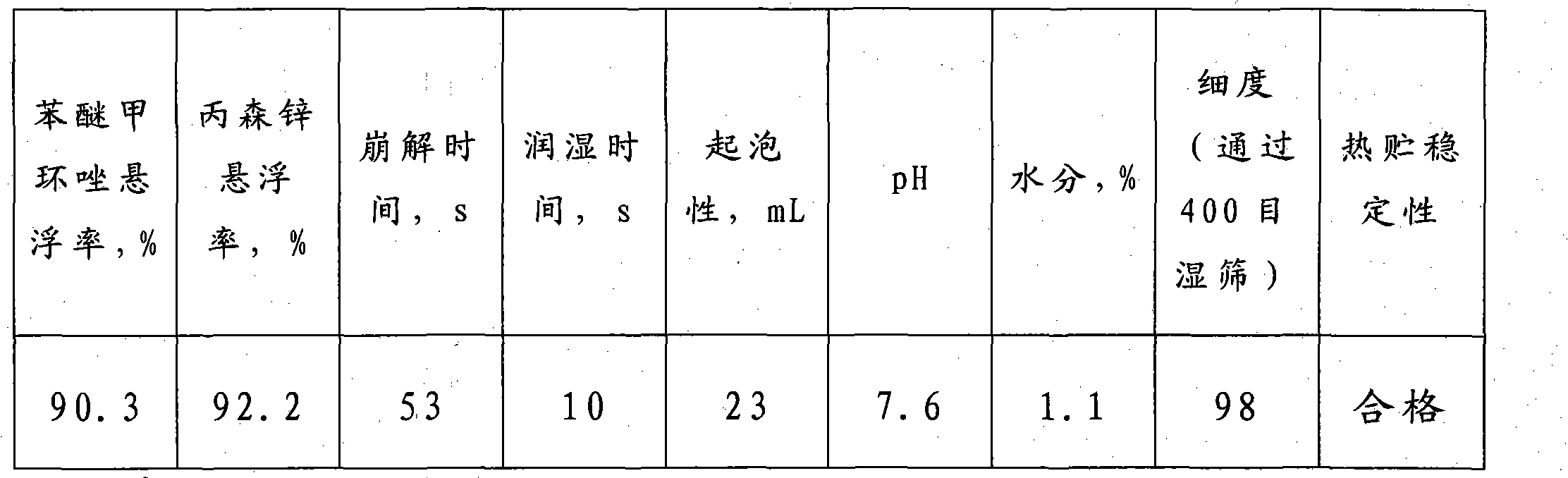

[0020] Difenoconazole original powder 26Kg, Prosenzine original powder 330Kg, dispersant acrylic copolymer sodium salt 30Kg, naphthalenesulfonic acid formaldehyde condensate sodium salt 20Kg, wetting agent alkyl sodium sulfate 25Kg, disintegrant sulfuric acid Ammonium 25Kg, anti-hardening water agent disodium EDTA 15Kg, filler corn starch 20Kg, light calcium 9Kg, put into the cone mixer, mix for 30 minutes, and perform jet pulverization to make the fineness reach 800 mesh; the pulverized material It is added to the boiling granulator for granulation, and the finished product is obtained after screening. The tested product indicators are shown in Table 2:

[0021] Table 2 Product index parameters

[0022]

Embodiment 3

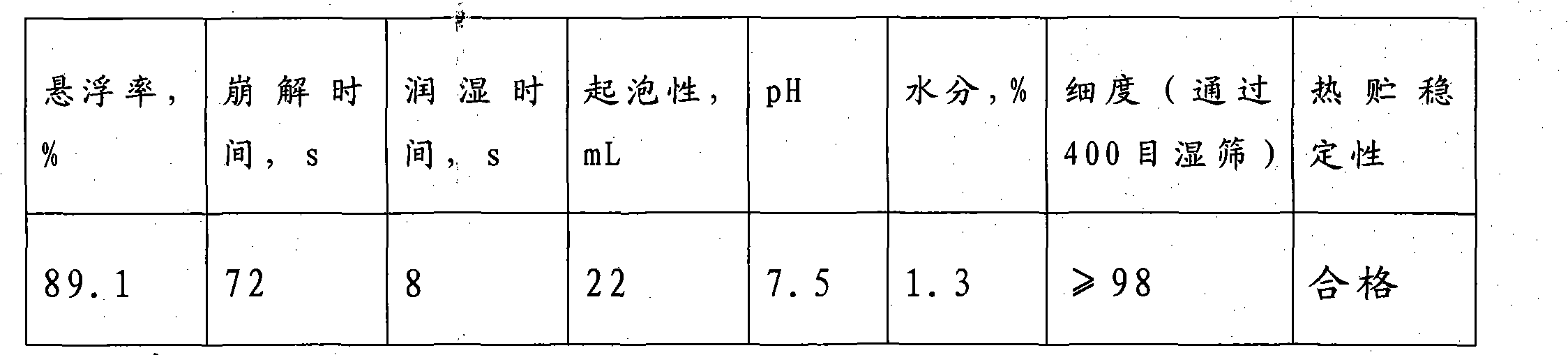

[0024] Difenoconazole raw powder 11Kg, Prosenzine raw powder 62Kg, dispersant polyoxyethylene polyoxypropylene block copolymer 8Kg, wetting agent alkyl aryl polyoxyethylene ether sulfate 3Kg, disintegrating agent sulfuric acid Ammonium 8Kg, anti-hardening agent sodium tripolyphosphate 3Kg, filler corn starch 5Kg, put into the cone mixer, mixed for 30 minutes, airflow pulverization, so that the fineness can reach 800 mesh; the pulverized material is kneaded with water, The amount of water added is 16Kg, the kneaded material is extruded and granulated, then dried by a fluidized bed dryer, and then sieved to obtain the finished product. The tested indicators are shown in Table 3:

[0025] Table 3 Product index parameters

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com