LED packaging structure and packaging method thereof

A technology of LED packaging and packaging method, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of difficult to achieve automatic production, difficult to control packaging quality, loss of light output rate, etc., to achieve controllable quality, low production cost, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

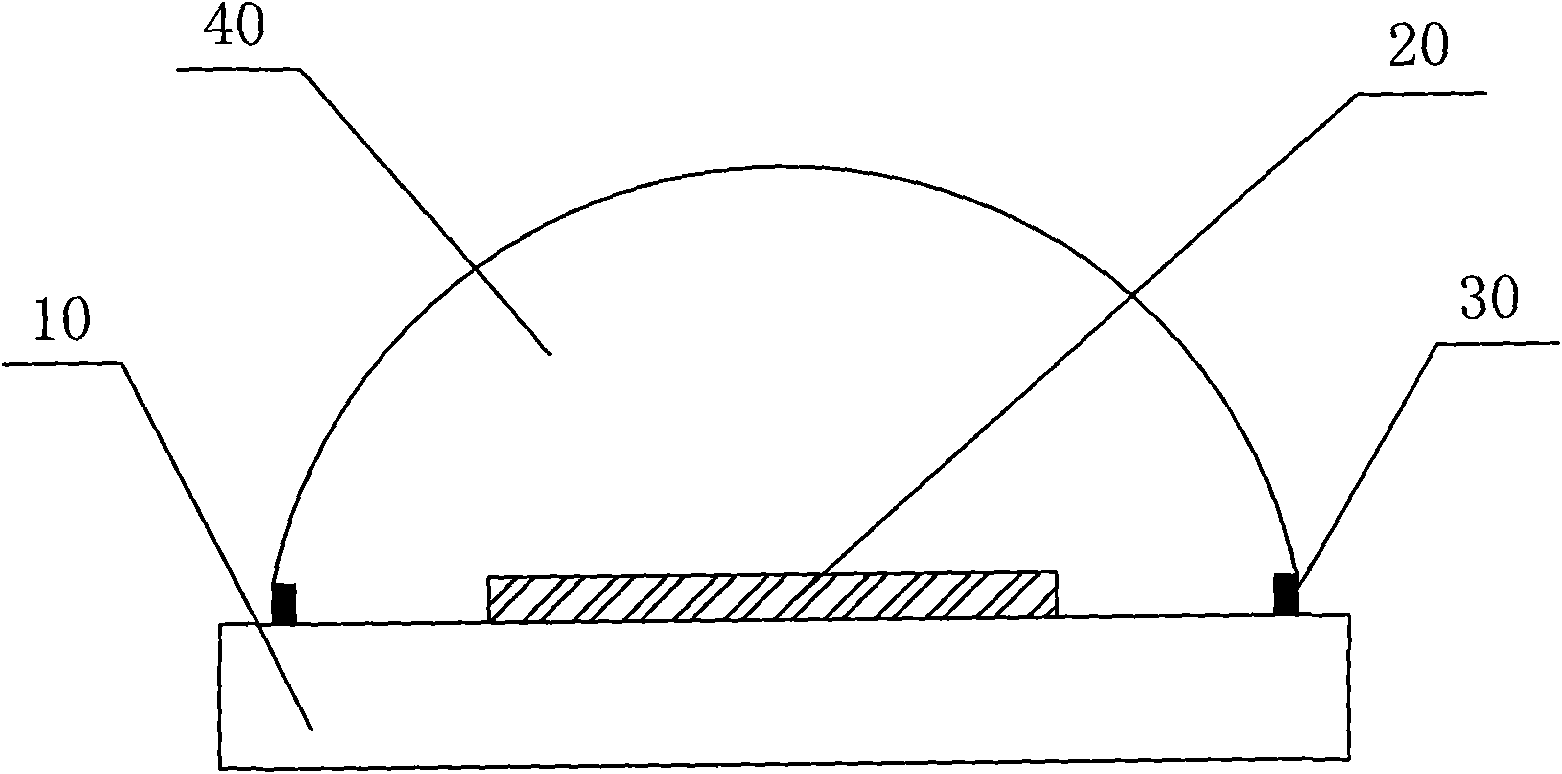

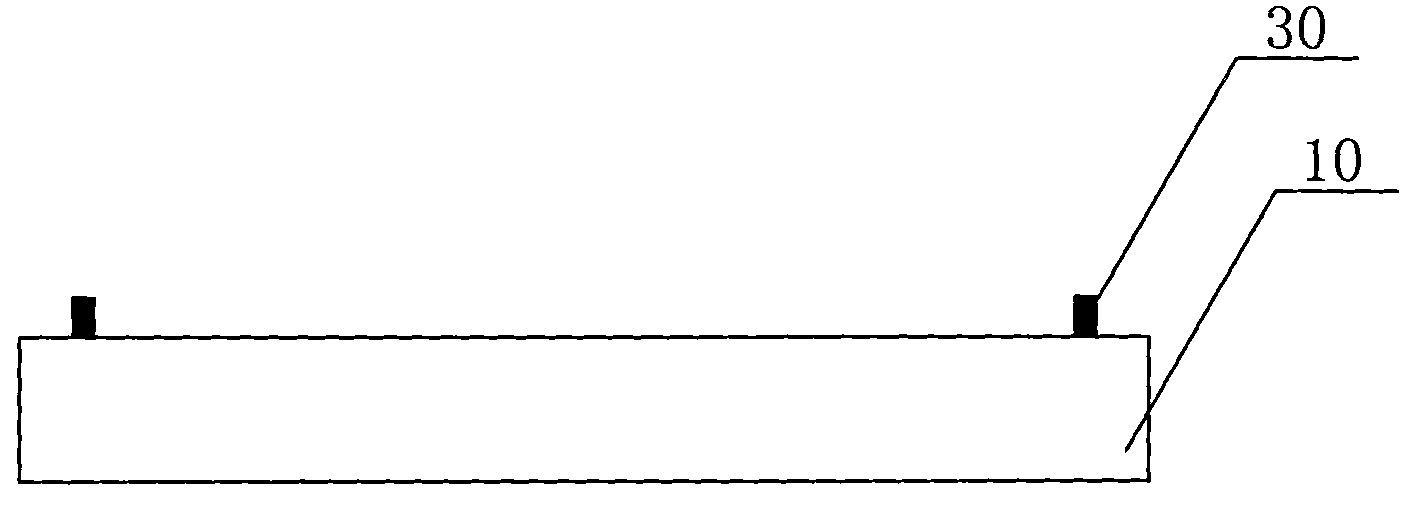

[0025] Please also see figure 1 and figure 2 ,in, figure 1 is a schematic cross-sectional view of the first embodiment of the LED packaging structure of the present invention, figure 2 yes figure 1 Top view of the LED package structure shown. The LED packaging structure includes a substrate 10 , an LED chip 20 , a convex wall 30 and a colloid lens 40 . The raised wall 30 is arranged on the substrate 10 to form a restricted area, and at least one LED chip 20 is arranged in the restricted area of the raised wall 30 and fixed on the substrate 10 . The colloid lens 40 is arranged on the surface of the LED chip 20 and wraps the LED chip 20 inside.

[0026] Specifically, the substrate 10 may be a silicon wafer, a ceramic wafer, a printed circuit board (PCB), a metal-based printed circuit board (MCPCB), or a glass wafer.

[0027] The width of the convex wall 30 is 10um-5000um, and the height is 5um-5000um. The convex wall 30 can be circular arc ring, or polygonal ring, or ...

Embodiment 2

[0035] see Figure 5 and Figure 6 , Figure 5 is a schematic cross-sectional view of the second embodiment of the LED packaging structure of the present invention, Figure 6 yes Figure 5 Top view of the LED package structure shown. The LED packaging structure of the second embodiment is substantially the same as that of the first embodiment, the only difference being that an inner convex wall 32 and an outer convex wall 34 are arranged on the substrate 10, and the radius of the outer convex wall 34 is larger than that of the inner convex wall. 32 radius. One LED chip 20 is arranged in the restricted area of the inner convex wall 32 and fixed on the substrate 10 . Wherein, the inner convex wall 32 is used for coating the phosphor powder layer 50 formed by the mixture of phosphor powder and silica gel, and the outer convex wall 34 is used for molding and encapsulating the colloidal lens 40 . Both the phosphor layer 50 and the colloidal lens 40 use the principle that th...

Embodiment 3

[0037] see Figure 7 and Figure 8 , Figure 7 is a schematic cross-sectional view of the third embodiment of the LED packaging structure of the present invention, Figure 8 yes Figure 7 Top view of the LED package structure shown. The LED packaging structure of the third embodiment is substantially the same as the LED packaging structure of the second embodiment, the only difference being that a plurality of LED chips 20 are arranged in the limited area of the inner convex wall 32 and fixed on the substrate 10 . The sizes of the plurality of LED chips 20 may be the same, or may be a combination of chips of different sizes. The types of the plurality of LED chips 20 can also be different, and a multi-chip module can be composed of chips emitting different lights.

[0038]Compared with the prior art, the present invention can directly carry out the dispensing process on the LED chip to form the sealing lens, and at the same time, the structure of the convex wall is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com