Semiconductor refrigeration vacuum freezing dryer capable of realizing energy recovery

A technology of vacuum freeze-drying and energy recovery, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of unutilized, application limitations, slow heating switching speed, etc., and improve energy utilization efficiency, shorten drying time, and improve drying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

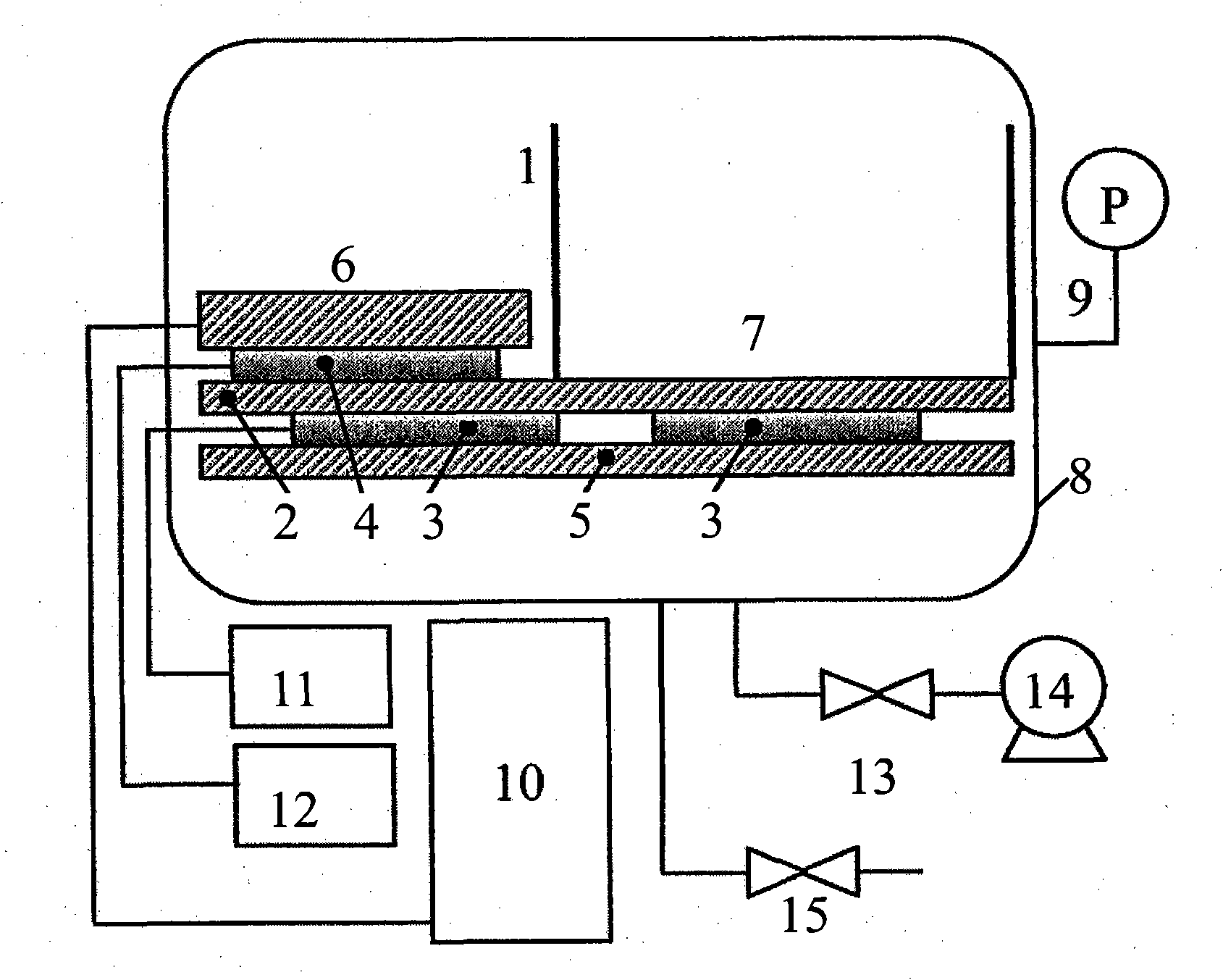

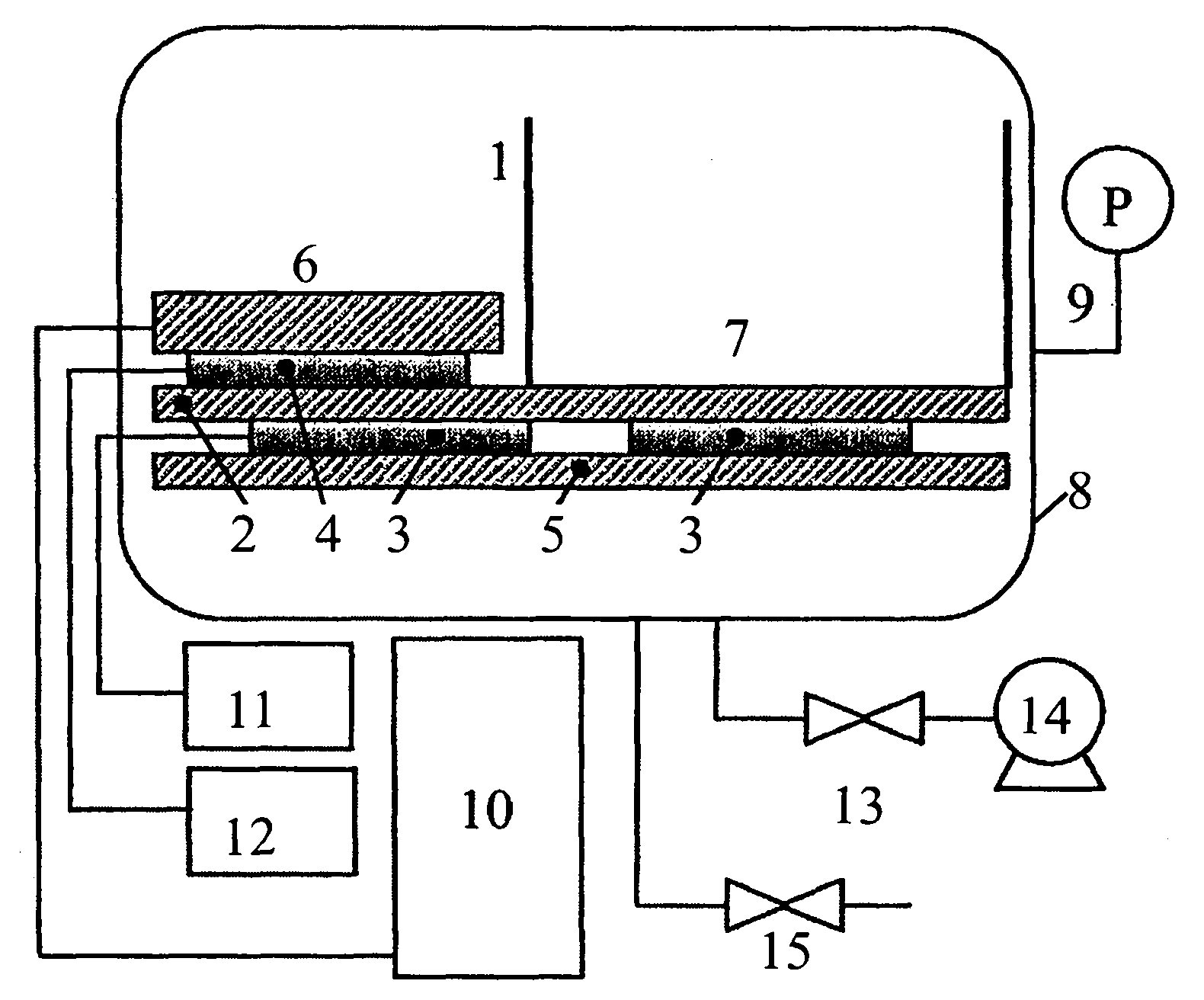

[0014] Such as figure 1 As shown, the annular side wall 1 made of plexiglass is placed on the upper part of the vapor chamber 2, and forms an open container with the upper end surface of the vapor chamber 2. As the material chamber 7, the vapor chamber 2 made of red copper has sufficient Excellent mechanical strength and good heat transfer capacity, the upper end surface of the semiconductor refrigerator I3 is in good contact with the lower end surface of the vapor chamber 2, the lower end surface of the semiconductor refrigerator I3 is in good contact with the water catcher 5, and the water catcher 5 is made of red copper The formed plate-shaped radiator is used as a condenser for the water vapor escaped during the sublimation process. The lower end surface of the semiconductor refrigerator II4 is in good contact with the upper end surface of the vapor chamber 2, and the upper end surface of the semiconductor refrigerator II4 is in contact with the water-cooled radiator 6 Goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com