Motorcycle sound eliminator with dual catalysts

A technology for mufflers and motorcycles, used in mufflers, machines/engines, engine components, etc., can solve the problems of difficult product quality assurance and increased cost, and achieve the effects of simple structure, improved production feasibility, and guaranteed conversion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

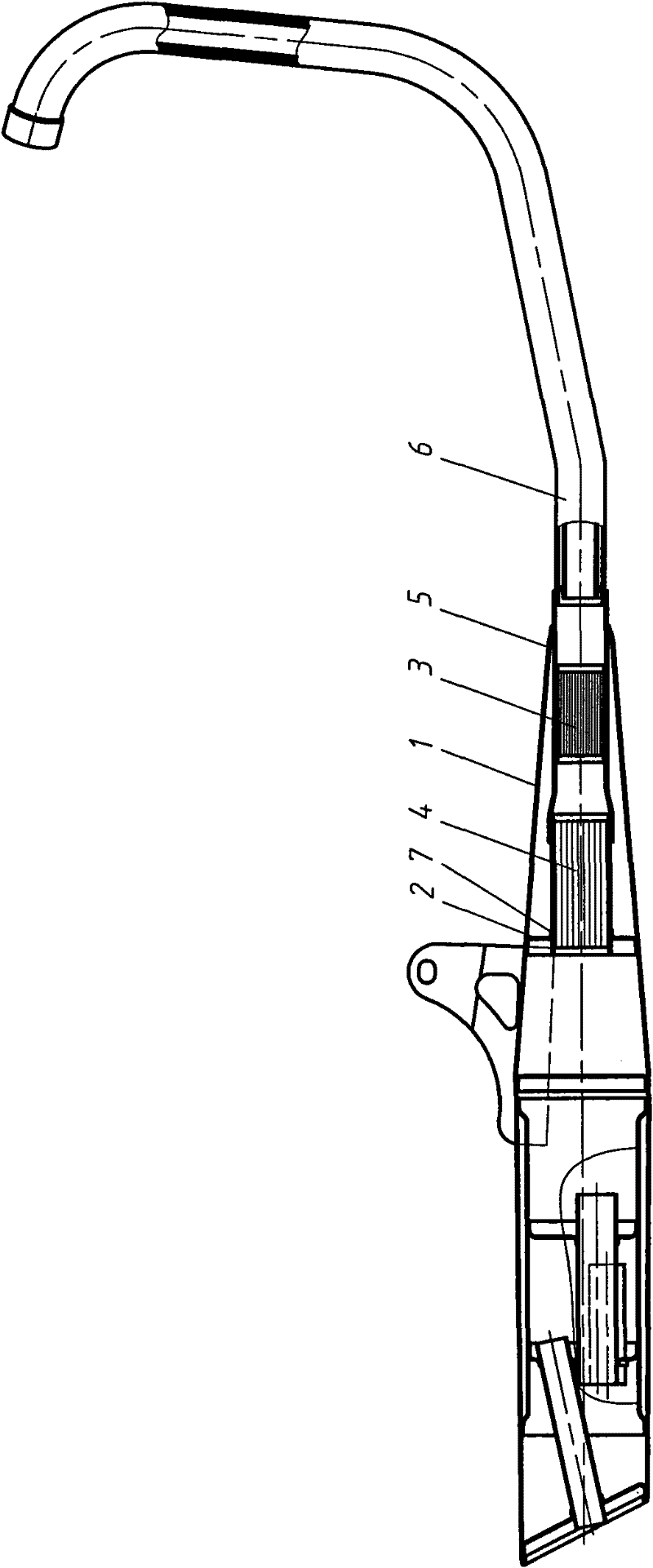

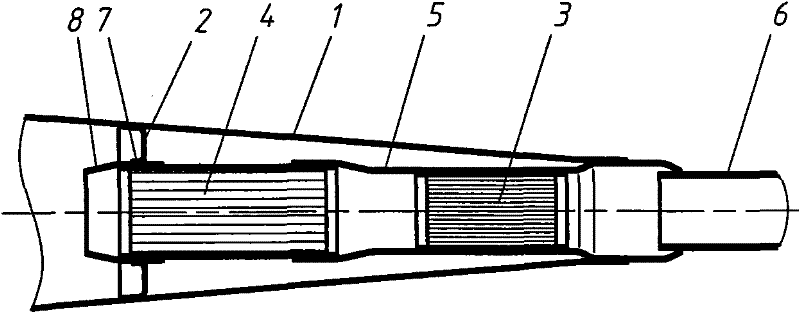

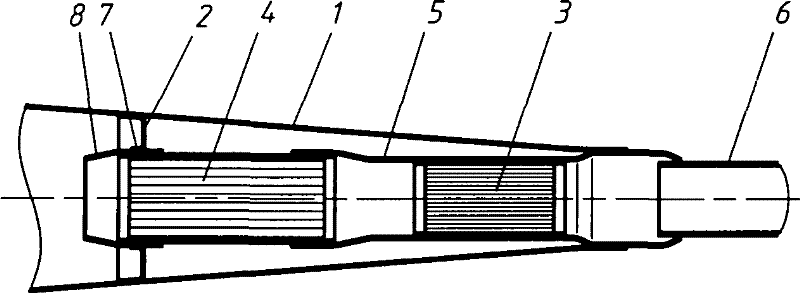

[0014] see figure 2 , figure 2 Only the improved part is involved, and other parts are omitted because they are the same as the existing structure. As can be seen from the figure, the double-catalyst motorcycle muffler of the present invention comprises a muffler body front section 1, a muffler partition 2, a front catalytic converter 3, a rear catalytic converter 4 and a catalytic sleeve 5. The muffler partition 2 is fixed in the front section 1 of the muffler body, and the front catalytic converter 3 and the rear catalytic converter 4 are installed in the front section 1 of the muffler body through the catalyst sleeve 5 . The muffler partition 2 is provided with a hole, the tail of the rear catalytic converter 4 is placed in the hole, and the front part of the catalyst casing 5 passes through the front port of the muffler body front section 1 . The improvement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com