Zinc-iron metal alramenting liquid capable of being recycled at normal temperature

A metal surface and phosphating solution technology, which is applied in the coating process of metal materials, etc., can solve the problems of phosphating, such as sediment and discharge that need to be washed with water, harsh working environment, and uneven film formation, so as to reduce energy consumption and facilitate maintenance , reduce the effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment is formulated by weight ratio by following components:

[0031] Phosphoric acid 14%

[0034] Citric acid 0.56%

[0035] Tartaric acid 0.56%

[0036] Molybdate 0.35%

[0037] water balance

[0038] This embodiment is applicable to the phosphating treatment on the surface of various ferrous metal workpieces before spraying at normal temperature, and the treatment time is 6-15 minutes, wherein the molybdate is sodium molybdate.

Embodiment 2

[0040] The present embodiment is formulated by weight ratio by following components:

[0041] Phosphoric acid 21%

[0043] Zinc nitrate 15.4%

[0044] Citric acid 0.42%

[0045] Tartaric acid 0.35%

[0046] Molybdate 0.56%

[0047] water balance

[0048] This embodiment is applicable to the phosphating treatment before spraying on the surface of various ferrous metal workpieces at normal temperature, and the treatment time is 6-15 minutes, wherein the molybdate is zinc molybdate. .

Embodiment 3

[0050] Phosphoric acid 28%

[0051] Zinc Oxide 4.2%

[0052] Zinc nitrate 17.5%

[0053] Citric acid 0.28%

[0054] Tartaric acid 0.14%

[0055] Molybdate 0.7%

[0056] water balance

[0057] This embodiment is applicable to the phosphating treatment on the surface of various ferrous metal workpieces at room temperature before spraying, and the treatment time is 6-15 minutes, wherein the molybdate is ammonium molybdate.

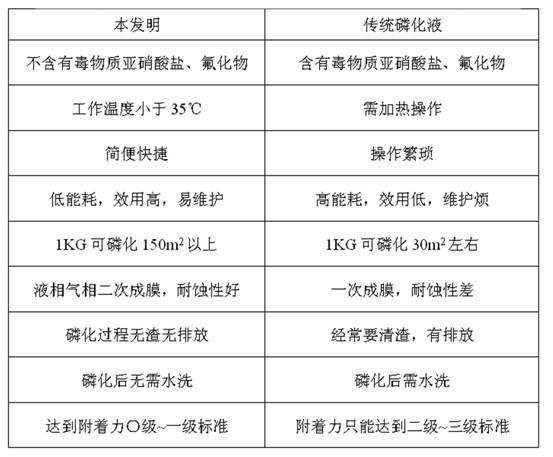

[0058] The following table is that the present invention and the characteristics of each index of traditional phosphating solution are compared as follows:

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com