Coaxial composite welding method of laser spot welding and resistance spot welding

A technology of resistance spot welding and hybrid welding, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as poor welding performance, improve mechanical properties, delay cooling rate, improve absorption rate and welding stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

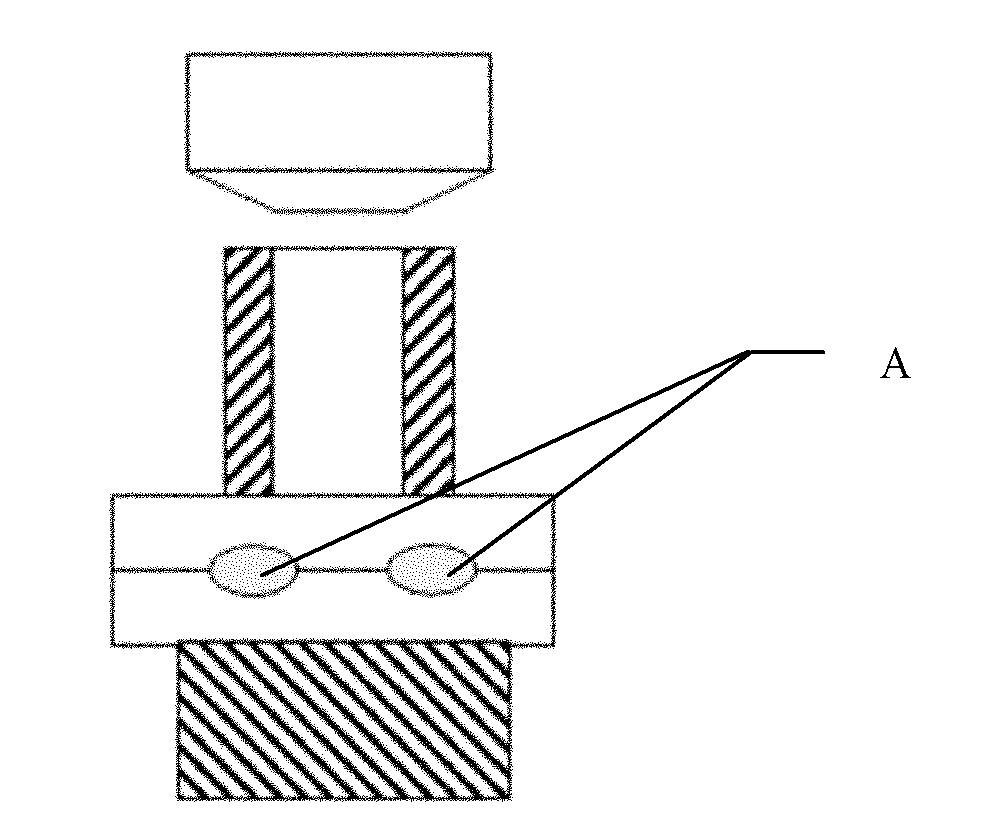

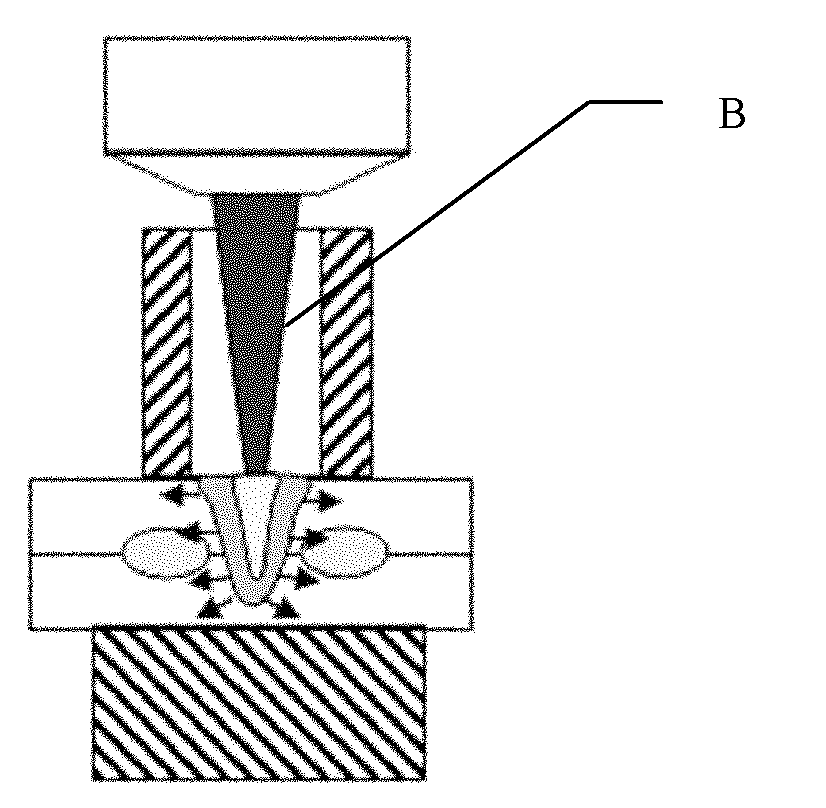

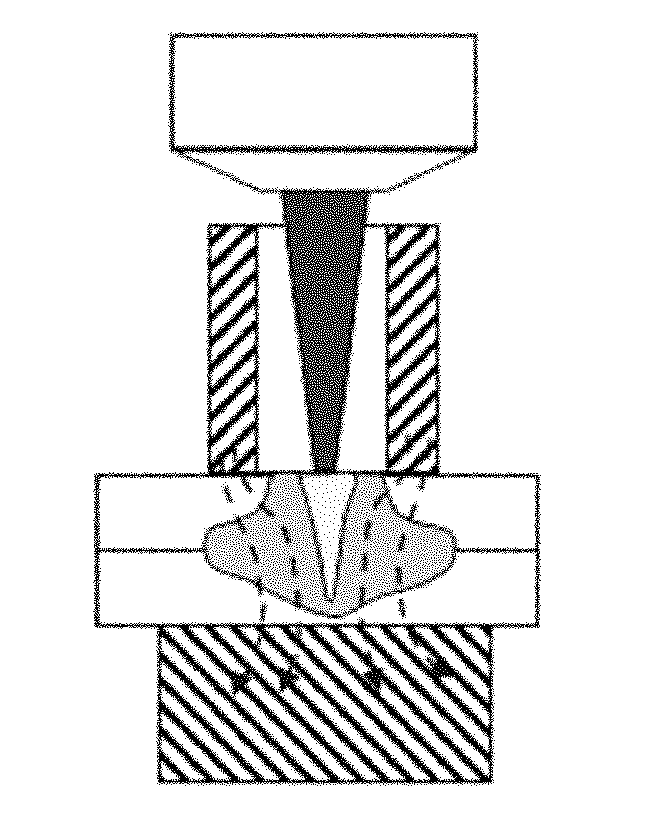

[0017] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the welding method described in this embodiment is based on the existing method of resistance spot welding of the base metal to be welded, the upper electrode in the resistance spot welding method adopts a hollow electrode, and the resistance spot welding of the base material to be welded At the same time, the laser beam passes through the center of the hollow electrode to perform laser spot welding on the base material to be welded, so as to realize the coaxial combination of laser spot welding and resistance spot welding.

[0018] Laser spot welding forms a welding pool and a keyhole on the base metal to be welded, and connects with the molten pool formed by resistance spot welding, finally forming a cross-shaped welding spot.

[0019] The lower electrode in the resistance spot welding method in this embodiment is in the form of an electrode used in a convention...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The outer diameter of the hollow electrode is 13 mm to 30 mm, the inner diameter of the hollow electrode is 3 mm to 15 mm, and the wall thickness of the hollow electrode is greater than or equal to 5mm.

[0025] If the outer diameter of the hollow electrode is too small, the electrode will be easily deformed during the resistance spot welding process, and satisfactory weld formation cannot be obtained; if the inner diameter of the hollow electrode is too small, the laser beam will not pass through.

specific Embodiment approach 3

[0026] Specific embodiment three: this embodiment is a further limitation to embodiment one or two, the welding duration of the welding method is 0.06s to 0.5s, the welding current of resistance spot welding is 2000A to 12000A, the welding of laser spot welding The power is from 100W to 5000W.

[0027] In the laser-resistance spot welding coaxial composite welding process, if the laser power is too large, the heat generated by the laser energy and the plasma radiation generated by the laser welding to the electrode will easily cause the electrode to deform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com