Weft knitting machine and method of knitting using racking of weft knitting machine

A technology of flat knitting machines and knitted fabrics, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of high speed limitation, achieve the effects of preventing yarn surplus, reducing load and improving weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

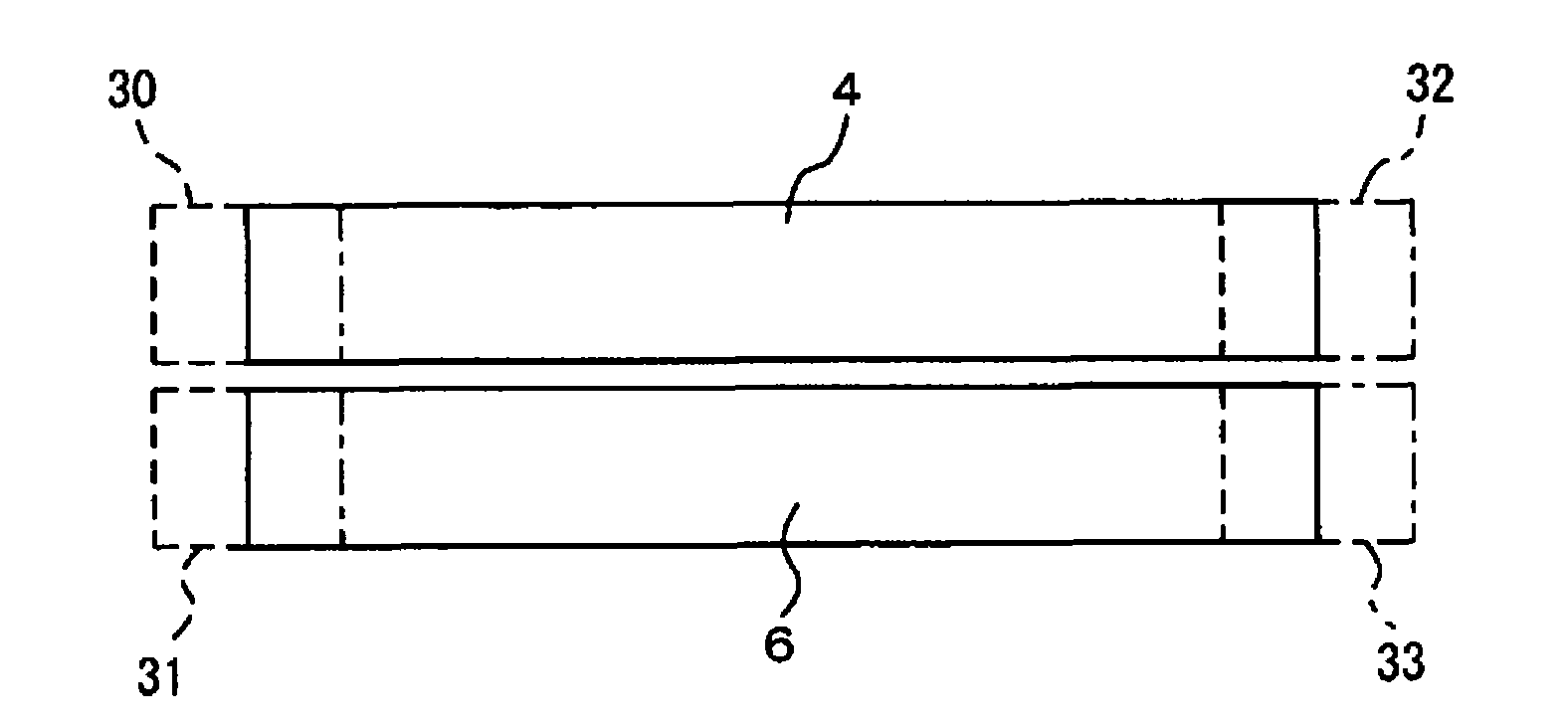

[0047] Figure 1 to Figure 7 The flat knitting machine 2 of the embodiment and the knitting method of the embodiment are shown in . In each figure, 4 and 6 are needle beds, 4 is a rear needle bed, and 6 is a front needle bed. The needle bed 4 can be moved laterally by a motor M2 and a ball screw (not shown), and the needle bed 6 can also be moved laterally by a motor M3 and a ball screw similarly. Assuming that the traverse direction is the longitudinal direction of the needle beds 4 and 6, it is, for example, 1 inch to the right, 1 inch to the left, or 2 inches in total relative to the reference position. The lateral movement of ±1 inch is determined according to the length of the stitches to be moved laterally in one operation, and the needle beds 4, 6 may also be laterally moved in a larger stroke such as ±5 inches. In the embodiment, the needle beds 4 and 6 simultaneously move in the same direction at a constant speed except when the stitches are moved in the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com