Compliant multilayered thermally-conductive interface assemblies and memory modules including the same

A technology for memory modules and interface components, which is applied in the fields of semiconductor/solid-state device components, semiconductor devices, and semiconductor/solid-state device manufacturing, etc., and can solve problems affecting the operation characteristics of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

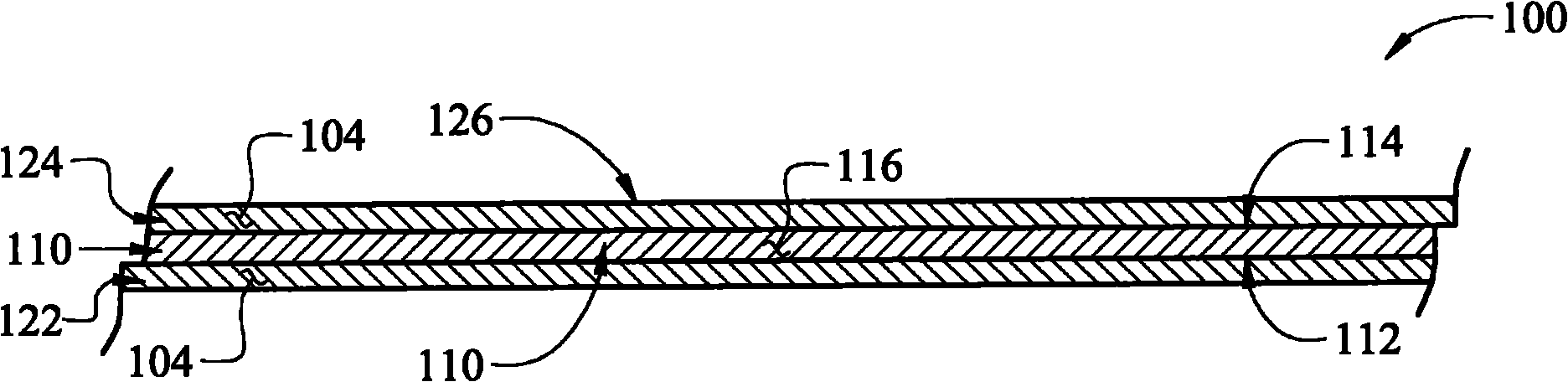

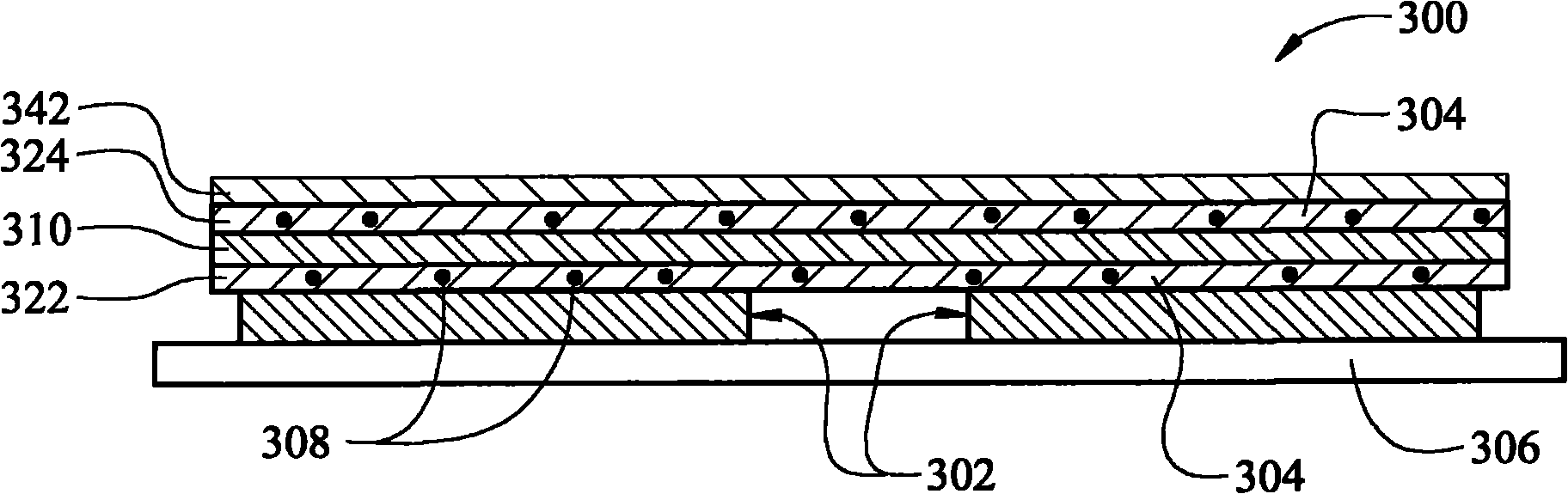

[0029] Because the inventors have recognized in this regard that thermal interface materials provide a limited thermal conduction path, the inventors herein disclose various exemplary embodiments of a thermal interface assembly that includes a flexible heat dissipation material (e.g., that can be perforated flexible graphite sheet, etc.) and one or more layers of soft thermal interface material (eg, thermal interface material disposed on at least one side or opposite sides of the flexible graphite sheet, etc.). Flexible heat dissipation material may generally refer to and include a variety of materials that are flexible equal to or greater than 20 mil thick stamped aluminum sheets and / or 15 mil thick flexible copper stamped sheets, among others.

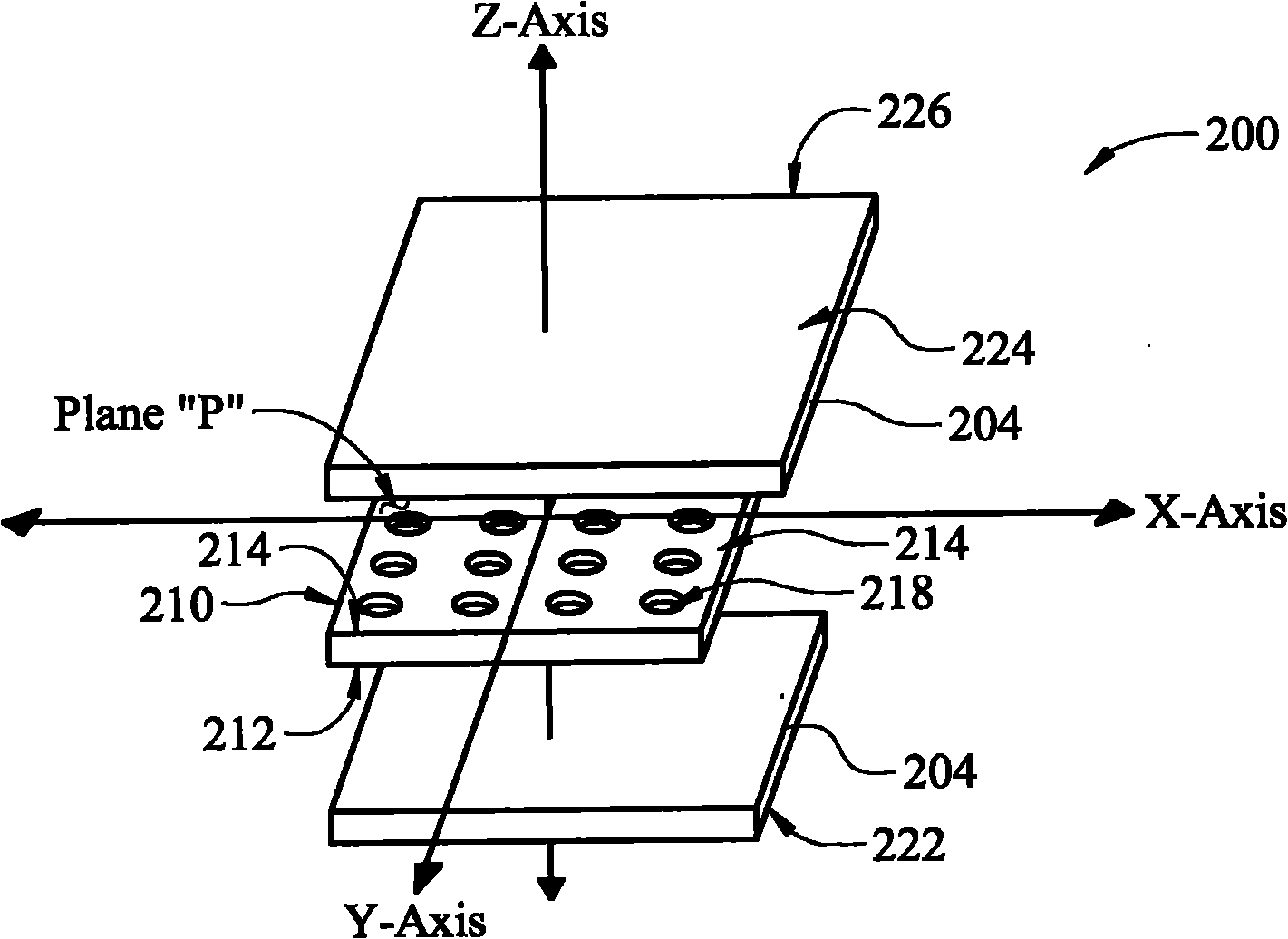

[0030] In flexible heat sink materials, heat is dissipated laterally (e.g., along figure 2 X and Y directions shown in X and Y directions, etc.) so that heat can be transferred from the flexible exothermic material (for example, by co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com