Rheid fermenting cellar and method for producing methane by utilizing rheid fermenting cellar

A fermentation chamber and software technology, applied in the field of biogas production and soft fermentation chambers, can solve the problems that are difficult to achieve industrialization, and achieve the effects that are conducive to development and utilization, speed up gas production, and comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Take the biogas project for living in a small town with a population of 1,000 as an example:

[0074] With crop straws as the main fermentation raw materials, using a medium-temperature fermentation process, the annual output of biogas per cubic meter is about 200 cubic meters.

[0075] Calculated on the basis of 3 to 5 people in each household, the average household biogas consumption is about 500 cubic meters per year. 1,000 households need 500,000 cubic meters of biogas annually. The total volume of the soft fermentation chamber should reach 2,500 cubic meters.

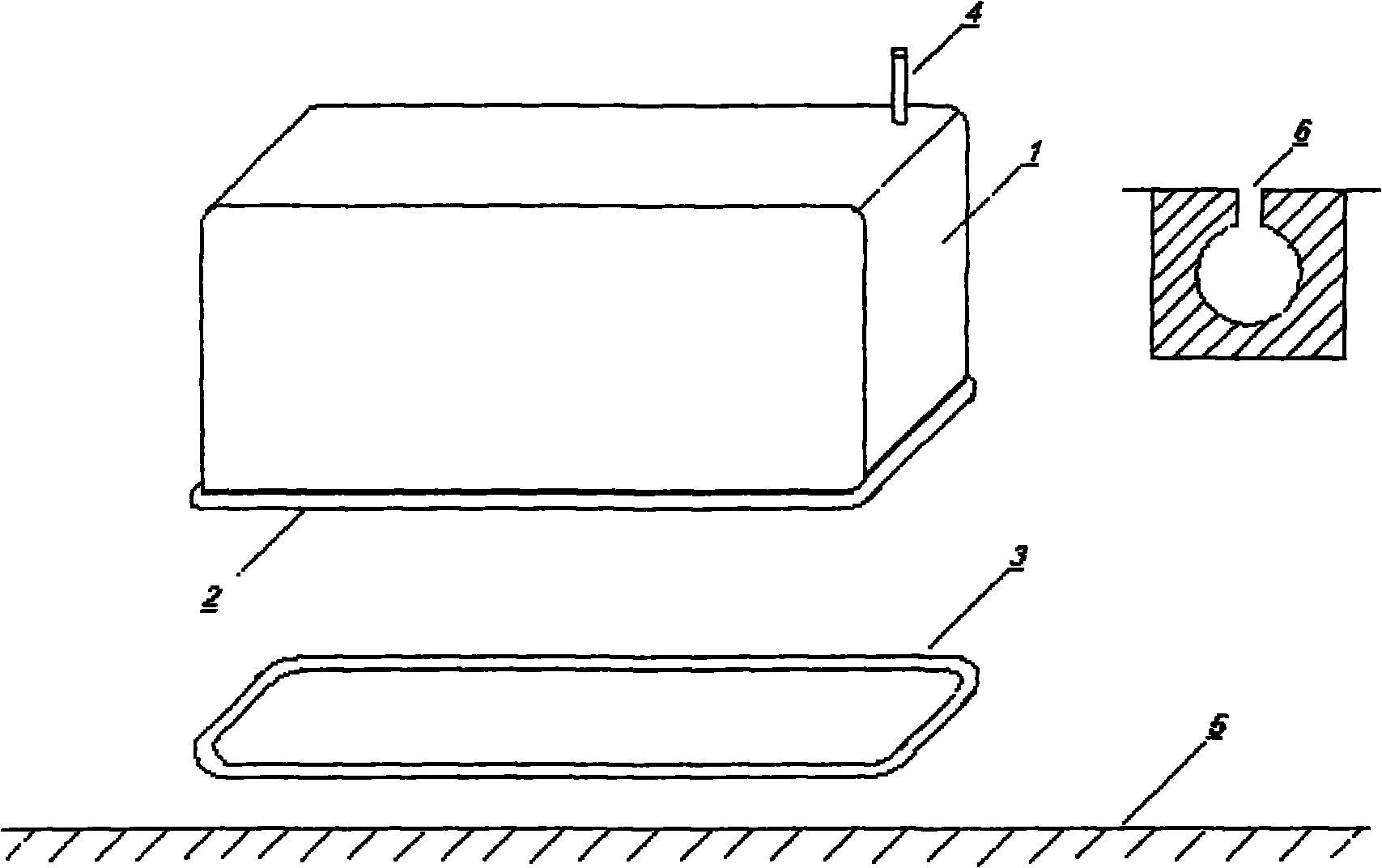

[0076] Inlay a rounded rectangular ring groove (3) with a length of 10 meters and a width of 4.2 meters on the cement floor (5) in the solar greenhouse;

[0077] The sealing cover (1) of each soft fermentation chamber is 10 meters long, 4.2 meters wide, and 3 meters high. The bottom edge is a rounded rectangular inflatable sealing ring (2);

[0078] The air-filled sealing ring (2) is combined with the annular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com