Aliphatic polycarbonate washing coagulation devolatilization method and specific device thereof

A technology of polycarbonate and devolatilization device, which is applied in the field of aliphatic polycarbonate washing, coagulation and devolatilization, can solve the problems that affect the performance of materials, the difficulty of industrialization, and the removal of volatiles is not mentioned, and is suitable for automation. Control, less solid and liquid waste, complete ash and devolatilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

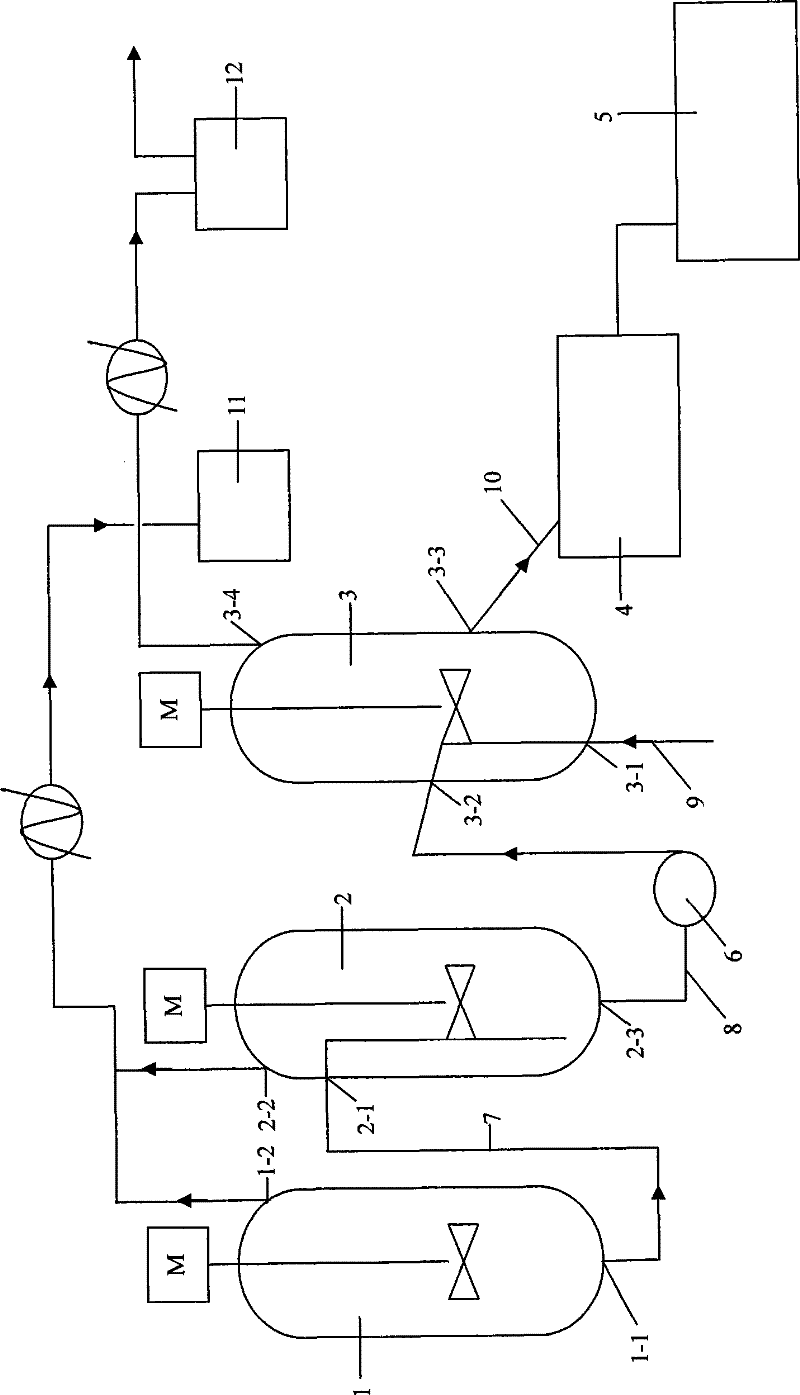

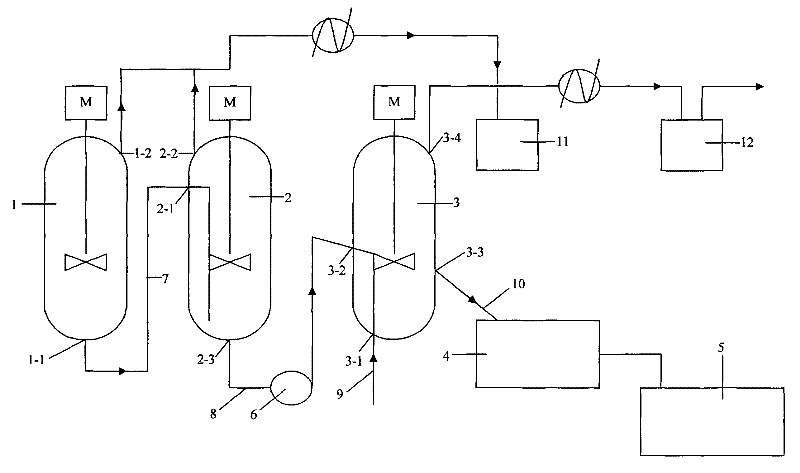

[0048] The aliphatic polycarbonate devolatilization device of embodiment 1 and embodiment 2 is as figure 1 shown. It includes a polymerization reactor 1, a flash glue tank 2, a washing coagulation tank 3, a solid-liquid separation system 4, a polymer drying system 5, a gear pump 6, a monomer recovery tank 11, a monomer-coagulant recovery tank 12, Cooler, condenser and connecting pipes; the lower part of the polymerization reactor 1 is provided with a product outlet 1-1, and the upper part is provided with a gas outlet 1-2; the upper part of the flash glue tank 2 is provided with an inlet 2-1 and a gas outlet 2 -2, the lower part is provided with a liquid outlet 2-3; the lower part of the washing coagulation tank 3 is provided with a washing coagulant inlet 3-1, the middle part is provided with a liquid inlet 3-2 and a liquid outlet 3-3, and the upper part is provided with a gas outlet 3- 4; After the pipeline 7 stretched out from the product outlet 1-1 of the polymerization r...

Embodiment 3

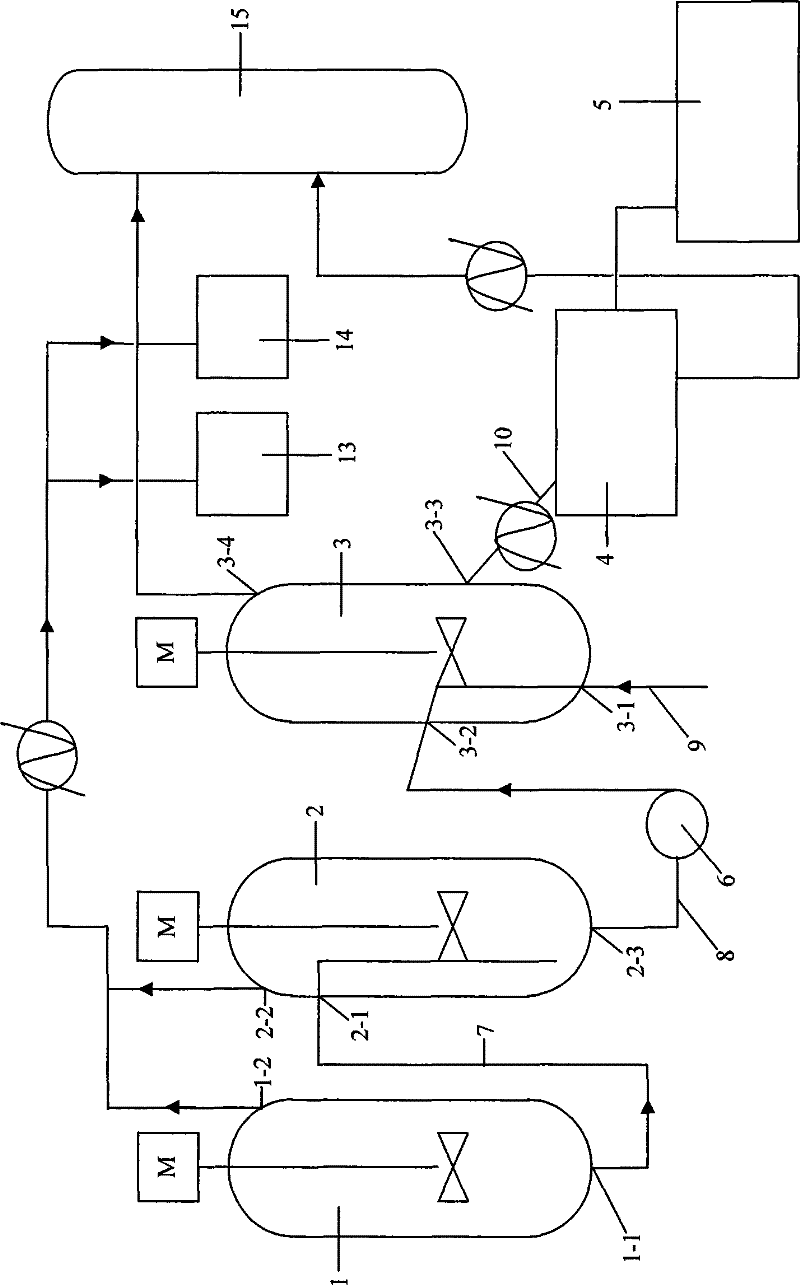

[0049] The aliphatic polycarbonate devolatilization device of embodiment 3 and embodiment 4 is as figure 2 shown. It includes polymerization reactor 1, flash glue tank 2, washing coagulation tank 3, solid-liquid separation system 4, polymer drying system 5, gear pump 6, high-pressure separation tank 13, low-pressure separation tank 14, solvent recovery system 15, Cooler, evaporator and connecting pipes; the lower part of the polymerization reactor 1 is provided with a product outlet 1-1, and the upper part is provided with a gas outlet 1-2; the upper part of the flash glue tank 2 is provided with an inlet 2-1 and a gas outlet 2 -2, the lower part is provided with a liquid outlet 2-3; the lower part of the washing coagulation tank 3 is provided with a washing coagulant inlet 3-1, the middle part is provided with a liquid inlet 3-2 and a liquid outlet 3-3, and the upper part is provided with a gas outlet 3- 4; After the pipeline 7 stretched out from the product outlet 1-1 of t...

Embodiment 2

[0054] Embodiment 2, the application of aliphatic polycarbonate devolatilization device

[0055] Polymerization reactor (5L); flash glue tank (20L); washing coagulation tank (10L); 7°C salt water in the cooler; washing coagulant (75°C ethanol).

[0056] In the polymerization reactor, adopt the method of Chinese patent 00136189.9 to prepare carbon dioxide-propylene oxide-hexane oxide ternary copolymerized aliphatic polycarbonate glue, and use the pressure of the polymerization reactor to enter the glue into the flash devolatilization tank Middle; in the flash devolatilization glue tank, along with the stirring, part of the monomer solvent volatilizes into gas and is removed to obtain concentrated glue; the concentrated glue is continuously sprayed into the washing coagulation kettle by the gear pump; the washing coagulation kettle In the washing process, the washing coagulant is sprayed from the washing coagulant inlet, the monomer solvent (propylene oxide), catalyst and oligom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com