Purification technique for coal glycol rude products

A coal-to-ethylene glycol and crude product technology, applied in the chemical industry, can solve the problems of not effectively reducing the content of aldehydes and ketones, and achieve the effects of high catalyst utilization, energy saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

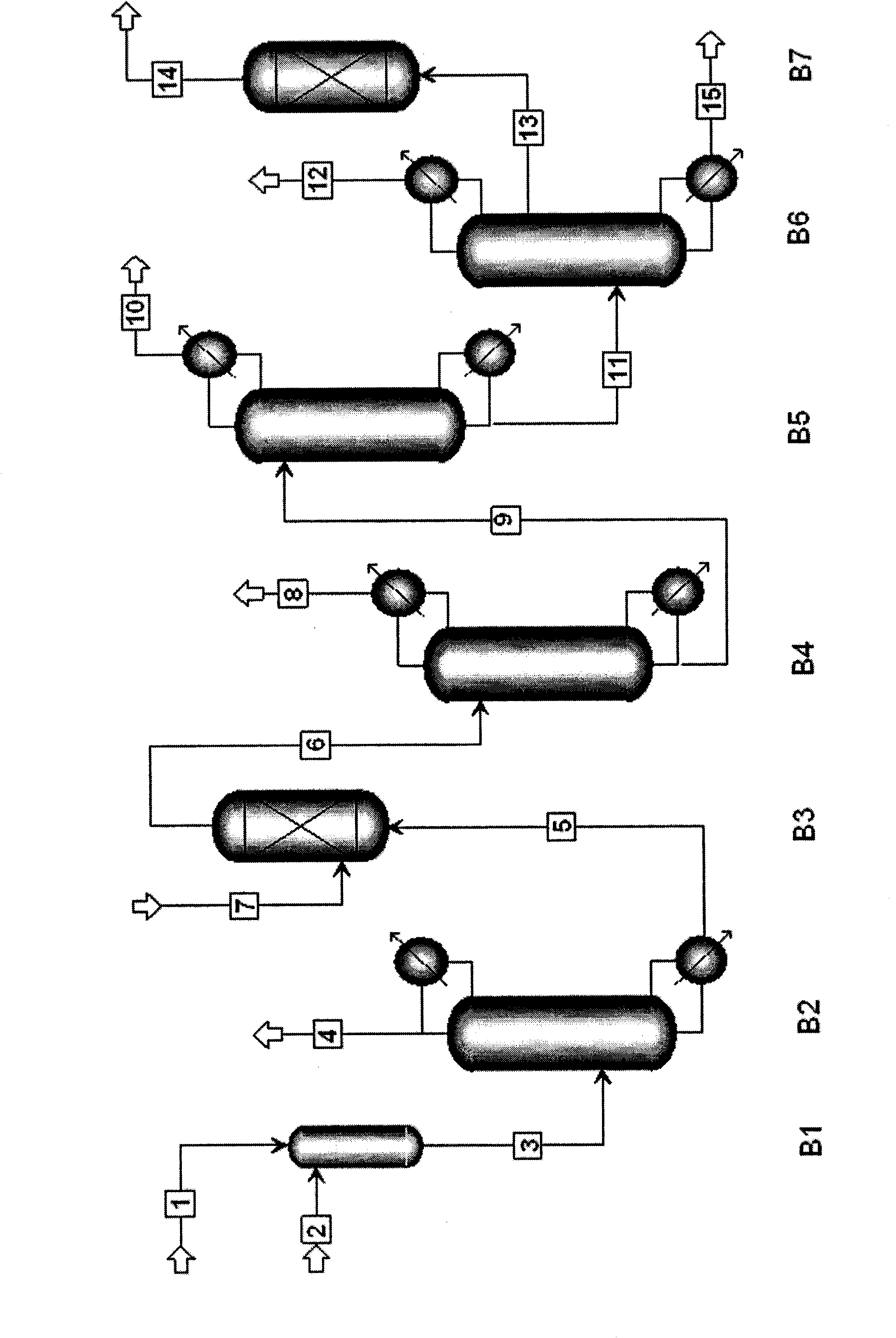

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the coal-based ethylene glycol crude product (1) with a mass percentage of ethylene glycol of 20% is mixed with sodium hydroxide solution (2) and enters the saponification reactor B1. In the sodium hydroxide solution, the mass percent concentration of the solute is 1%, the reaction temperature is 60° C., the reaction pressure is 0.1 MPa, and the mass ratio of sodium hydroxide to ethylene glycol is 1%. The reactor is a tubular reactor, and the single tube is φ25×20000. The saponification reaction product enters the methanol recovery tower (B2).

[0048] The methanol recovery tower (B2) has a diameter of 378mm, 40 trays in total, and is operated under normal pressure. The liquid feed position is between 25 trays, R=3, the liquid feed temperature is 40°C, and the tower top temperature is 61.5 °C, the temperature of the tower kettle is 118.3 °C, and the reflux temperature is 55 °C. Methanol (4) is discharged from the top of the methanol recovery tower (...

Embodiment 2

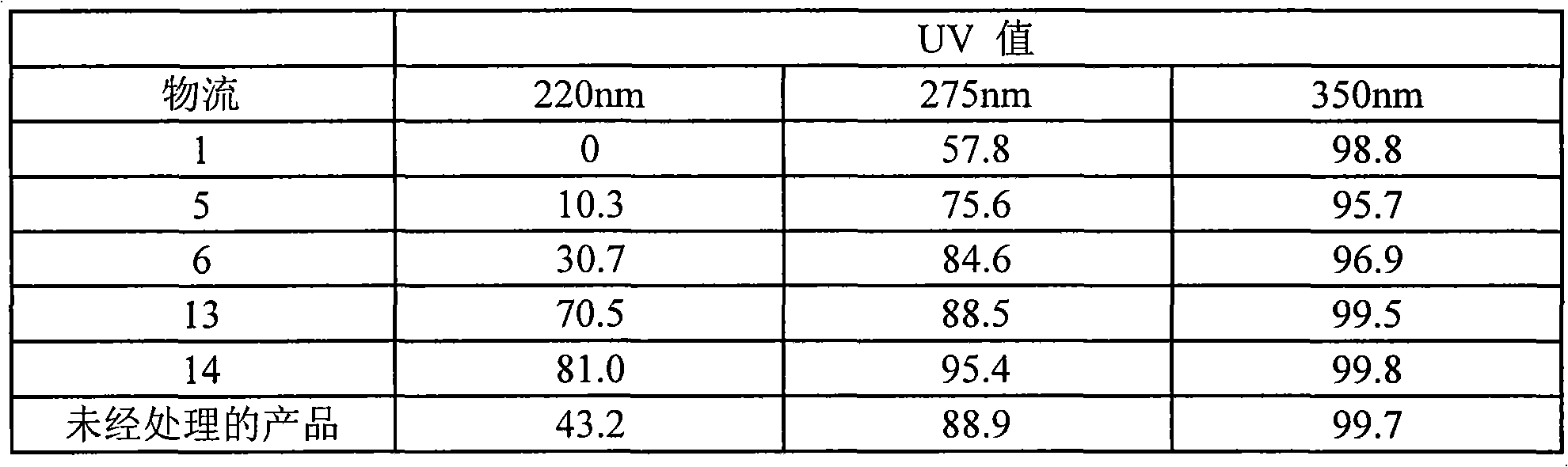

[0060] Liquid-phase hydrogenation uses a commercial Ranney Ni catalyst, the hydrogenation reaction temperature is 120°C, the reaction pressure is 3.0MPa, and the space velocity is 5h -1 , other conditions are as embodiment 1.

[0061] The ultraviolet transmittance of main logistics in the present embodiment is shown in the table below:

[0062] Table 2 UV value of main logistics

[0063]

Embodiment 3

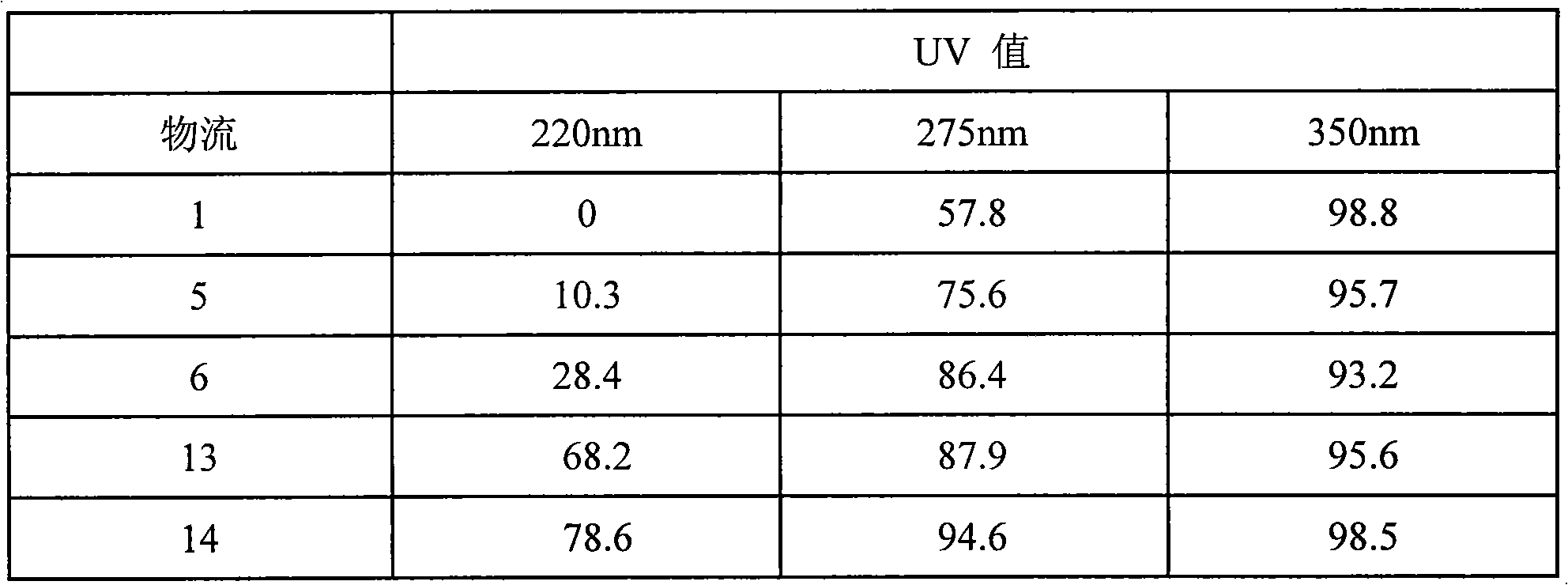

[0065] The resin adsorption tower is made of commercial macroporous adsorption resin, the temperature is 50°C, the pressure is normal pressure or slightly positive pressure, and the space velocity is 2h -1 , other conditions are as embodiment 1.

[0066] The ultraviolet transmittance of main logistics in the present embodiment is shown in the table below:

[0067] Table 3 UV value of main logistics

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com