Method for obtaining high-pearlite high-tenacity nodular cast iron crankshaft

A technology of nodular cast iron and pearlite, which is applied in the field of heat treatment, can solve the problems of insufficient plastic reserve, large consumption of normalizing liquid, and inconvenient machining, and achieve good machining performance, save loss costs, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] CA4102 crankshaft Material requirements: QT800-2, hardness requirements: HB 260-300.

[0030] 1. Melting furnace: 1 ton electric furnace, molten iron weight 1045Kg, plus nodulizer rare earth magnesium 11Kg

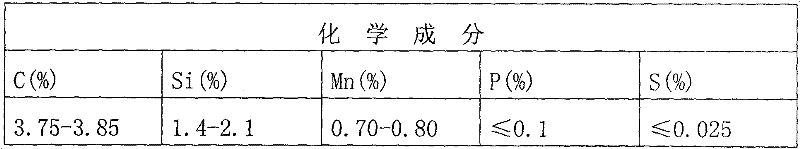

[0031] Chemical composition of materials before spheroidization:

[0032]

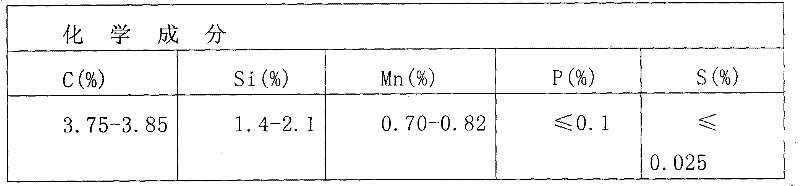

[0033] Chemical composition of the material after spheroidization:

[0034]

[0035] 2. Pouring: The temperature of molten iron coming out of the furnace: 1493°C;

[0036] Casting pouring temperature: 1428°C;

[0037] 3. Unpacking and demoulding: the interval between the pouring of crankshaft castings and the start of unpacking is 13 minutes;

[0038] When unpacking, the casting surface temperature is 899°C; the ambient temperature is 34°C;

[0039] 4. The surface temperature of the crankshaft casting is 849°C when the blowing cooling starts; cool the crankshaft casting to the ambient temperature by blowing blowing;

[0040] 5. Cool the crankshaft casting until the ambient tempera...

Embodiment 2

[0051] YTR4105 crankshaft Material requirements: QT800-2, hardness requirements: HB 240-320;

[0052] 1. Melting furnace: 1 ton electric furnace, molten iron weight 1070Kg, plus nodulizer rare earth magnesium 11Kg

[0053] Chemical composition of materials before spheroidization:

[0054]

[0055] After spheroidizing the chemical composition of carbon, silicon, manganese, sulfur and phosphorus:

[0056]

[0057] 2. Pouring: The temperature of molten iron coming out of the furnace: 1493°C;

[0058] Casting pouring temperature: 1392°C;

[0059] 3. Unpacking and demoulding: the interval between casting pouring and unpacking is 12 minutes and 58 seconds;

[0060] The surface temperature of the crankshaft casting is 891°C when the box is opened; the ambient temperature is 34°C;

[0061] 4. The surface temperature of the crankshaft casting is 860°C when the air blowing is started to cool down; the crankshaft casting is cooled to the ambient temperature by air blowing;

[...

Embodiment 3

[0073] YTR4105 crankshaft material requirements: QT800-2, hardness requirements: HB 240-320;

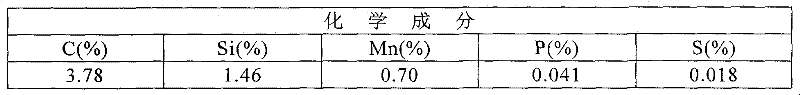

[0074]1. Melting furnace: 1.5 tons of electric furnace, molten iron weight 1485Kg, plus nodulizer rare earth magnesium 15Kg Material chemical composition:

[0075] Chemical composition of materials before spheroidization:

[0076]

[0077] Chemical composition of the material after spheroidization:

[0078]

[0079] Hot metal out of furnace temperature: 1492°C;

[0080] 2. Pouring: Casting pouring temperature: 1389°C;

[0081] The interval between casting pouring and unpacking is 12 minutes and 48 seconds;

[0082] 3. Unpacking and demoulding: when unpacking, the surface temperature of the crankshaft casting is 887°C; the ambient temperature is 34°C;

[0083] 4. The surface temperature of the crankshaft casting is 857°C when the air blowing is started to cool down; the crankshaft casting is cooled to the ambient temperature by air blowing;

[0084] 5. Cool the crankshaft c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com