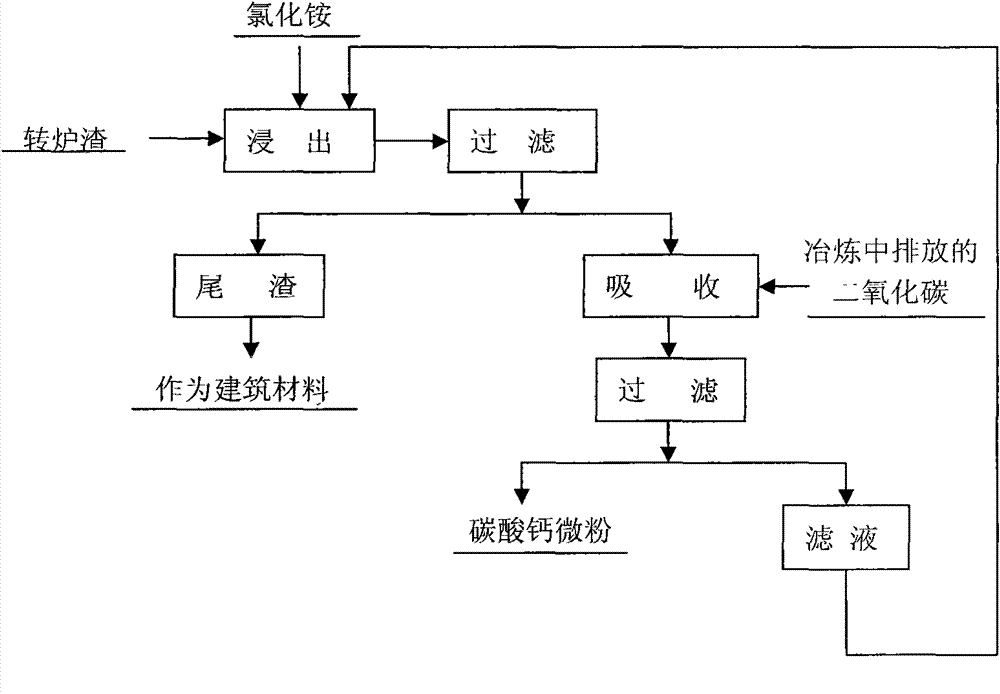

Method for recovering carbon dioxide and preparing calcium carbonate micropowder by utilizing converter slag

A technology of calcium carbonate micropowder and carbon dioxide, applied in the direction of calcium carbonate/strontium/barium, solid waste removal, waste treatment, etc., can solve the problems of high calcium oxide, limit the application of converter slag, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 40 g of converter slag with a calcium oxide content of 45% and a particle size of 800 mesh into the leaching reactor; add ammonium chloride and water into the leaching reactor, stir and raise the temperature, and the quality of the added ammonium chloride is 0.5 times the mass of the converter slag , the quality of water added is 3 times of the quality of converter slag, the stirring speed is 500 rpm, the reaction temperature is 90°C, and the reaction time is 90min; the solution after leaching is filtered and washed, and the calcium oxide content in the filter residue is 28%. Directly used as building materials, the pH value of the filtrate is 10; the carbon dioxide discharged in the smelting is passed into the filtrate under stirring conditions, the flow rate of carbon dioxide is controlled to 1000L / min, the stirring speed is controlled to 500 rpm, and the reaction temperature is 90 ℃, the reaction time is 120min, when the pH value of the solution drops to 8, stop f...

Embodiment 2

[0017] 40g of converter slag with a calcium oxide content of 50% and a particle size of 400 meshes was added to the leaching solution returned in Example 1; ammonium chloride was added to the leaching solution, and the temperature was stirred. The temperature is 200 rpm, the reaction temperature is 50°C, and the reaction time is 60 minutes; the leached solution is filtered and washed, the calcium oxide content in the filter residue is 25%, and it is directly used as a building material, and the pH value of the filtrate is 11; the smelted The carbon dioxide discharged in the process is passed into the filtrate under stirring conditions, the flow rate of carbon dioxide is controlled to be 500L / min, the stirring speed is controlled to be 200 rpm, the reaction temperature is 90°C, and the reaction time is 60min. When the pH value of the solution is reduced to 7.5 stop feeding carbon dioxide; the solution is filtered and separated, and the separated filtrate is returned to the intru...

Embodiment 3

[0019] 40g of converter slag with a calcium oxide content of 50% and a particle size of 60 meshes was added to the leaching solution returned in Example 2; ammonium chloride was added to the leaching solution, and the temperature was stirred, and the quality of the added ammonium chloride was 0.1 times that of the converter slag. The reaction temperature is 100°C, and the reaction time is 10 minutes; the leached solution is filtered and washed, the calcium oxide content in the filter residue is 28%, and it is directly used as a building material, and the pH value of the filtrate is 9; the smelted The carbon dioxide discharged in the process is passed into the filtrate under stirring conditions, the flow rate of carbon dioxide is controlled to be 100L / min, the stirring speed is controlled to be 50 rpm, the reaction temperature is 100°C, and the reaction time is 10min. When the pH value of the solution is reduced to 7 , stop feeding carbon dioxide; filter and separate the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com