Continuous zooming projection lens

A technology of projection lens and zoom group, which is applied in the direction of lens, optics, instruments, etc., can solve the problems of poor manufacturability, long working distance, and high price, and achieve the effects of stable image quality, compact lens structure, and high telecentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

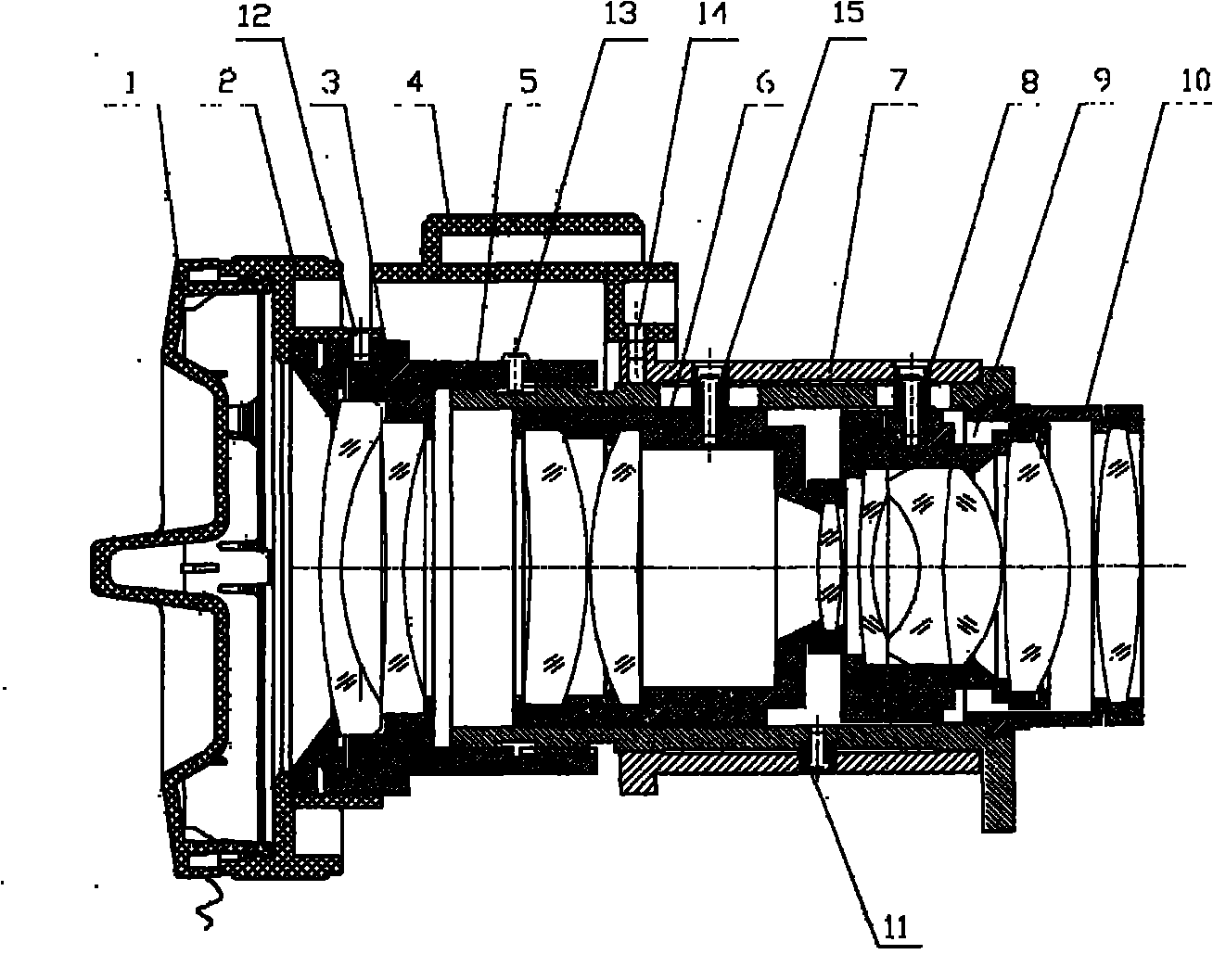

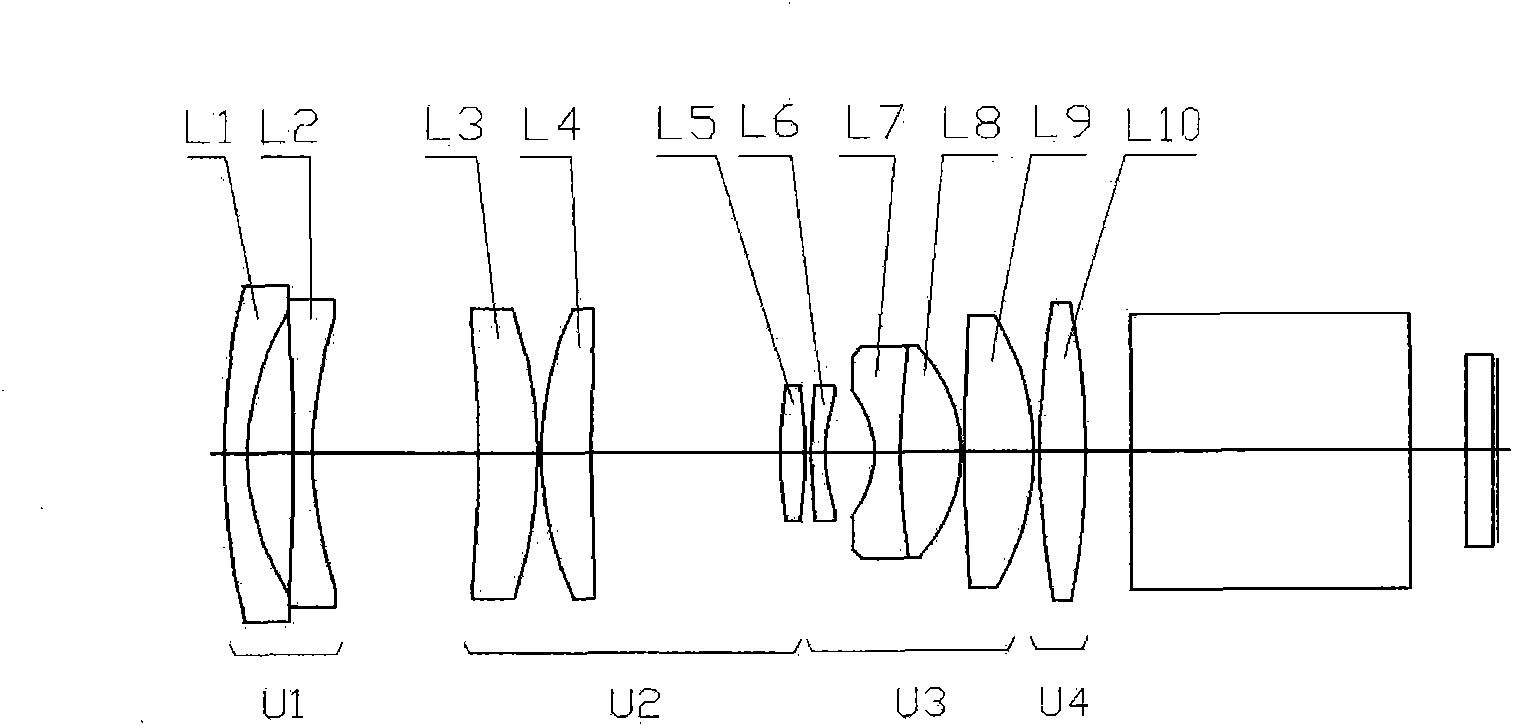

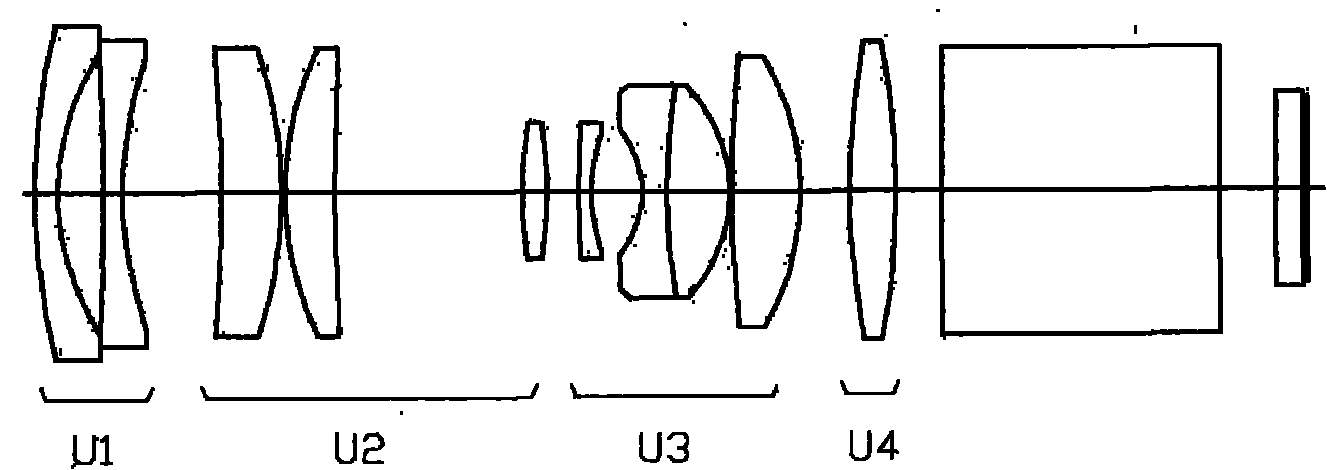

[0032] combine figure 1 , see figure 2 , image 3, the continuous zoom projection lens of the present invention, the main components include a lens cover 1, a focusing handwheel 2, a focusing lens barrel 3, a zooming handwheel 4, a guide barrel 5, a zoom lens barrel 6, a cam curve barrel 7, a roller guide Nail 8, compensation lens barrel 9, fixed lens barrel 10, roller guide nail 11, connecting screw 12, focus limit screw 13, connecting pin 14, roller guide nail 15 and optical system lens group. Among them: the focusing lens barrel 3 is connected to the front end of the guide tube 5 through threads, and the front part is set with a focusing hand wheel 2, and the two are connected together by a connecting screw 12, and the focusing ring 2 can be rotated to drive the focusing lens The cylinder 3 rotates accordingly, and moves axially relative to the guide cylinder 4 to realize the focusing function of the focusing group U1. In the position groove, the two ends of the limit g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com