Preparation of nano gel immobilized multienzyme system and application thereof in synthesizing 1,3-propylene glycol

A technology of nanogel and multi-enzyme system, applied in the direction of immobilized on or in the inorganic carrier, multi-enzyme system, fermentation, etc., can solve problems such as conformational changes and molecular movement restrictions, enzyme activity reduction, and damage to the microenvironment. Achieve the effect of reducing the influence of diffusion, inhibiting agglomeration, and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

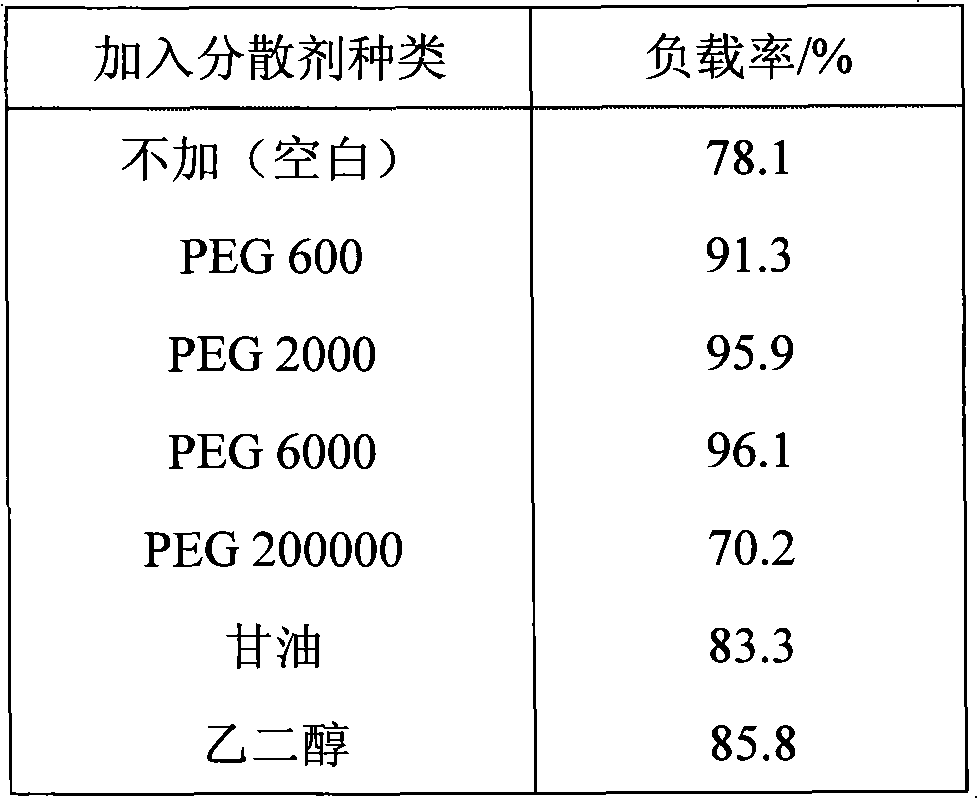

[0032] Embodiment one different alcohol dispersants to TiO 2 load factor effect

[0033] Bacteria: Klebsiella pneumoniae (K.pneumoniae)

[0034] Take 1000mL fermentation broth to collect the bacteria by centrifugation, wash and weigh, add 10 times the mass of 0.9% normal saline, mix well, ultrasonically crush in an ice bath environment, and centrifuge to obtain crude enzyme liquid, which is precipitated with ammonium sulfate with a saturation of 50% , after desalting by dialysis, a multi-enzyme system solution with a concentration of 20.0 g / L was prepared with Tris-HCl buffer solution.

[0035] Weigh 50mg TiO respectively 2 (Particle size 16nm, specific surface area 280m 2 / g) Nanocarriers were put into No. 1-7 test tubes, No. 1 test tube had no dispersant, and 5mL Tris-HCl buffer solution was used as a blank, and ultrasonically dispersed for 30min. Add 5mL of different alcohol dispersant solutions to No. 2-7 test tubes, and ultrasonically disperse for 30min. Then add 5mL...

Embodiment 2

[0045] Example 2 Effects of Different pH Loading Processes on the Loading Rate of Glycerol Dehydrogenase Loaded on Nanogel Carriers

[0046] The preparation of the multi-enzyme system solution was the same as in Example 1.

[0047] With glycerol as dispersant, weigh the same amount of TiO 2 (Particle size 16nm, specific surface area 280m 2 / g) 12 parts of powder, add different pH Tris-HCl buffer solutions (pH=5.0~10.0), ultrasonically disperse for 30 minutes, add a certain amount of enzyme solution, shake and adsorb in a shaker at 37°C for 1 hour, take it out and centrifuge at 8000rpm After 10 minutes, the lower precipitate was washed with Tris-HCl buffer solution until the supernatant was free of protein, and the washing liquid and supernatant were combined for analysis of the enzyme loading rate under different pH conditions. The average value of two parallel samples was taken, and the experimental results are shown in Table 2.

[0048] Table 2 Effects of different pH loa...

Embodiment 3

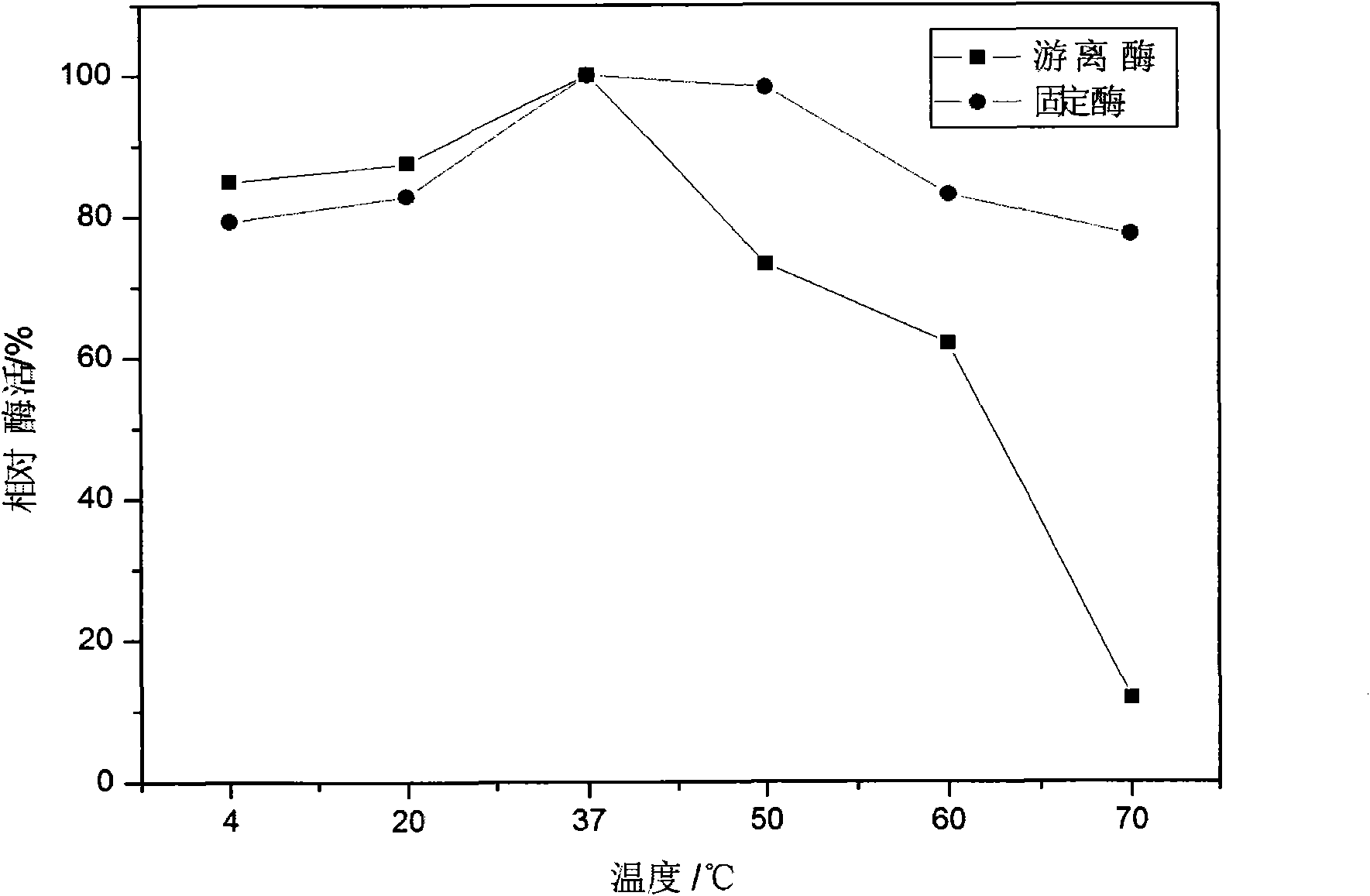

[0051] The thermostability of embodiment three nano-gel immobilized multi-enzyme system

[0052] Bacteria: Klebsiella pneumoniae (K.pneumoniae)

[0053] Glycerol dehydrogenase GDH enzyme activity assay: 5mL GDH reaction solution (containing 30mmol / L (NH 4 ) 2 SO 4 , 0.2mol / L glycerol, 2mmol / L NAD + , 1μmol / L (NH 4 ) 2 Fe(SO 4 ) 2 , prepared with potassium carbonate buffer solution with pH = 11) at 37°C, add the enzyme used in the experiment to start the reaction, react at a constant temperature in a shaker for 40 minutes, transfer to a centrifuge tube and centrifuge at 8000r / min for 10 minutes, and the supernatant in Absorbance A was measured at 340 nm. One enzyme activity unit (U) is the amount of enzyme required to consume 1 mol of substrate in one minute under the conditions.

[0054] The preparation of the multi-enzyme system solution was the same as in Example 1.

[0055] Weigh a certain amount of TiO 2 For powder, use glycerol as dispersant, ultrasonically dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com