Complex microbial inoculum for swine production by fermentation bed started quickly at low temperature and preparation method thereof

A compound microbial inoculum, a fast-start technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of shortage, high cost of raising pigs in fermentation beds, unstable production, etc. The effect of solving environmental pollution and heating up quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Bacillus subtilis, Trichoderma spp, Rps.globiformis, Lactobacillus acidophilus, Saccharomyces cerevisiae and Streptomyces ) composed of 6 strains in total.

[0032] Bacterial agent preparation method: the above-mentioned 6 strains of functional microorganisms are inserted into the prepared six seed culture media according to the inoculation amount of 5% by volume percentage and cultivated respectively. The aerobic bacteria were sealed with three layers of thick sealing film, and cultured in a constant temperature incubator at 35°C for 72h, and the rest of the aerobic bacteria were sealed with two layers of 10μm gas-permeable membranes, and cultured in a constant temperature shaking culture bed at 32°C for 48h-72h. During the period, the number of viable bacteria in each bacterial culture solution was detected separately, and the number of viable bacteria in each bacterial culture was ≥ 1×10 8 After each / ml, take out seed liquid, by volume ratio is Trichoderma: Bacillus...

Embodiment 2

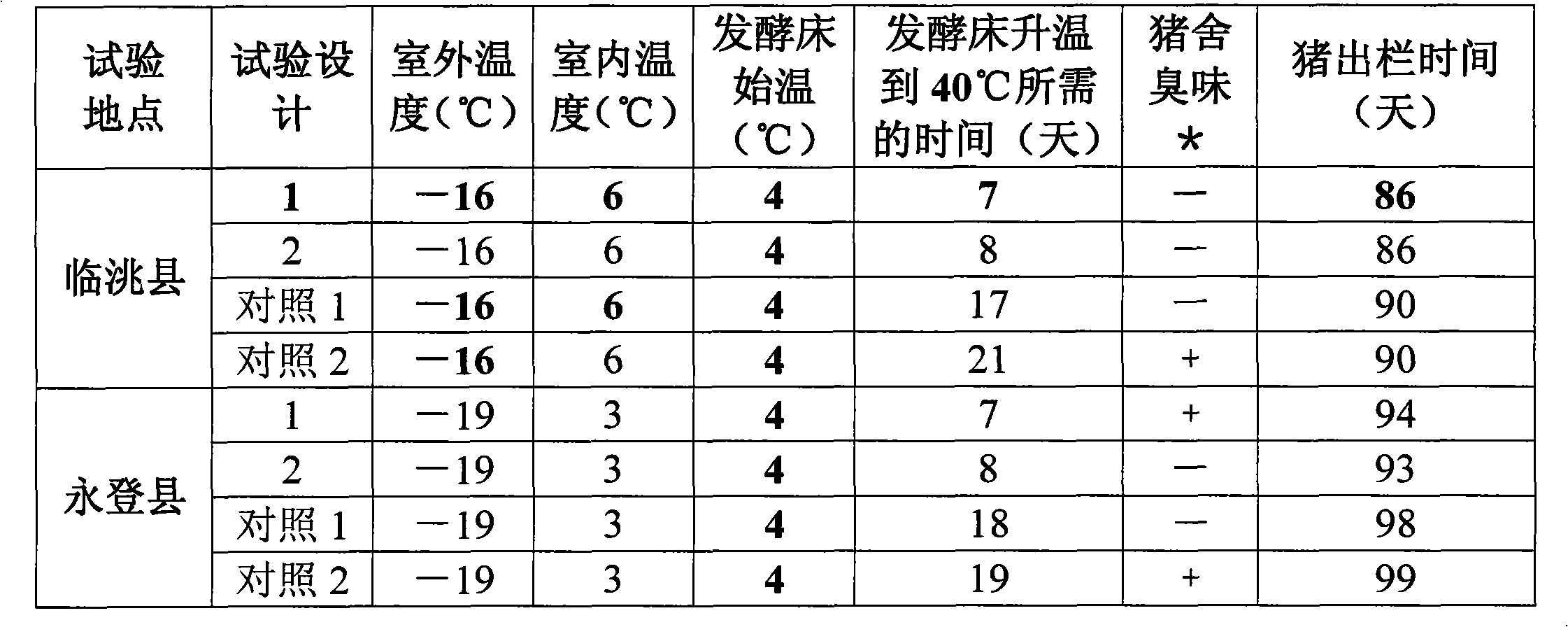

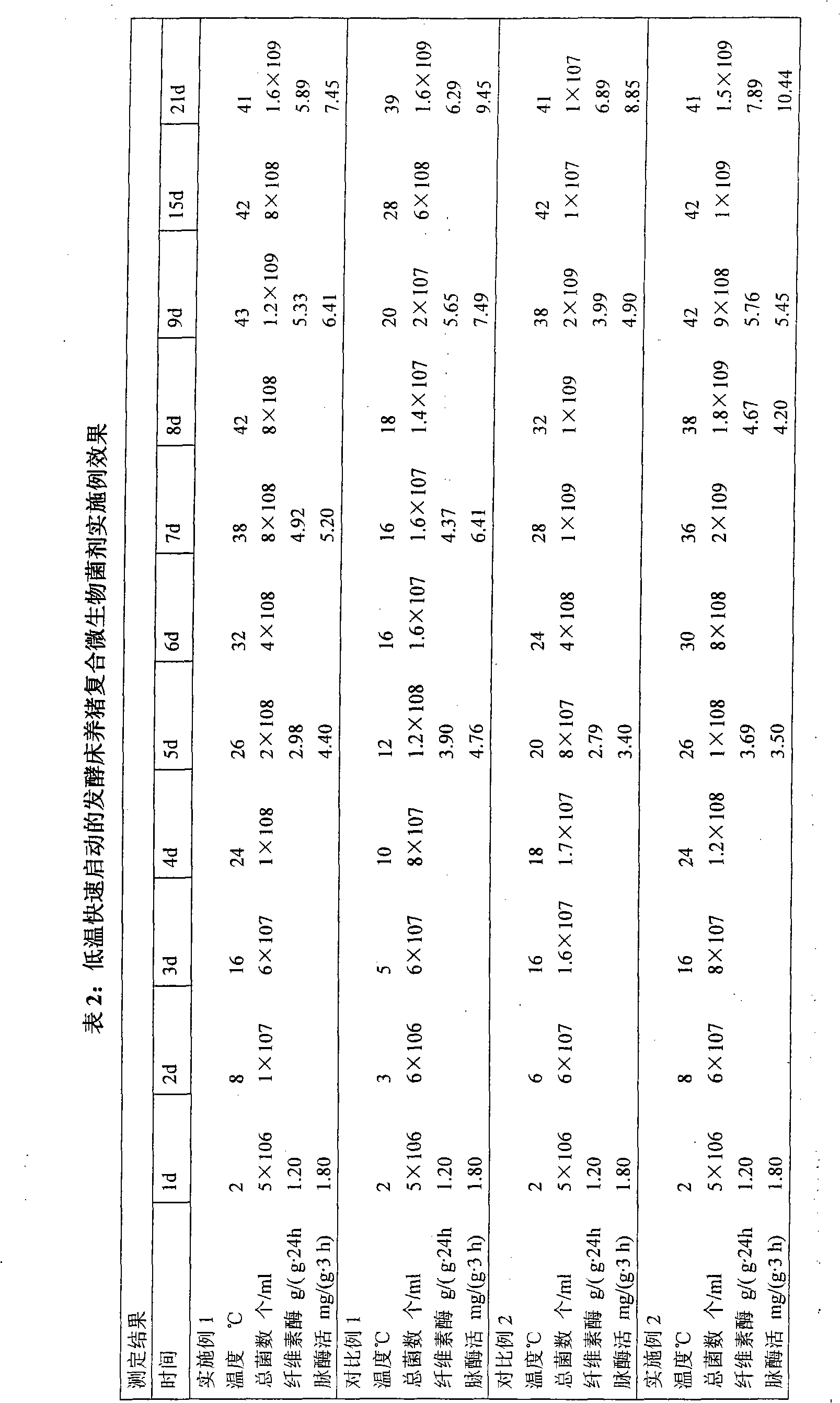

[0041] Repeat embodiment 1, following difference is arranged: by Trichoderma: Bacillus subtilis: Rhodopseudomonas sphaeroides: Lactobacillus acidophilus: Saccharomyces: Streptomyces=15%: 20%: 20%: 15%: 15% : 15%, measured under the same conditions in Example 1, see Table 1 for details.

[0042] The measurement results:

[0043] Pigs began to enter on the 8th day, and the continuous pig production in the normal fermentation bed was carried out. See Table 2 for details.

Embodiment 3

[0045] Repeat embodiment 1, have following difference: by Trichoderma: Bacillus subtilis: Rhodopseudomonas sphaericus: Lactobacillus acidophilus: Saccharomyces: Streptomyces=18%: 18%: 19%: 15%: 15% : 15%, measured under the same conditions in Example 1, see Table 1 for details.

[0046] Measuring results: the pigs were fed on the 6th day, and the continuous pig production in the normal fermentation bed was carried out, see Table 2 for details.

[0047] In order to prove the efficacy of the embodiments of the present invention, comparative examples are specially set up for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com