Method for preparing microorganism agent for increasing production of oilfield microorganisms or protecting environment

A microbial inoculum and microorganism technology, which is applied in the preparation of microbial inoculum powder products and the field of preparation of microbial solid inoculants, can solve the problems of difficulty in guaranteeing microbial activity, large injection amount, and difficulty in realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of microbial agent based on a single strain

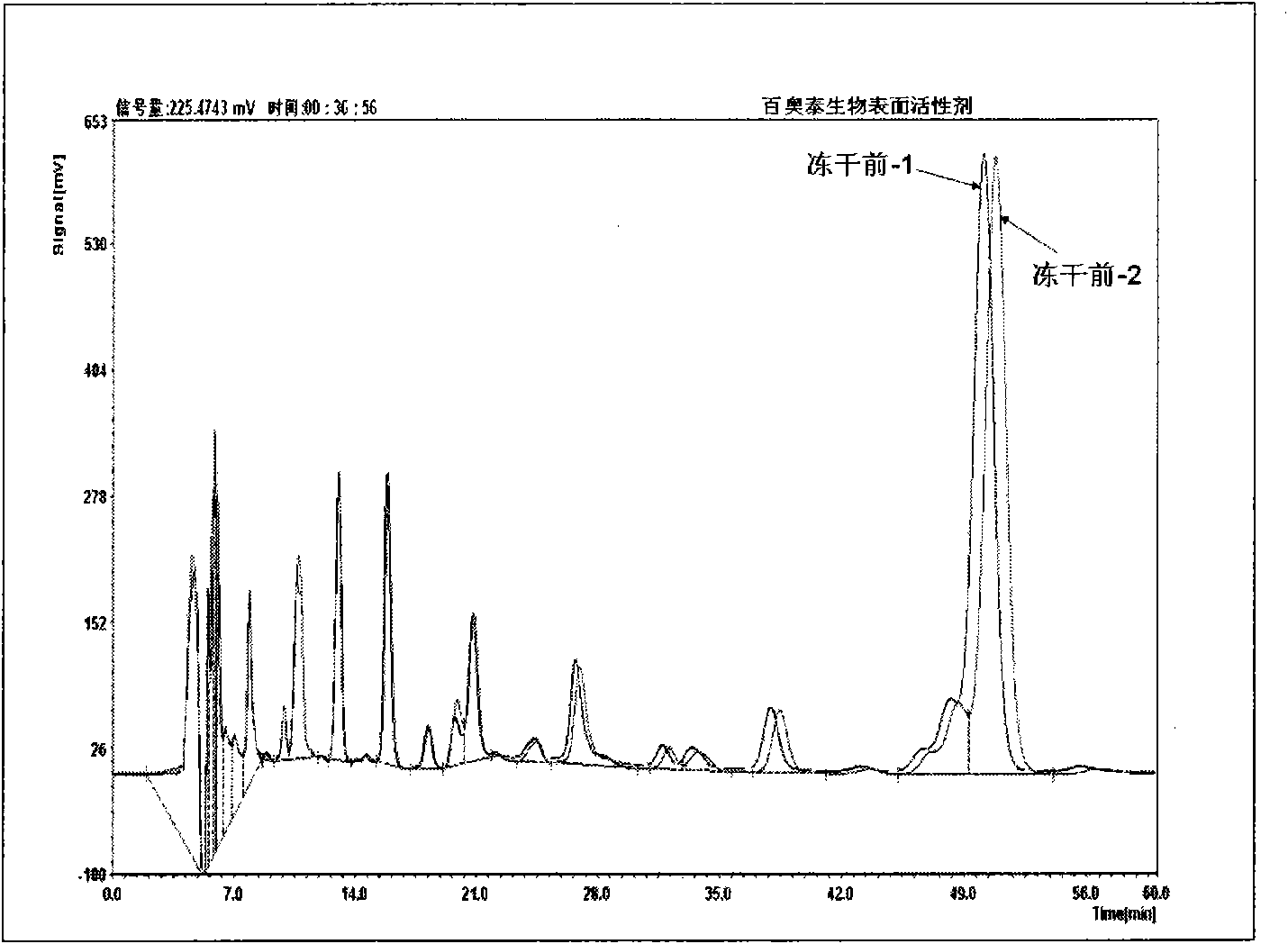

[0037] The target microorganism selected in this example is a strain of Bacillus subtilis (ATCC No. 21332) that produces surfactants, which can be used for microbial flooding in oil production engineering.

[0038] 1. Medium: select LB medium, autoclave at 121°C for 20 minutes, and use it for later use;

[0039] The LB medium is composed of 1% peptone, 0.5% yeast powder, 0.5% sodium chloride, and the balance is water, and has a natural pH value.

[0040] 2. Shake flask culture: inoculate the target bacteria into LB liquid medium, and carry out shaking flask culture. The conditions are: temperature 50℃, rotation speed 150rpm, 30% liquid volume in triangular flask, and cultivation time 12h;

[0041] 3. Fermentation in the seed tank, transfer the shake flask liquid of the target bacteria into the seed tank according to the inoculum of 2%, and carry out fermentation culture. The conditions are: tank temperature 50℃,...

Embodiment 2

[0053] Example 2: Preparation of microbial agents based on mixed strains

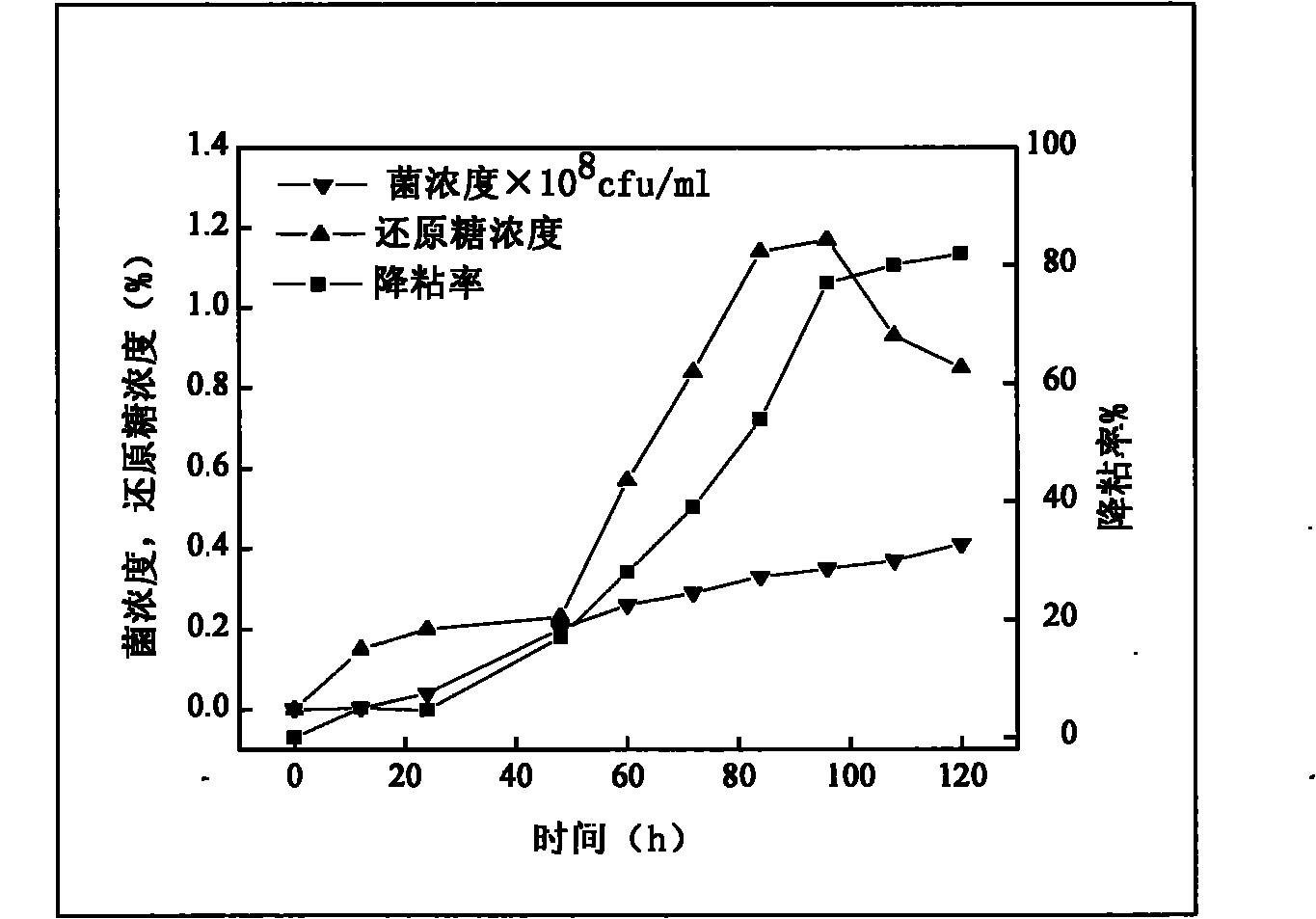

[0054] The target microorganism selected in this example is a complex of Bacillus subtilis (ATCC No. 21332), Bacillus licheniformis (ATCC No. 39307), and Pseudomonas aeruginosa (ATCC No. 9027). This complex bacteria has a certain The ability to degrade xanthan gum.

[0055] 1. Medium: select LB medium, autoclave at 121°C for 20 minutes, and use it for later use;

[0056] The LB medium is composed of 0.8% peptone, 0.3% yeast powder, 0.5% sodium chloride, and the balance is water, with a natural pH value.

[0057] 2. Shake flask culture: inoculate the target bacteria into LB liquid medium, and carry out shaking flask culture. The conditions are: temperature 37℃, rotation speed 160rpm, volume of liquid in triangular flask 20%, culture time 12h;

[0058] 3. Fermentation in the seed tank, transfer the shake flask liquid of the target bacteria into the seed tank according to the inoculum of 3%, and carry out the ferme...

Embodiment 3

[0070] Example 3: Preparation of microbial agents based on mixed strains

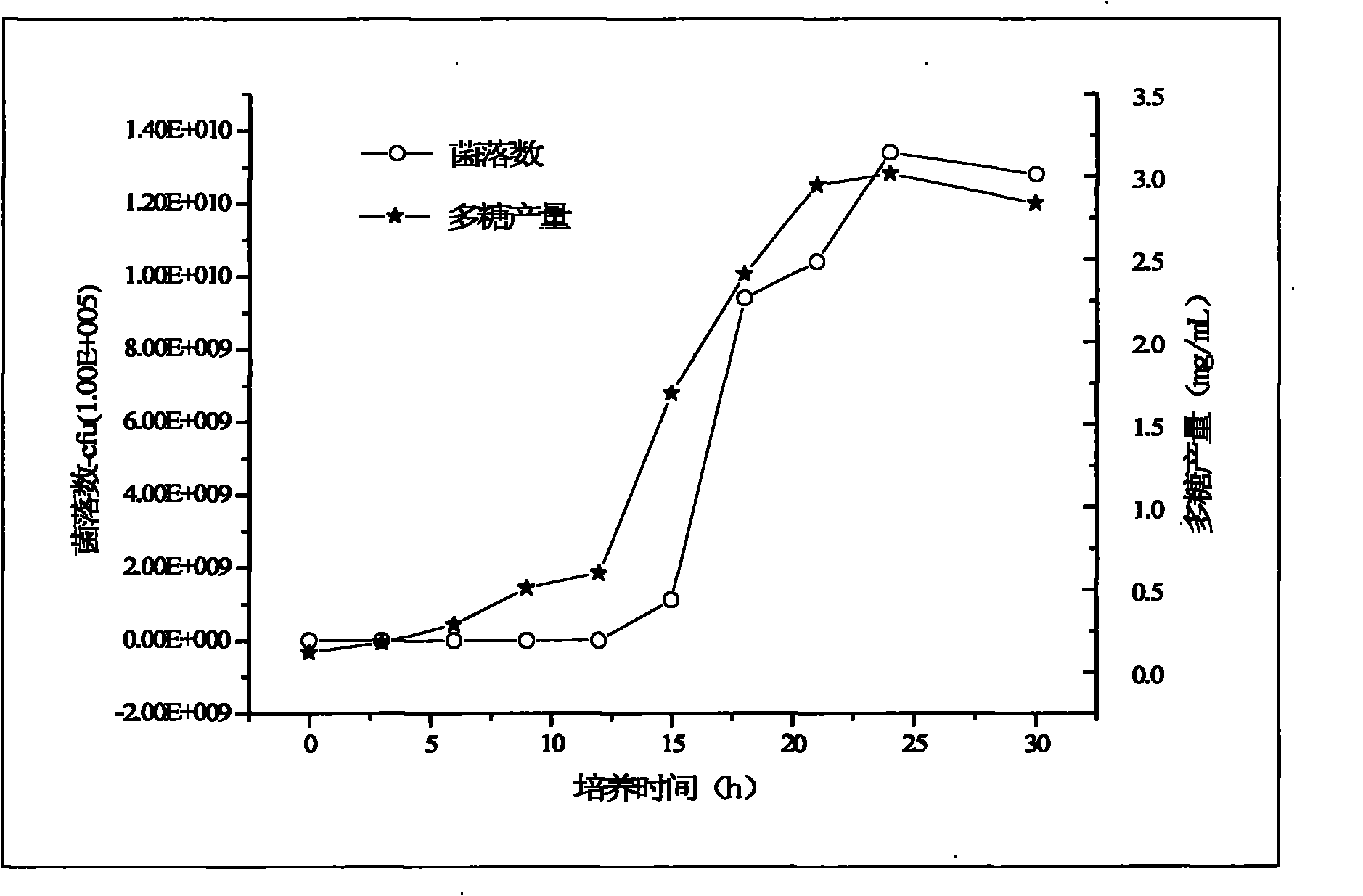

[0071] The target microorganisms selected in this example are a complex of Bacillus subtilis (ATCC NO. 21332), Bacillus licheniformis (ATCC NO. 39307), and Arthrobacter paraffineus (ATCC NO. 19558) This compound bacteria has a certain ability to produce biopolymers and can be used for profile control and water shutoff in the process of oil exploitation.

[0072] 1. Medium: select glucose 2% + basic inorganic salt medium, autoclave at 115°C for 15 minutes, and use it for later use;

[0073] The LB medium is composed of 1% peptone, 0.5% yeast powder, 0.5% sodium chloride, the balance is water, and the pH value is 6.0.

[0074] 2. Shake flask culture: inoculate the target bacteria into the pre-prepared liquid medium, and carry out shaking flask culture. The conditions are: temperature 60℃, rotation speed 160rpm, volume of liquid in triangular flask 20%, culture time 12h;

[0075] 3. Fermentation in the seed tank, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com