Bismuth titanate based piezoelectric ceramic with high curie temperature and preparation method thereof

A piezoelectric ceramic, bismuth titanate-based technology, applied in the field of high-temperature piezoelectric ceramics, can solve the problems of difficult to obtain dense BIT ceramics, low piezoelectric activity, poor sintering process, etc., and achieve a stable and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

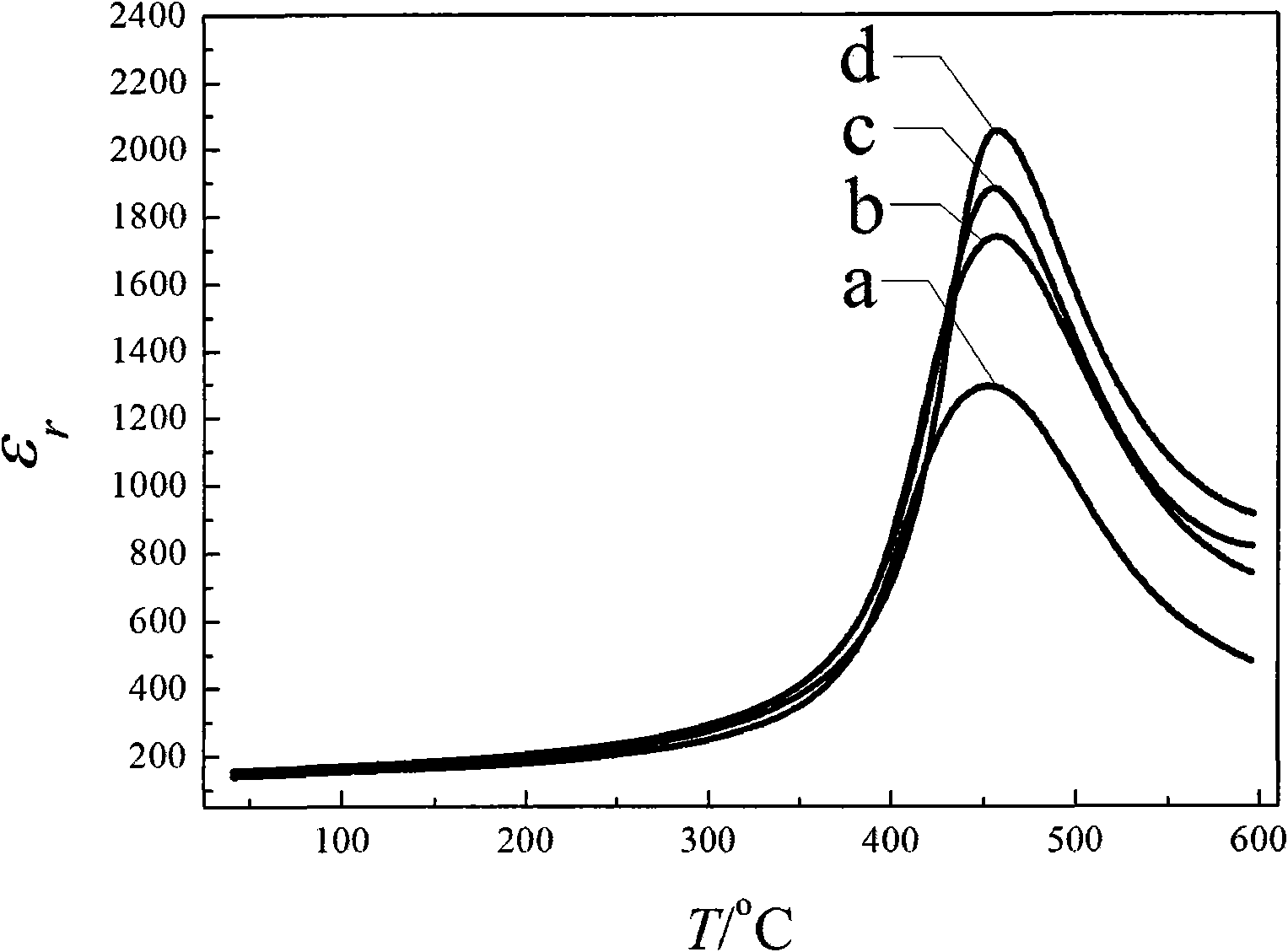

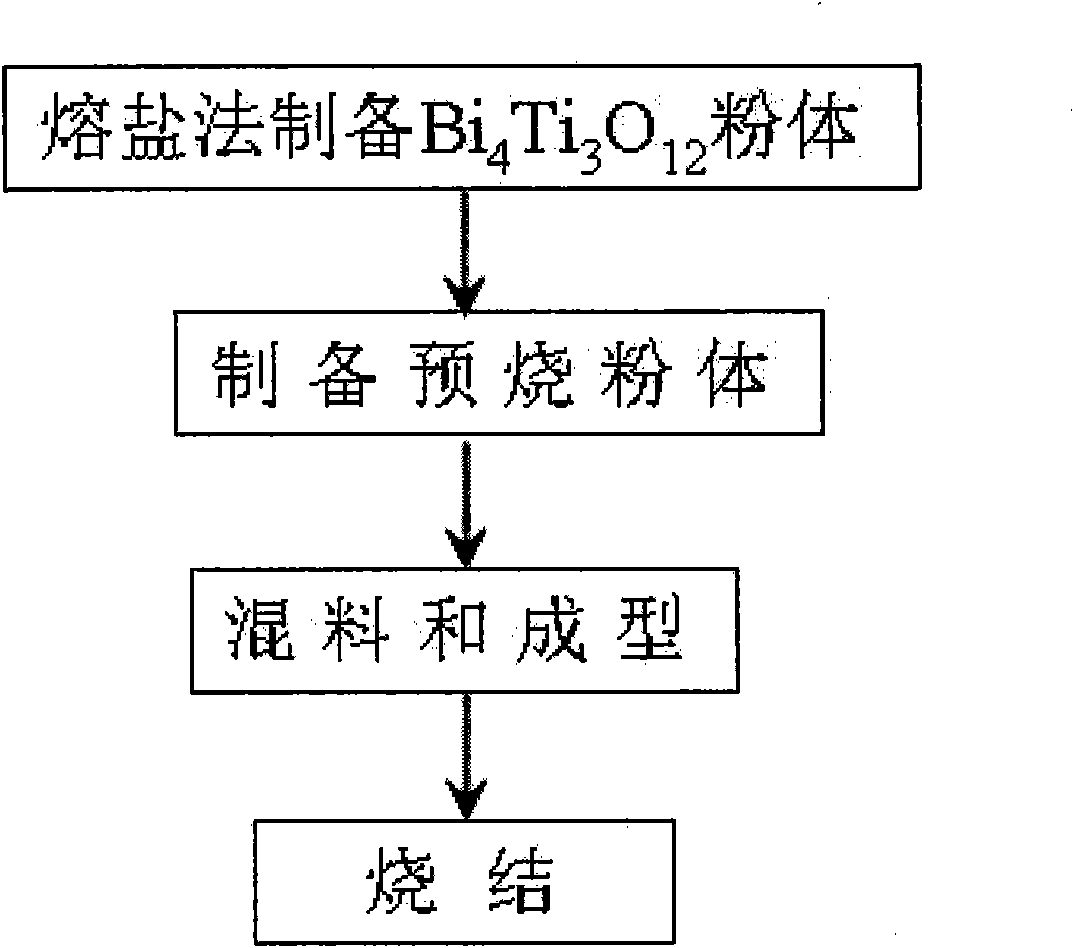

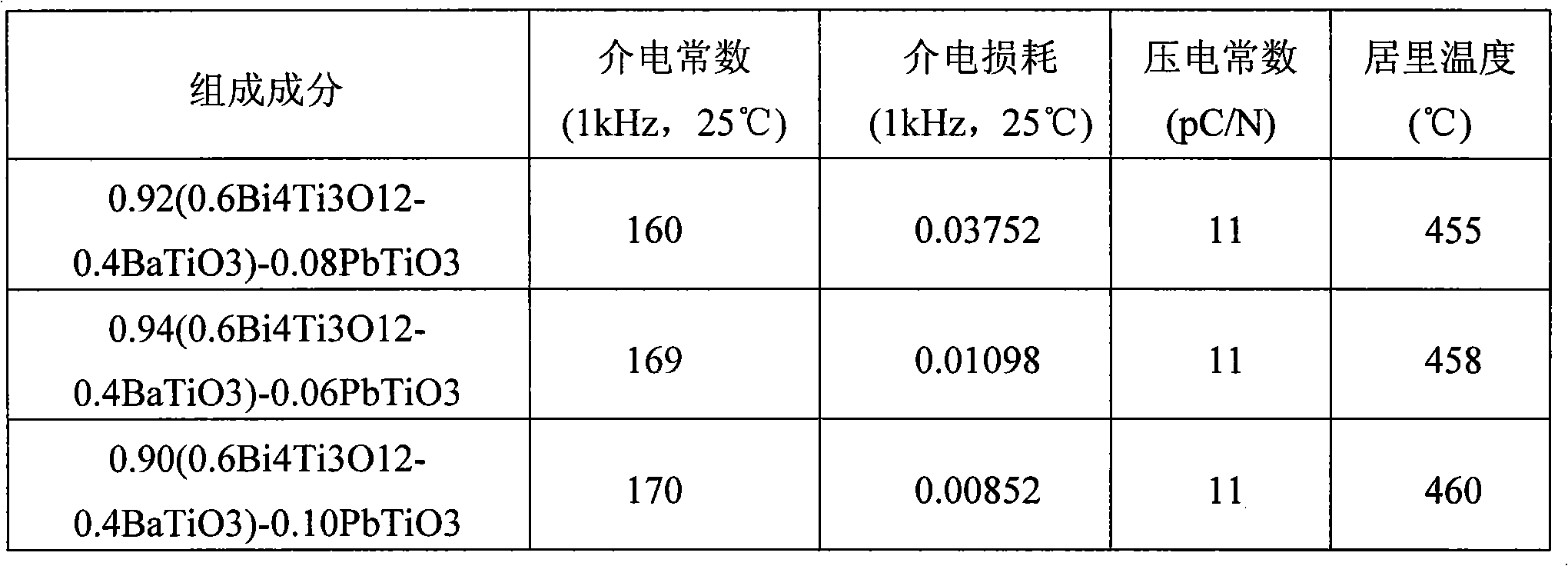

[0024] The present embodiment is a bismuth titanate-based piezoelectric ceramic with a high Curie temperature, and its formula is (1-x)(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-x(1 / 3Pb 3 o 4 +TiO 2 ), wherein, x=0.02, BaTiO 3 , Pb 3 o 4 and TiO 2 for analytical purity. 0.98(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-0.02PbTiO 3 ceramics. Concrete preparation process comprises the following steps:

[0025] Step 1, prepare Bi by molten salt method 4 Ti 3 o 12 Powder; with analytically pure Bi 2 o 3 、TiO 2 as raw material, according to Bi 4 Ti 3 o 12 The stoichiometric ratio ingredients were ball milled in absolute ethanol medium for 24 hours, and after the powder was dried, 25wt% KCl and 25wt% NaCl were added, and then ball milled in anhydrous ethanol medium for 4 hours and then dried at a temperature of 50 ℃; the drying time is 12h, and after drying, pre-burn at 1000°C for 8h to obtain a powder containing molten salt, and the powder is cleaned to verify that there is no Cl...

Embodiment 2

[0031] The present embodiment is a bismuth titanate-based piezoelectric ceramic with a high Curie temperature, and its formula is (1-x)(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-x(1 / 3Pb 3 o 4 +TiO 2 ), wherein, x=0.06, BaTiO 3 , Pb 3 o 4 and TiO 2 for analytical purity. 0.94(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-0.06PbTiO 3 ceramics. Concrete preparation process comprises the following steps:

[0032] Step 1, prepare Bi by molten salt method 4 Ti 3 o 12 Powder; with analytically pure Bi 2 o 3 、TiO 2 as raw material, according to Bi 4 Ti 3 o 12 The stoichiometric ratio ingredients were ball milled in absolute ethanol medium for 24 hours, and after the powder was dried, 25wt% KCl and 25wt% NaCl were added, and then ball milled in anhydrous ethanol medium for 4 hours and then dried at a temperature of 60 ℃; the drying time is 9h, and after drying, pre-calcined at 1000°C for 8h to obtain a powder containing molten salt, and the powder is cleaned to verify that there is no...

Embodiment 3

[0038] The present embodiment is a bismuth titanate-based piezoelectric ceramic with a high Curie temperature, and its formula is (1-x)(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-x(1 / 3Pb 3 o 4 +TiO 2 ), wherein, x=0.10, BaTiO 3 , Pb 3 o 4 and TiO 2 for analytical purity. 0.90(0.6Bi 4 Ti 3 o 12 -0.4BaTiO 3 )-0.10PbTiO 3 ceramics. Concrete preparation process comprises the following steps:

[0039] Step 1, prepare Bi by molten salt method 4 Ti 3 o 12 Powder; with analytically pure Bi 2 o 3 、TiO 2 as raw material, according to Bi 4 Ti 3 o 12 The stoichiometric ratio ingredients were ball milled in anhydrous ethanol medium for 24 hours, and 25wt% KCl and 25wt% NaCl were added after the powder was dried, and then dried in anhydrous ethanol medium for 4 hours after ball milling at a temperature of 70 ℃; the drying time is 6h, and after drying, pre-burn at 1000°C for 8h to obtain a powder containing molten salt, and the powder is cleaned to verify that there is no Cl -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com