Device and method for processing elongated holes with high cleanliness and low roughness

A technology of low roughness and processing equipment, which is applied in metal processing equipment, manufacturing tools, and machine tools designed for grinding the rotating surface of workpieces. The effect of meeting the processing requirements of high cleanliness and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

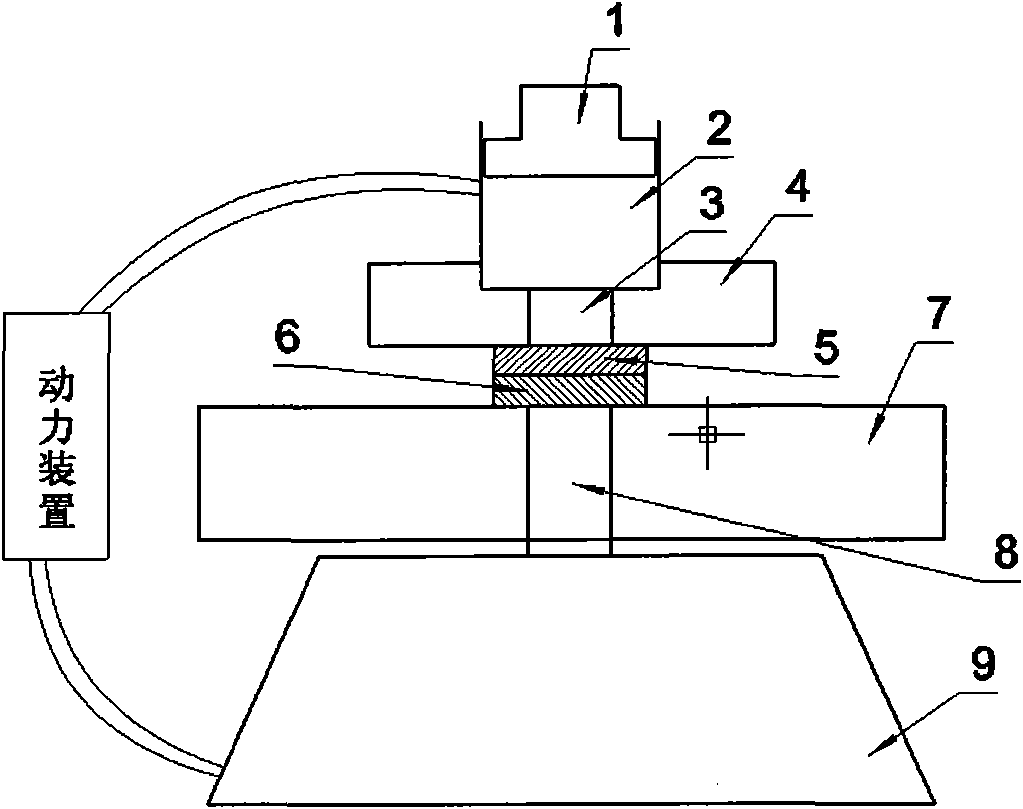

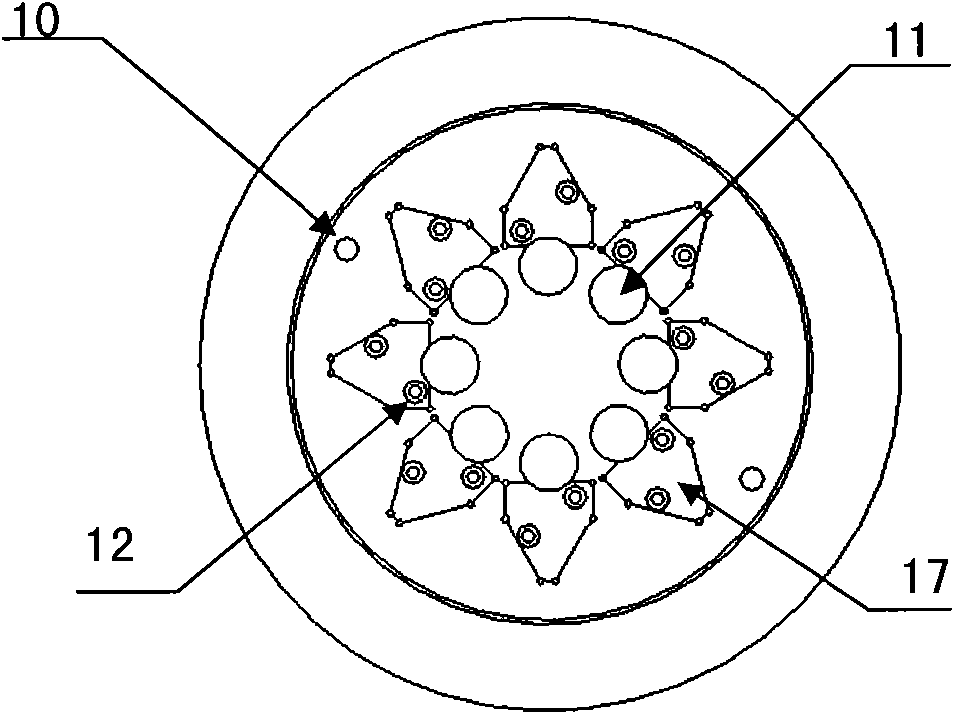

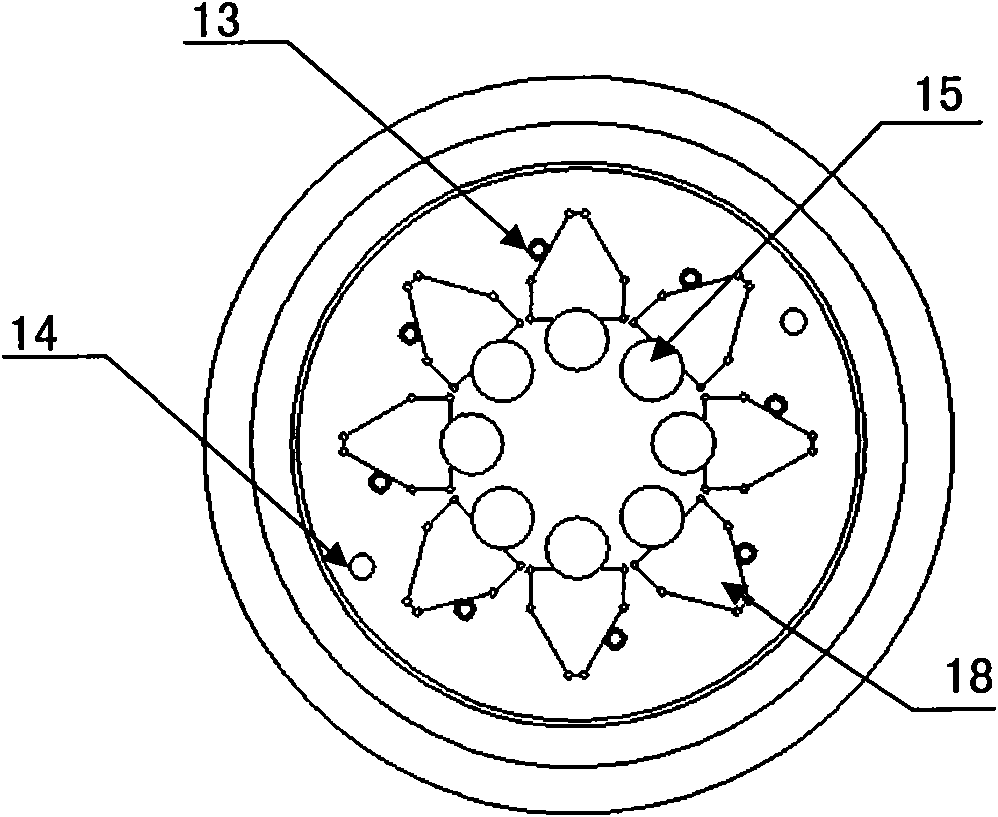

[0018] A high-cleanliness and low-roughness elongated hole system processing device, including a piston 1, an abrasive pressure cylinder 2, a feed port 3, a pressure table 4, an upper die 5, a lower die 6, a workbench 7, and a return port 8, The material box 9 and the power device are characterized in that: the upper mold 5 has 2 positioning holes 10, n discharge grooves 11, n tooling feeding holes 12 and n workpiece grooves 17; the lower mold 6 has 2 pins Holes 14, n discharge grooves 15, n tooling return holes 13 and n workpiece grooves 18; through positioning pins 16, 2 positioning holes of the upper mold and 2 pin holes of the lower mold, the upper and lower molds are connected and fixed Form an integral mold, and n workpieces are packed in the cavity formed by the upper mold workpiece groove 17 and the lower mold workpiece groove 18; into the range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com