Surface acoustic wave device

一种声表面波、波长的技术,应用在阻抗网络、压电器件/电致伸缩器件、用于压电器件或电致伸缩器件的材料选择等方向,能够解决声表面波装置电机械耦合系数增大、基板的欧拉角范围狭小等问题,达到大电机械耦合系数、反射系数大、提高特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, the present invention will be clarified by describing specific embodiments of the present invention with reference to the drawings.

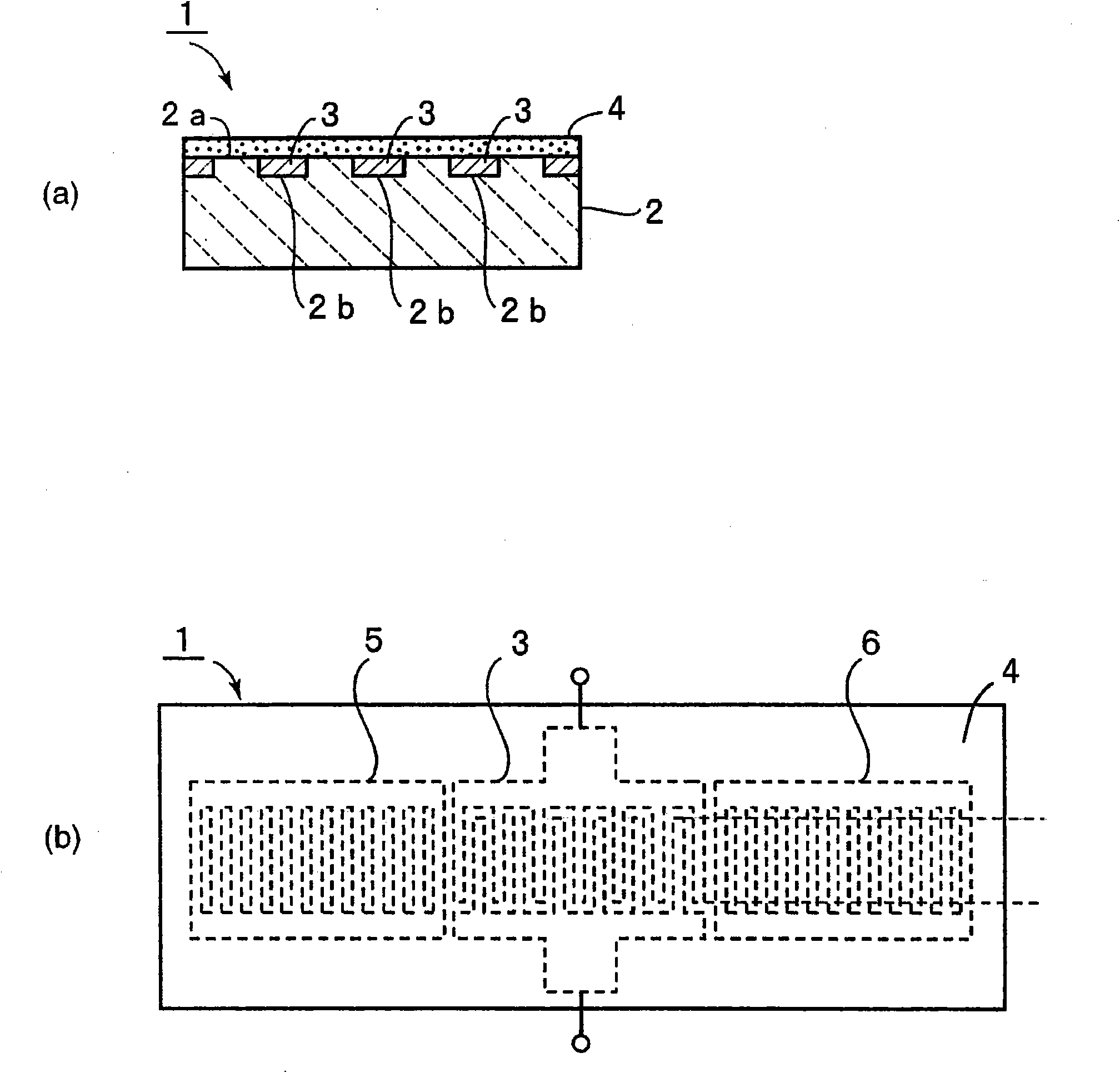

[0075] figure 1 (a) and (b) are schematic partial front cross-sectional views of portions forming the IDT of the surface acoustic wave device according to the first embodiment of the present invention, and (b) is a schematic plan view of the surface acoustic wave device.

[0076] like figure 1 As shown in (a), the surface acoustic wave device 1 has LiNbO 3 Substrate 2. In LiNbO 3 A plurality of grooves 2b are formed on the upper surface 2a of the substrate 2 . The IDT 3 having a plurality of electrode fingers is formed by filling the plurality of grooves 2b with metal. The upper surface of the IDT 3 and the LiNbO 3The upper surface 2a of the substrate 2 becomes one surface.

[0077] SiO is formed to cover the upper surface 2a and the IDT 3 2 film4. In addition, in the present invention, it is not necessary to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com