Method and device for sterilizing/washing cap

A cleaning device and cleaning medium technology, applied in packaging sterilization, bottle cap pretreatment, chemistry, etc., can solve problems such as poor cleaning efficiency, save space and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

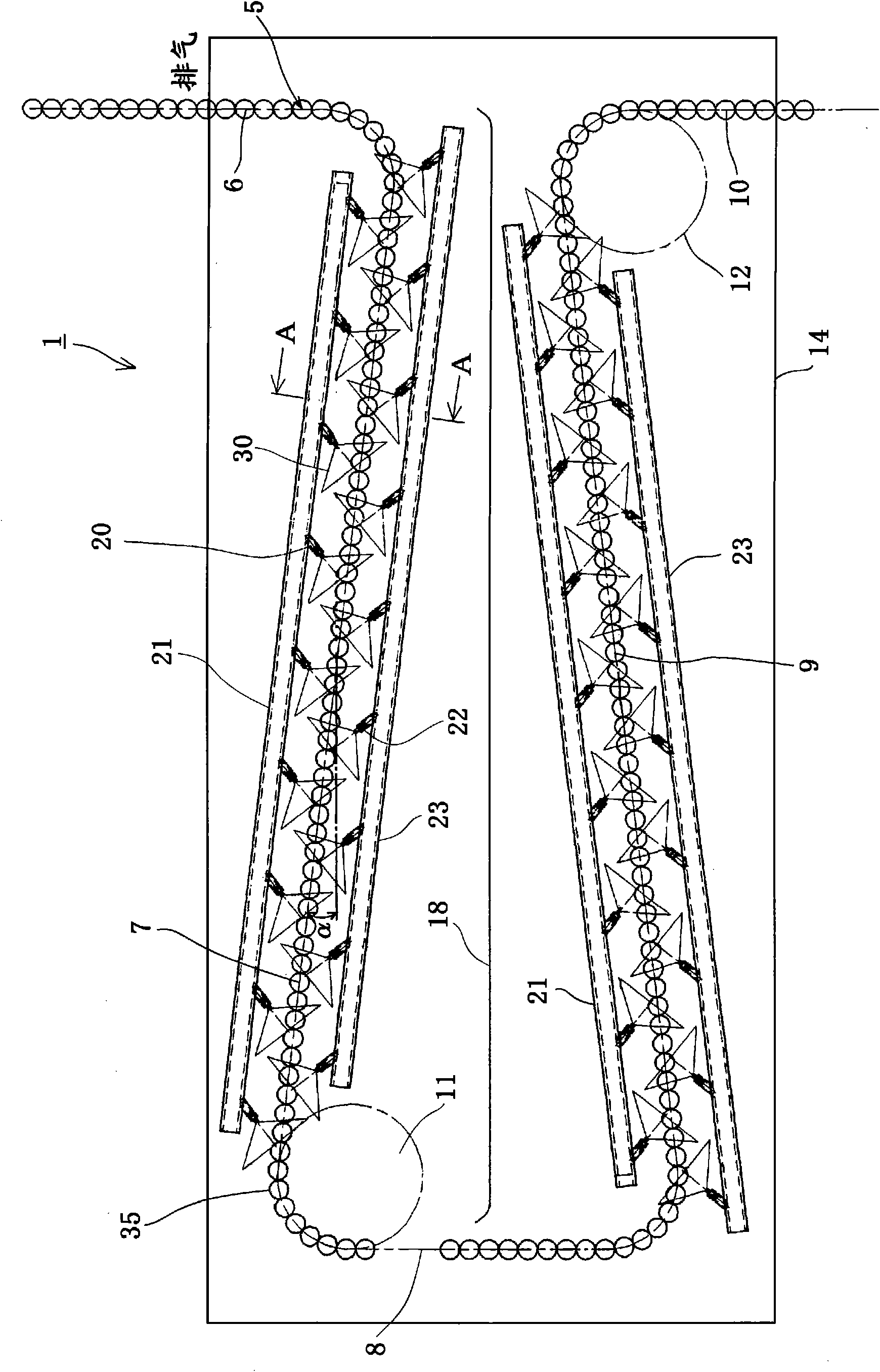

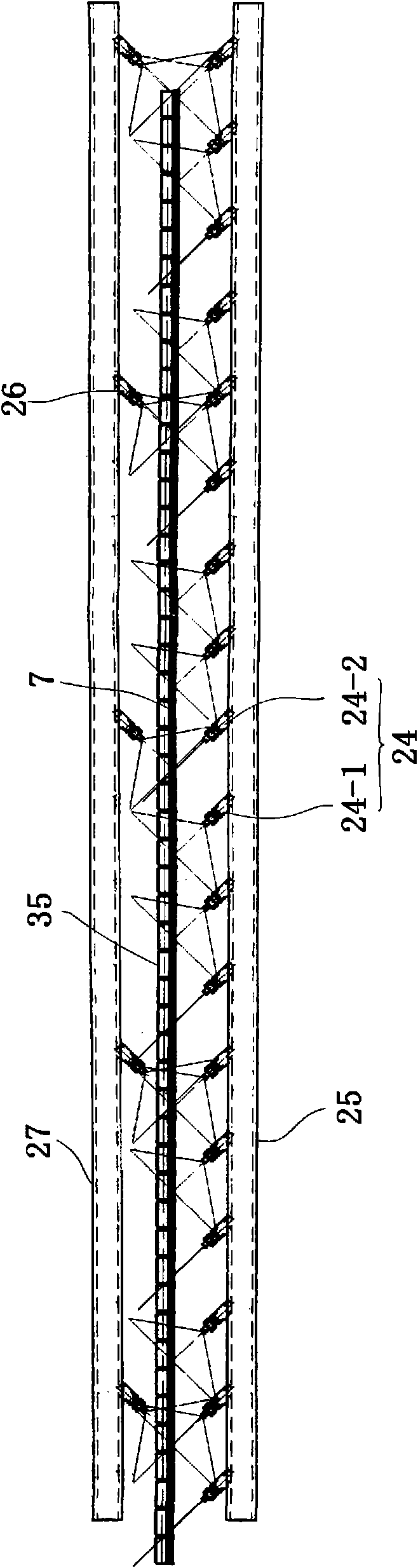

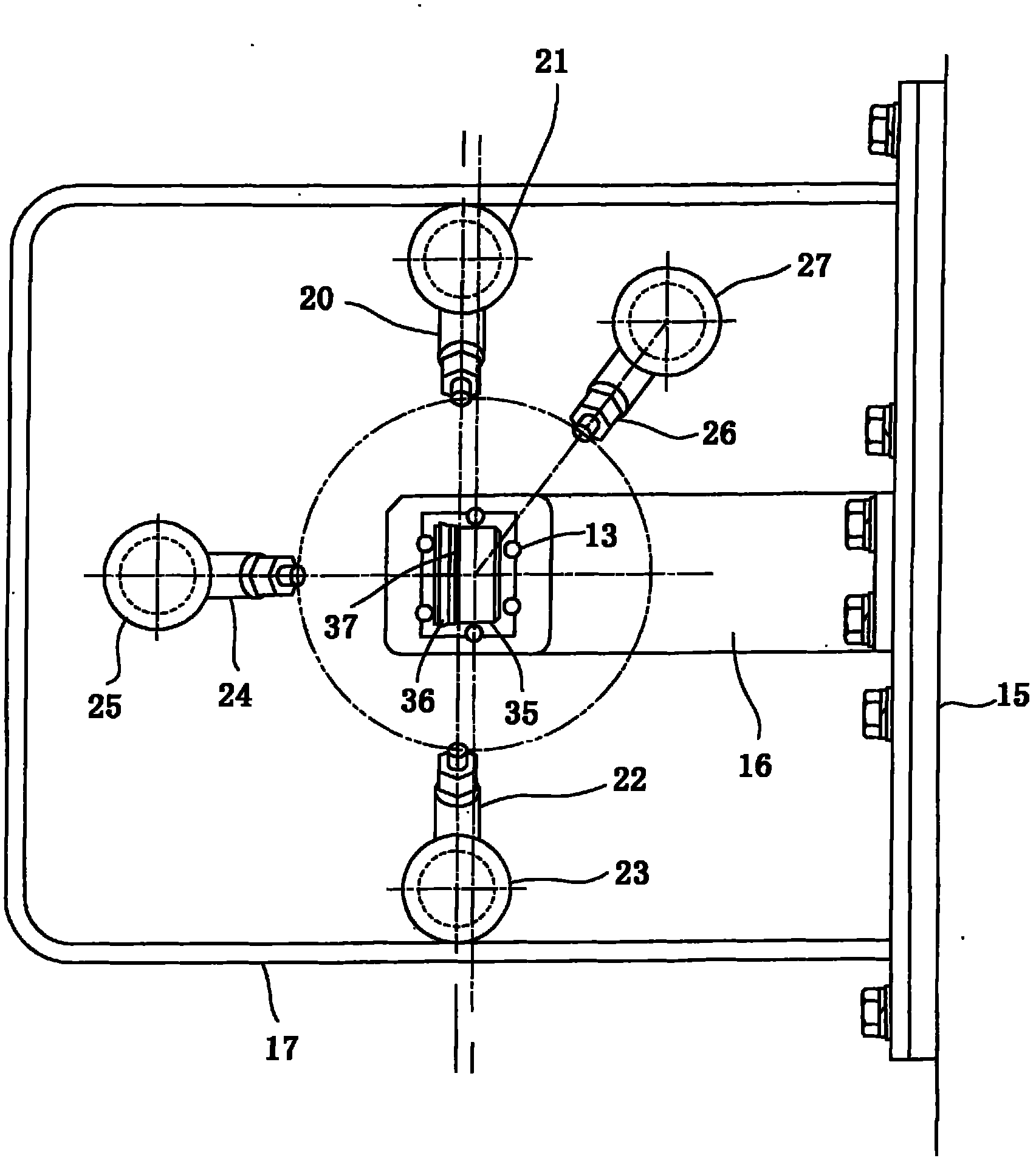

Embodiment 1

[0045] Set the inclination angle of the rising inclined groove part to 7° to form a groove, and surround the groove with Figure 4 In the arrangement form shown, hot water pipes A to D are arranged. These hot water pipes A, B, C, and D are formed so that a maximum of 14 nozzles can be arranged over the entire length based on a pitch of 100 mm (the length of the nozzle section is 1400 mm), and each part is arranged from the upstream in the state shown in Table 1. Configure jet nozzles. Among them, in the table, F represents a fan nozzle (spray angle 110°), S represents a straight nozzle (spray angle 0°), and P represents a plug (that is, there is no nozzle but a closed state). Such as Figure 5 As shown, each of the above-mentioned nozzles is arranged at an inclination of 45° relative to the conveying direction. in addition, Figure 4 In a1, b1, c1, d1 represent the linear distance from the outer periphery of each hot water pipe to the nearest linear guide of the groove, an...

Embodiment 2

[0054] As Example 2, such as Figure 6 As shown, all spray nozzles of the hot water pipe A are arranged at right angles to the conveying direction. In this case, the total number of spray nozzles having an inclination angle of 90° is seven, accounting for about 21% of the total number of 33 spray nozzles. In this case, the injection pressure of the hot water sprayed from the injection nozzles arranged in the hot water pipe A at right angles to the conveyance direction acts on the caps, which becomes conveyance resistance, and creates a distance between the caps being conveyed. As a result, the shielding portion that hot water cannot touch disappears, hot water can effectively contact the entire circumference of the cover, and the cleaning effect is further improved compared to the case of Example 1. Therefore, the orientation of the nozzles is not limited to the case where all the nozzles are arranged obliquely with respect to the conveying direction of the caps. By providin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com