Rectangular etching ion gun

An ion gun and rectangular technology, applied in the field of rectangular etching ion guns, can solve the problems of inability to etch devices with large aspect ratios, shortened cathode filament life, poor ion beam uniformity, etc., and achieves lower temperature and faster etching speed. , The effect of ion beam uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

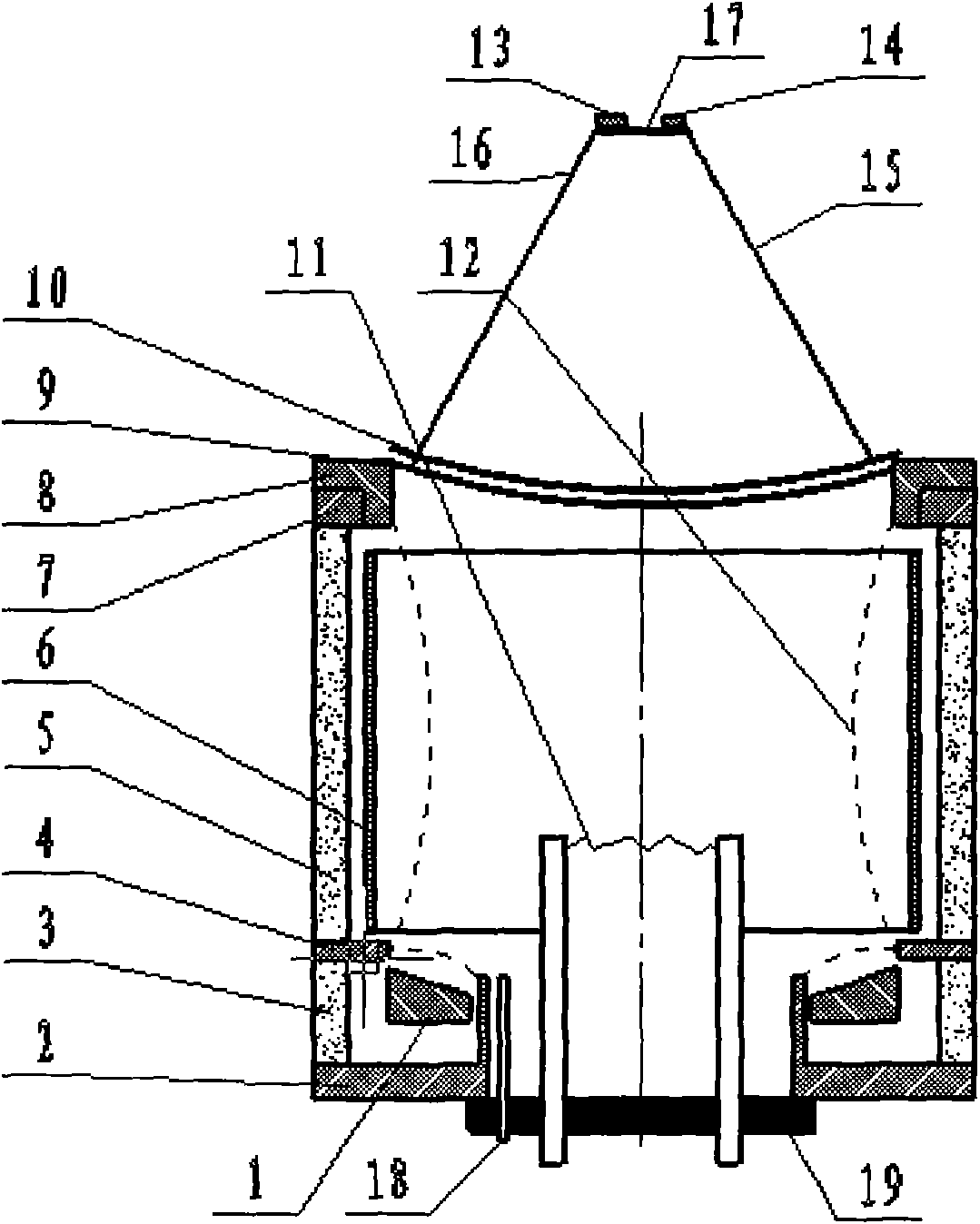

[0077] Such as figure 1 As shown, the first pole piece 2, the first magnet 3, the second pole piece 4, the second magnet 5, the third pole piece 7 and the fourth pole piece 8 in this embodiment constitute a rectangular shape. overall;

[0078] The first pole shoe 2 is an annular rectangular plate with a rectangular tube in the center of the upper surface, and the external dimensions of the annular rectangular plate are: 90mm (width)*150mm (length)*5mm (thickness), with a single side width of 25mm ; The size of the rectangular tube is: 40mm (width) * 110mm (length) * 20mm (height), the wall thickness of the rectangular tube is 2mm;

[0079] The second pole shoe 4 is a ring-shaped rectangular plate, and its external dimensions are: 90mm (width)*150 (length)*2mm (thickness), with a single side width of 10mm

[0080] The third pole shoe 7 is a ring-shaped rectangular plate, and its external dimensions are: 90mm (width)*150mm (length)*5mm (thickness), and the width of one side i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com