Double-liquid capillary micro-flow control valve in micro-flow control chip, and manufacturing method thereof

A technology of a microfluidic chip and a manufacturing method, which are applied in the photoengraving process, valve device, instrument and other directions of the pattern surface, can solve the problem of difficulty in achieving high affinity for liquid while injecting the liquid residue, increasing the complexity of the process and the difficulty of processing, High liquid affinity is easy to fail, etc., to achieve the effects of cheap structural materials, improved reliability, and guaranteed simultaneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

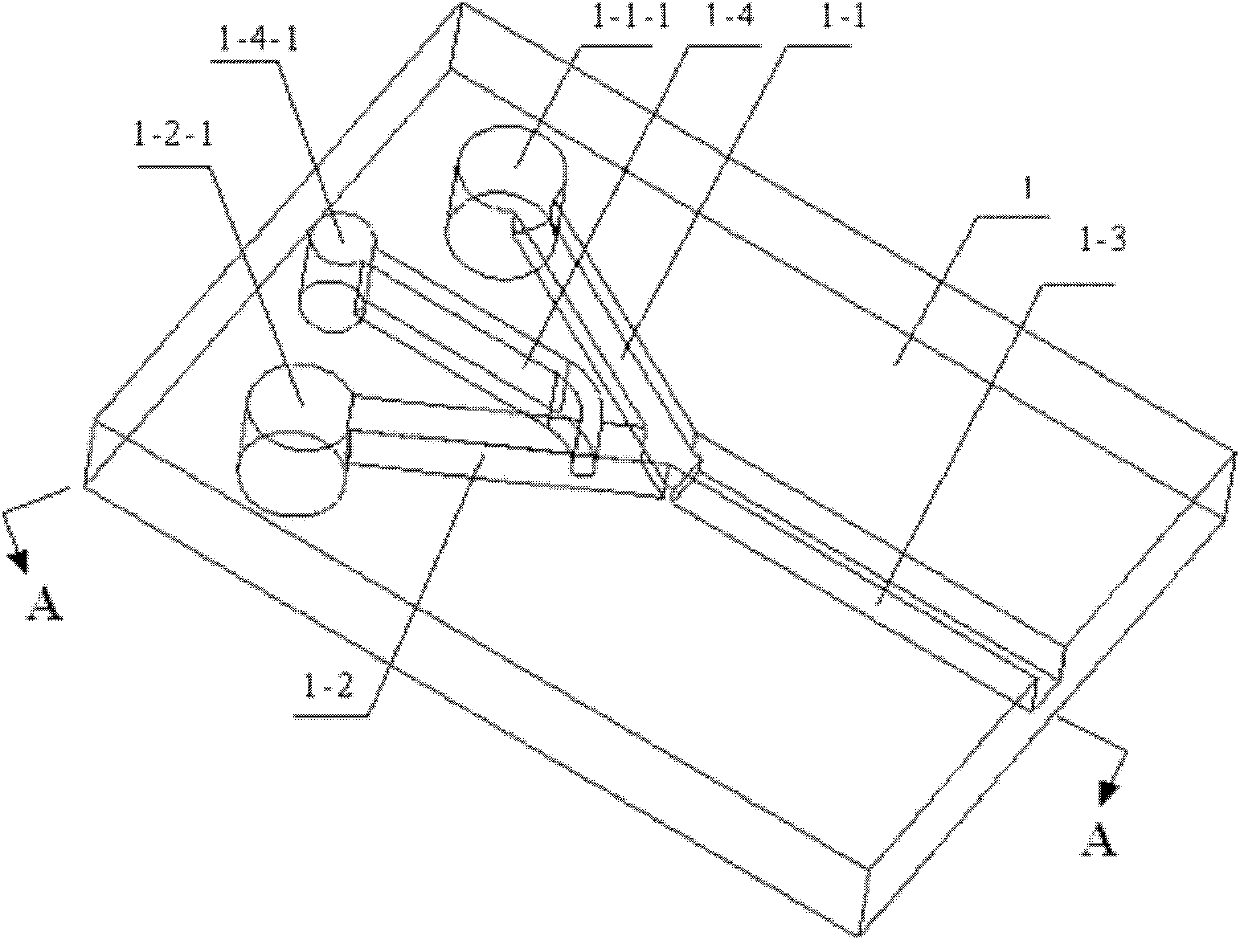

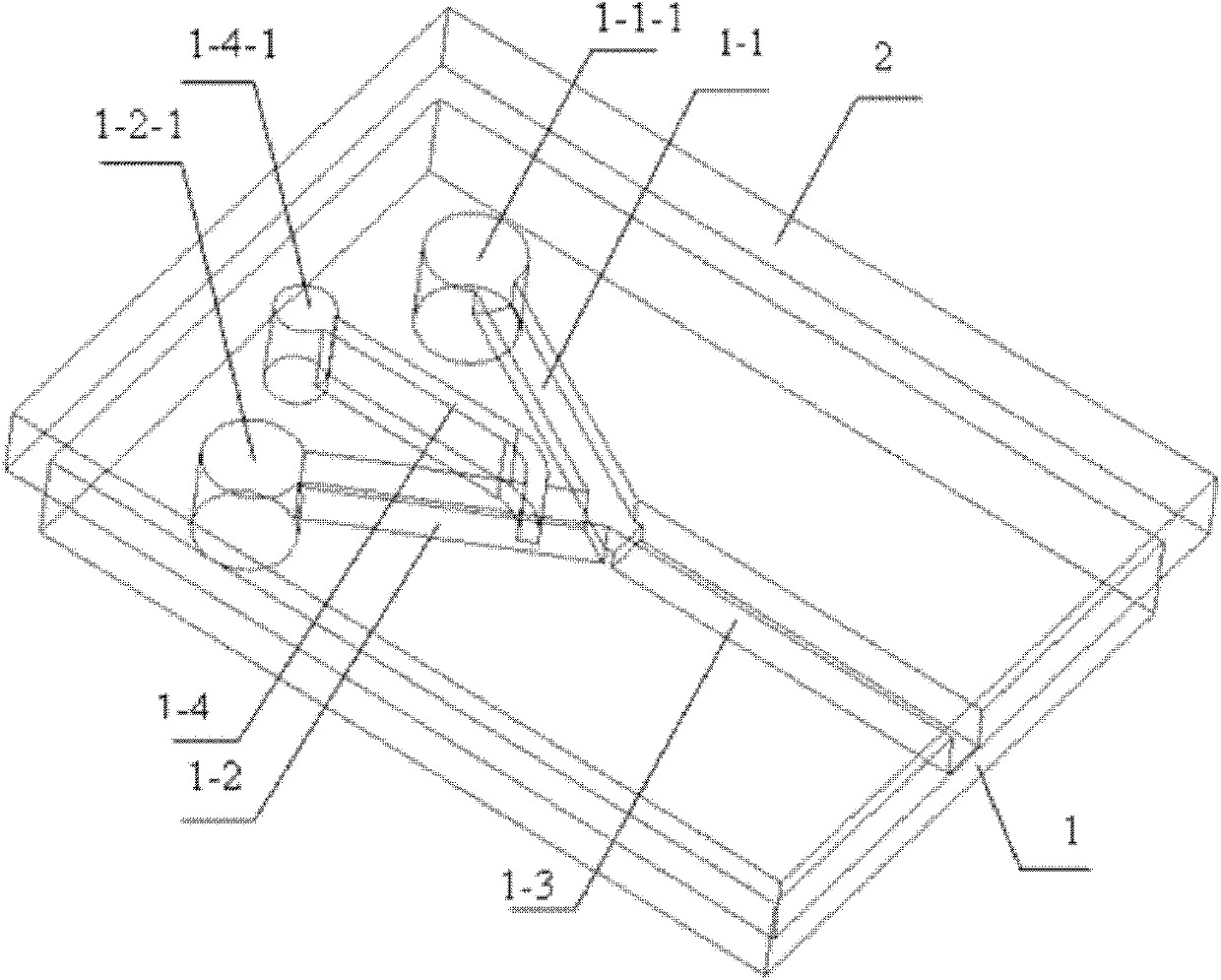

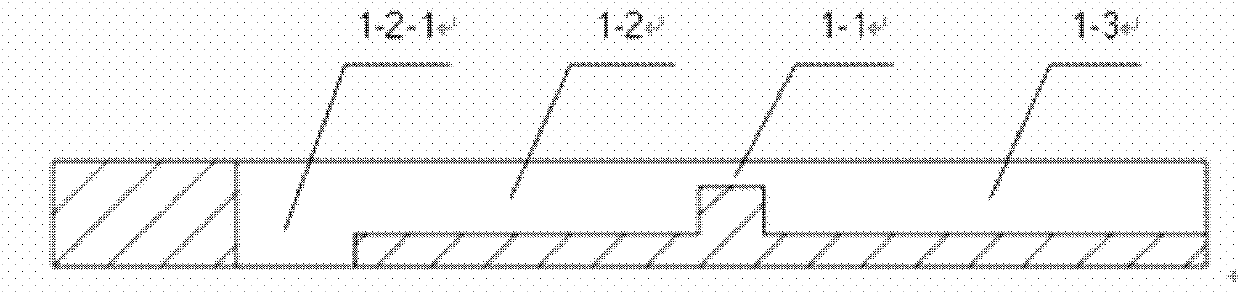

[0023] Specific implementation mode 1. Combination Figure 1 to Figure 3 To illustrate this embodiment, the dual-liquid capillary micro-flow control valve in the microfluidic chip is a Y-shaped capillary channel formed by placing the PDMS substrate 1 with grooves on the surface on the surface of the glass sheet 2. The grooves on the surface of the sheet 1 include a first tributary groove 1-1, a second tributary groove 1-2, an output groove 1-3 and an airway groove 1-4; the first tributary groove 1-1 1. The cross-sectional width of the second tributary groove 1-2 and the output groove 1-3 is equal; the cross-sectional width of the air channel groove 1-4 is smaller than the first tributary groove 1-1, the second tributary groove 1-2 and the cross-sectional width of the output groove 1-3; the depth of the second tributary groove 1-2 and the output groove 1-3 are equal, and the depth of the first tributary groove 1-1 is smaller than the second tributary groove The depth of the gr...

specific Embodiment approach 2

[0026] Embodiment 2. This embodiment is a method for manufacturing the dual-liquid capillary microfluidic control valve in the microfluidic chip described in Embodiment 1. The specific steps of the method are:

[0027] Step 1. Spin-coat photoresist on the surface of the oxidized Si single wafer, and photoetch the first tributary groove 1-1, the second tributary groove 1-2, the output groove 1-3 and the air channel The photoresist pattern of the grooves 1-4, and then wet-etch SiO after the photoresist pattern is hardened 2 , and then remove the photoresist of the first tributary groove 1-1, the second tributary groove 1-2, the output groove 1-3 and the remaining part of the airway groove 1-4 to obtain the first tributary groove 1- 1. SiO of the second tributary groove 1-2, the output groove 1-3 and the airway groove 1-4 channel 2 mask pattern;

[0028] Step 2, the SiO obtained in step 1 2Evaporate a 1 μm thick aluminum film on the mask pattern, then spin-coat photoresist on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com