Plate type ice storage trough

An ice storage tank, plate technology, applied in the heating method, fixed plate conduit assembly, application and other directions, can solve the problems of occupying building space and air-conditioning water channel blockage, etc., to achieve easy heat exchange enhancement, uniform ice thickness, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

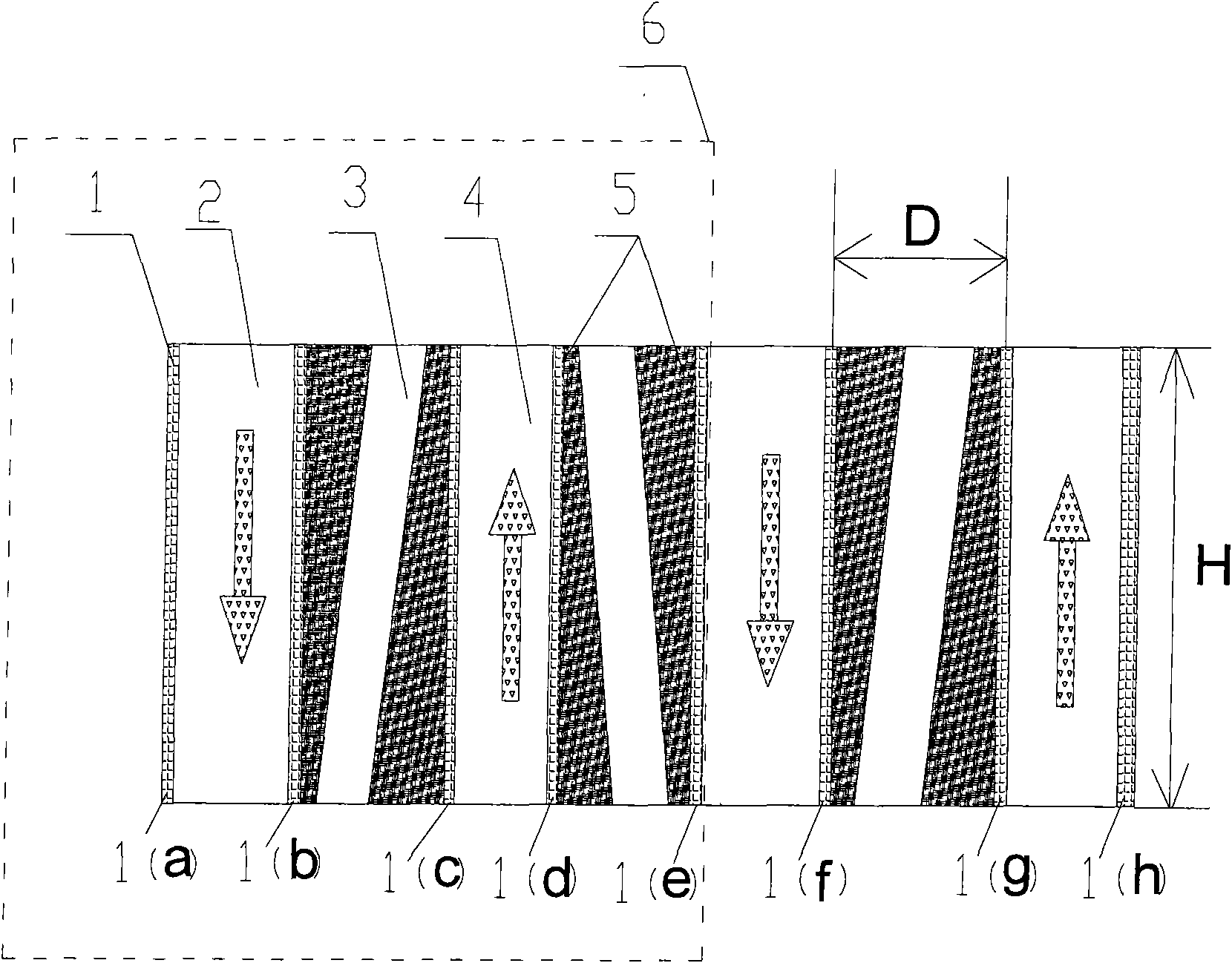

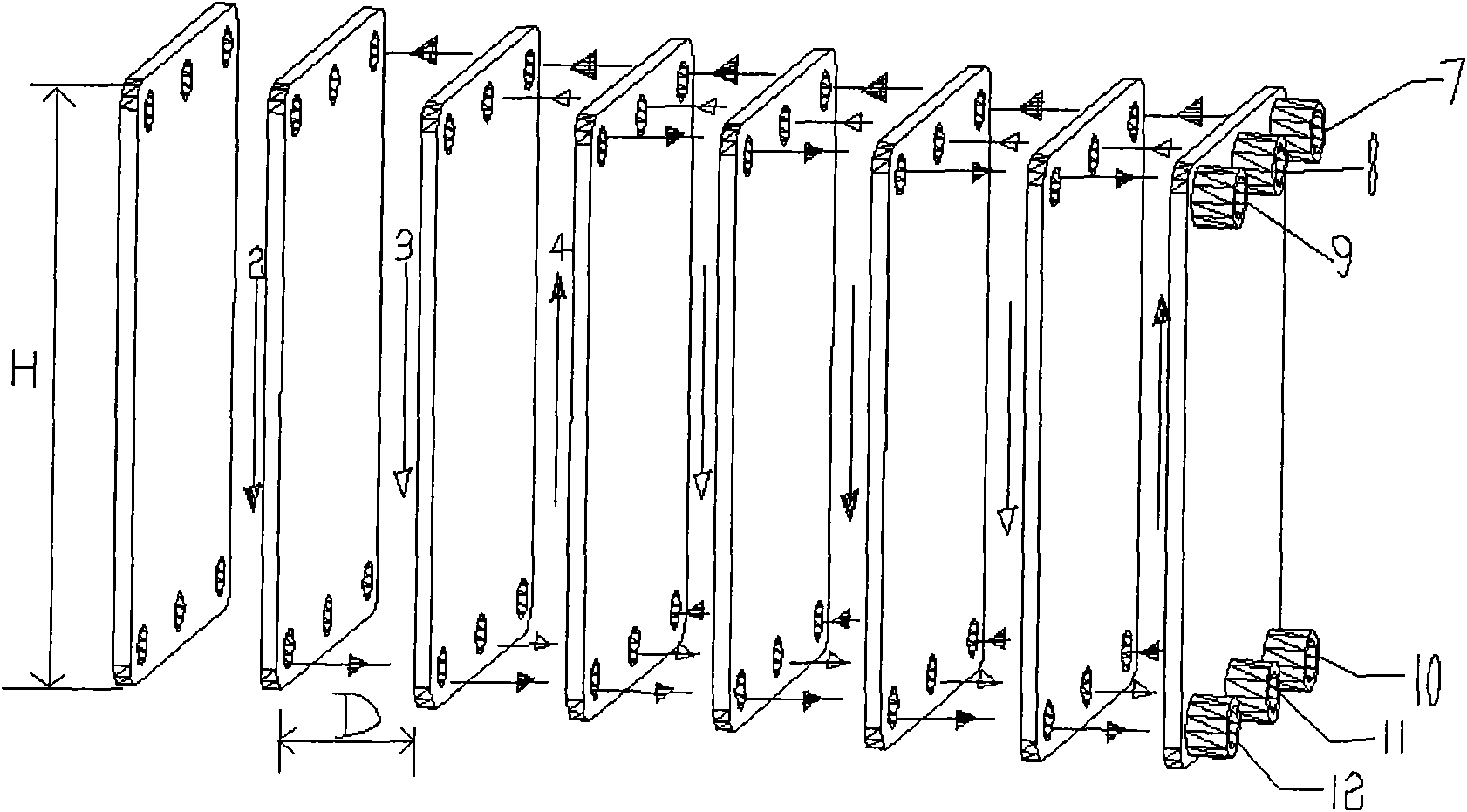

[0021] figure 1 is a sectional view of the first embodiment of the present invention when storing ice, figure 2 is a schematic flow diagram of the first embodiment of the present invention. In this embodiment, the direction of the plate-type ice storage tank heat exchange plate is perpendicular to the ground. The plate ice storage tank includes a set of heat exchange plates 1(a), 1(b), 1(c), 1(d), 1(f), 1(g) and 1(h). An air-conditioning water ice storage channel 3 is formed between the heat exchange plates 1(b) and 1(c), 1(d) and 1(e), and 1(f) and 1(g). A low-temperature fluid channel 2 is formed between the heat exchange plates 1(a) and 1(b), 1(e) and 1(f), and the flow direction of the low-temperature fluid in the low-temperature fluid channel 2 is upward. A low-temperature fluid channel 4 is formed between the heat exchange plates 1(c) and 1(d), 1(g) and 1(h), and the flow direction of the low-temperature fluid in the low-temperature fluid channel 4 is downward. The ...

Embodiment approach 2

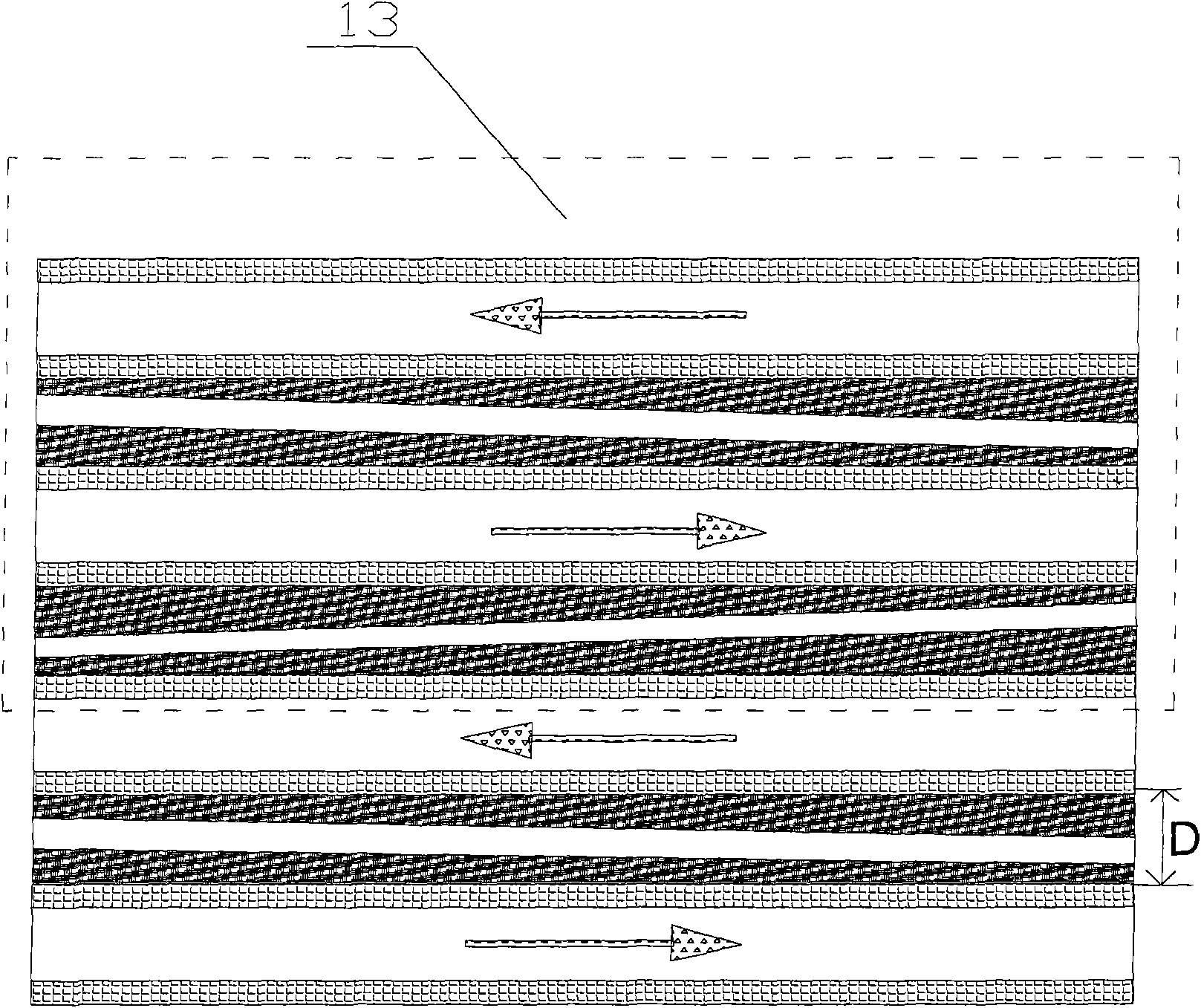

[0025] image 3 It is a sectional view of another embodiment of the present invention during ice storage. In this embodiment, the direction of the heat exchange plate is parallel to the ground. In this embodiment, the flow directions of the cryogenic fluid and the air-conditioning water are both along the horizontal direction. The ice storage method is the same as when the heat exchange plate is placed vertically, so it will not be repeated here. The distance between the heat exchange plates of the air-conditioning water ice storage channel, the distance D shown is 40mm-120mm. The plate ice storage tank can be composed of many heat exchange plates, and the most basic structural unit is the basic structure 13 shown in the figure.

[0026] The material of the heat exchange plate of the plate type ice storage tank is any one of stainless steel plate or heat conducting plastic plate.

[0027] The heat exchange plate of the above-mentioned plate ice storage tank is any one of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com