Miniature power unit

A power unit and micro technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of unclean pipeline, troublesome maintenance, valve stuck, etc., to achieve low power consumption, convenient maintenance, start-up Low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

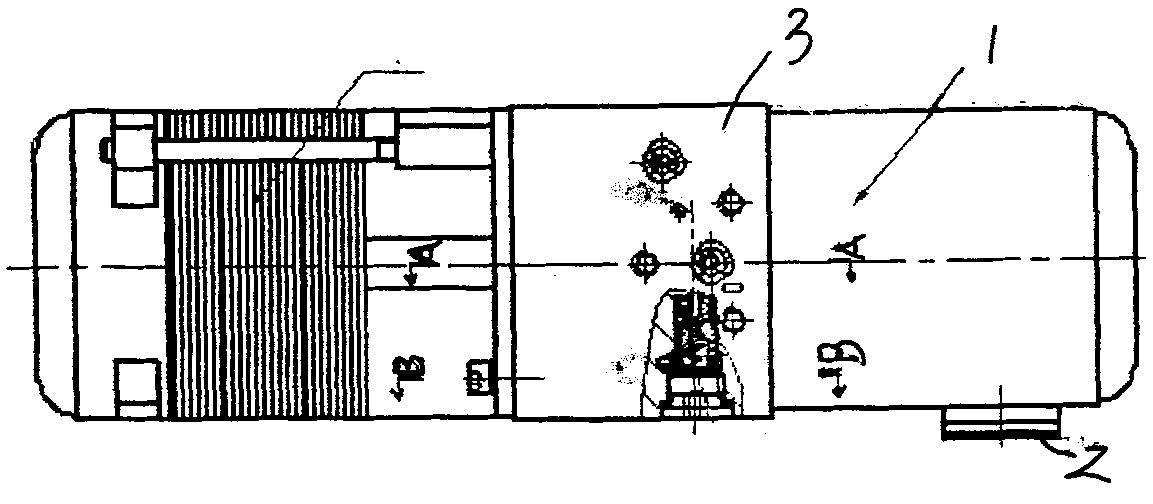

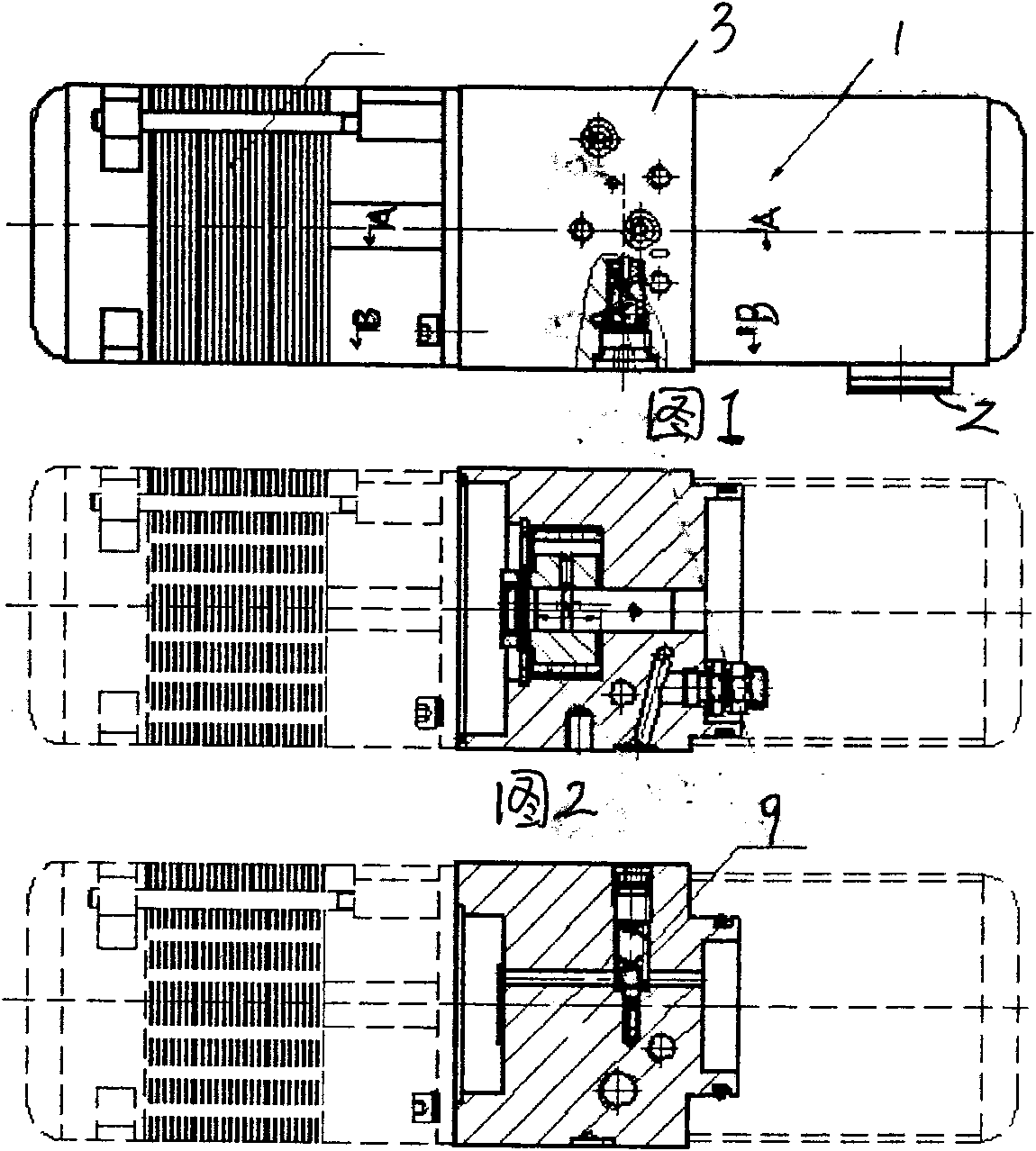

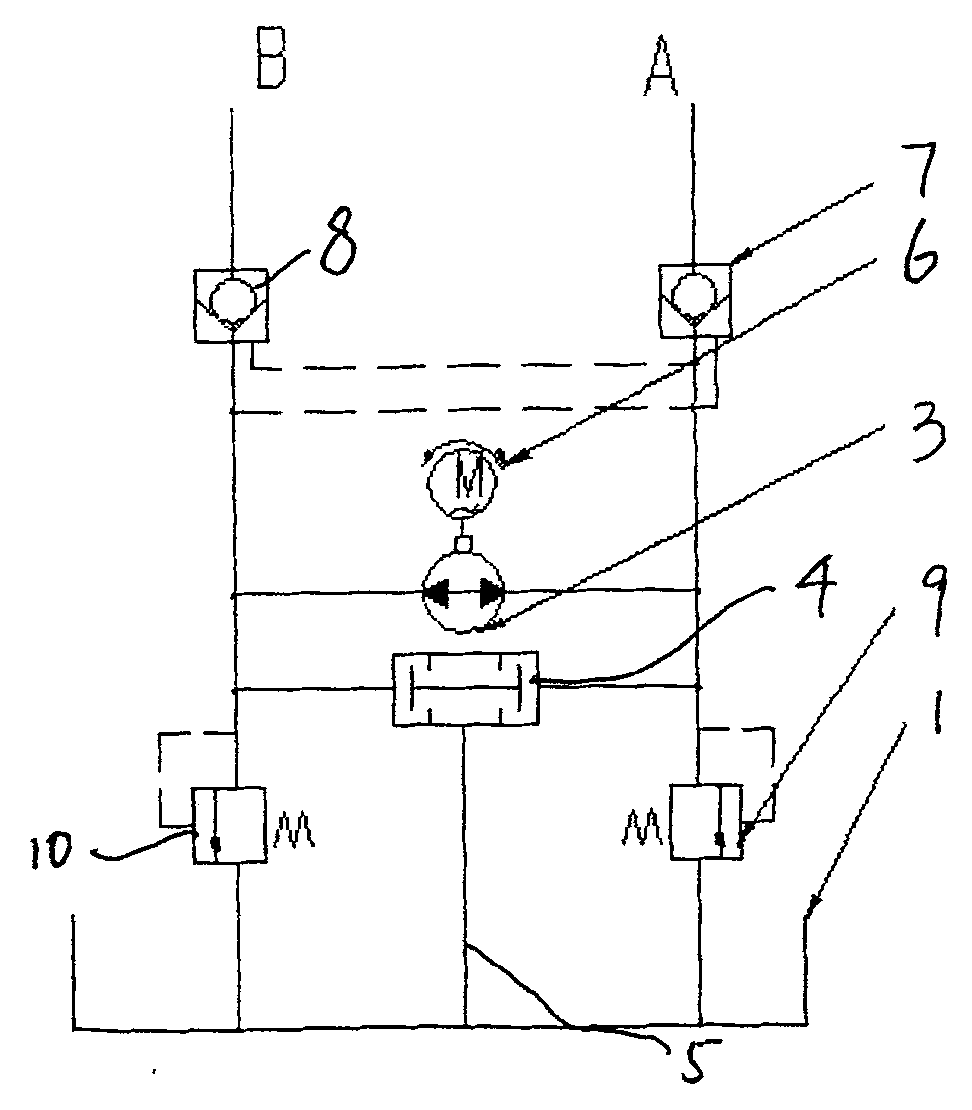

[0014] A miniature power unit, including a fuel tank 1 with an oil filling port 2, a shuttle valve 4 controlled by a double-acting plunger pump 3 connected to an oil pipe 5 extending into the fuel tank, and the double-acting plunger pump 3 is connected to a device that controls its work The motor 6 is connected, and the two ends of the shuttle valve are respectively connected with the oil holes A and B of the two ends of the hydraulic actuator through the check valves 7 and 8; the oil tank, double-acting plunger pump and motor are assembled in an integrated form, and the double-acting plunger The pump is located in the middle, and the oil tank and motor are located on both sides of the double-acting plunger pump. Both ends of the shuttle valve communicate with the fuel tank 1 through safety valves 9 and 10 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com