Six-eccentric bidirectional sealing butterfly valve

A two-way sealing and eccentric technology, which is applied in the direction of shaft sealing, valve lift, valve details, etc., can solve the problems of large reverse leakage, unstable reverse sealing performance, increased valve cost, etc., achieve small opening and closing torque, and solve the problem of Unstable reverse sealing performance and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

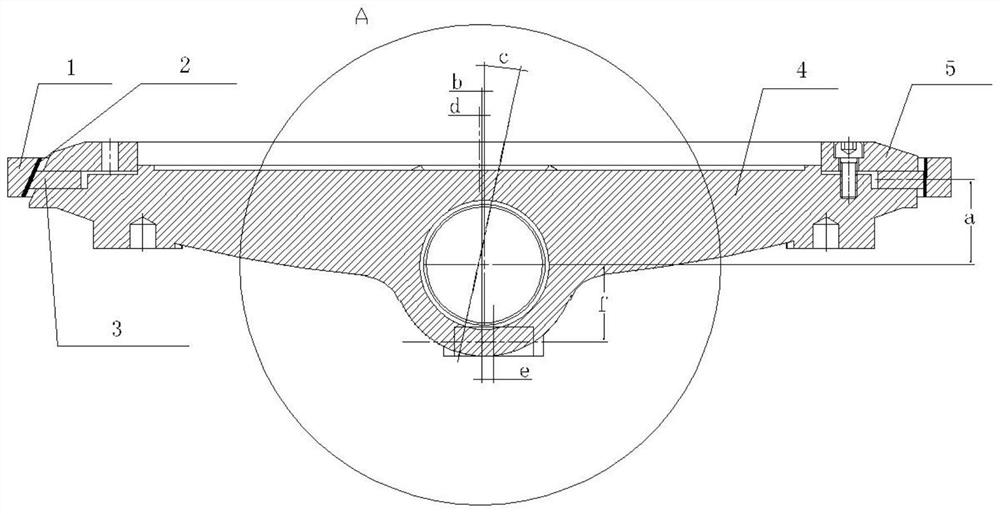

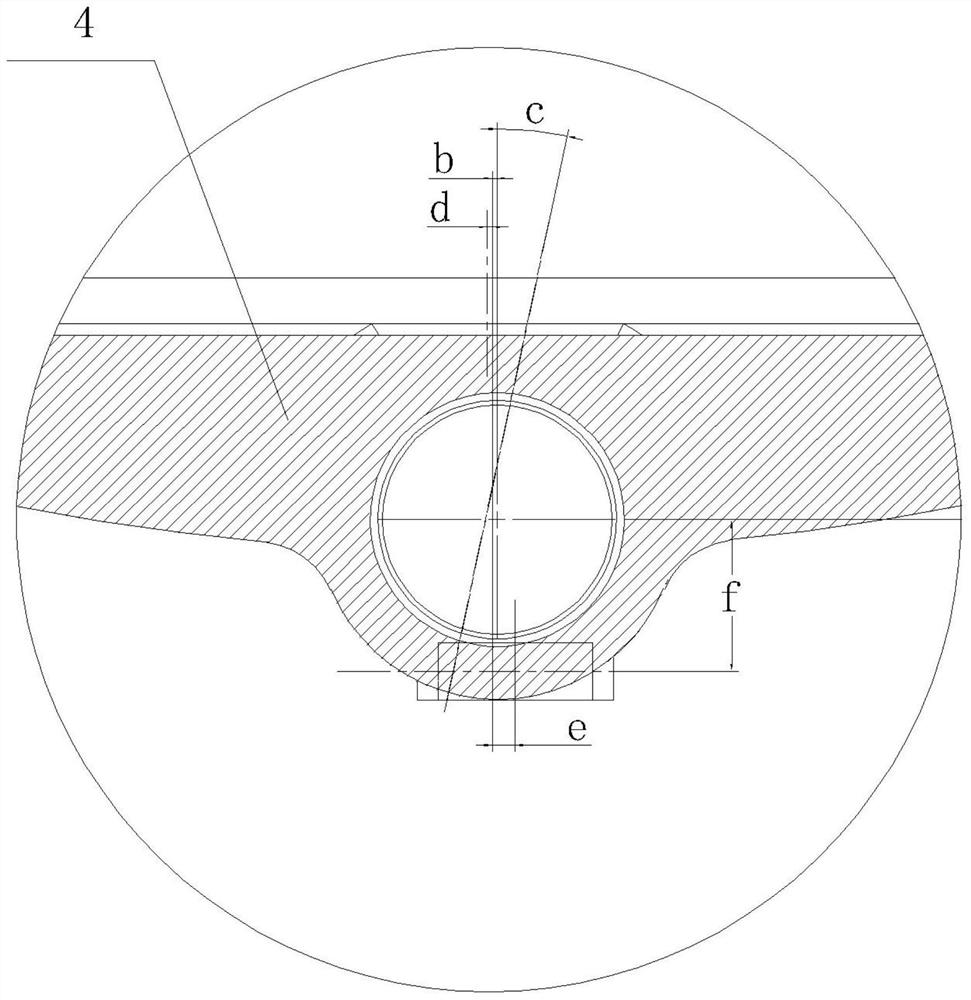

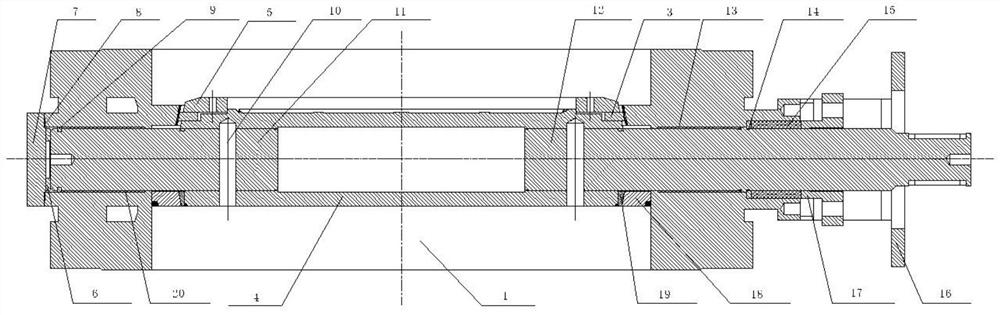

[0023] Such as Figure 1-5 A six-eccentric two-way sealed butterfly valve shown includes a valve body 1, a butterfly plate 4, a valve stem, a main valve seat 2, an auxiliary valve seat 18, a main sealing ring 3, a compression ring 5 and an auxiliary sealing ring 19. The plate 4 is located in the valve body 1, the valve stem is fixedly connected with the butterfly plate 4, the two ends of the valve stem are rotatably matched with the valve body 1, and the main valve seat 2 and the auxiliary valve seat 18 are located on both sides of the valve stem , one side of the butterfly plate 4 is provided with an annular concave platform, the main sealing ring 3 is arranged in the annular concave platform, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com