Roll gap positioning mechanism of front pinch roll

A positioning mechanism and pinch roller technology, which is applied in the field of metal strip recoiling inspection unit equipment, can solve the problems of strip scratches, tape heads are difficult to pass through the pinch roller at the beginning, and tension is unstable, so as to avoid scratches and increase Large opening, easy to wear the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

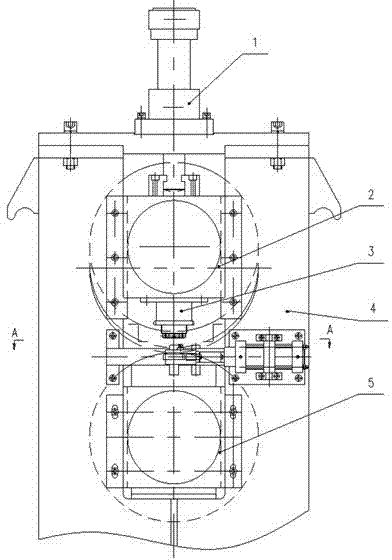

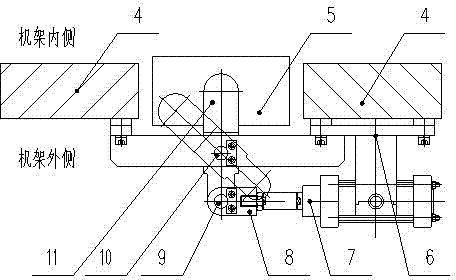

[0012] Such as figure 1 and figure 2 As shown, a first pinch roller gap positioning mechanism is characterized in that it comprises a bracket 6, an air cylinder 7, a joint 8, a movable pin shaft 9, a connecting rod 11, and a fixed pin shaft 10. The positioning mechanism is located on the upper and lower clamps. Between the bearing housings of the steering roller, and installed on the outside of the frame 4 by bolt connection, the cylinder 7 is installed on the bracket 6, one end of the joint 8 is threaded with the cylinder 7, and the other end is connected with the active end of the connecting rod 11 through a movable pin The shaft 9 is connected. The intermediate position of the connecting rod 11 is connected with the bracket 6 through the fixed pin shaft 10. When the piston rod of the cylinder 7 extends, the driven end of the connecting rod 11 is located at the center of the upper surface of the lower pinch steering roller bearing seat, and the connecting rod 11 can swing ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com