Condensation heat recovery central heating system of power plant indirect air cooling machine set

An air-cooled unit, central heating technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve the problems of unavailability of exhaust heat, affecting the overall efficiency of energy utilization, and generating thermal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

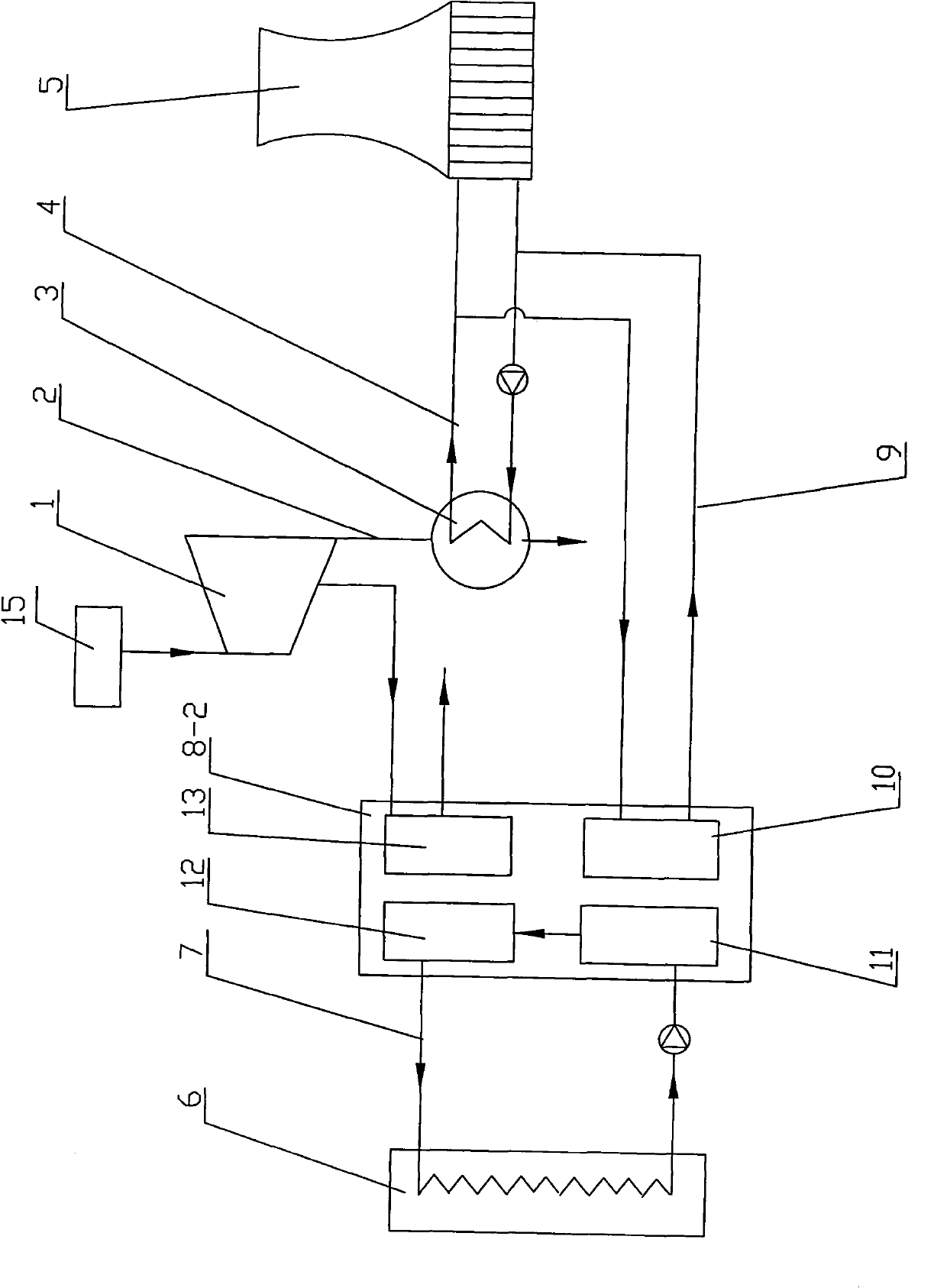

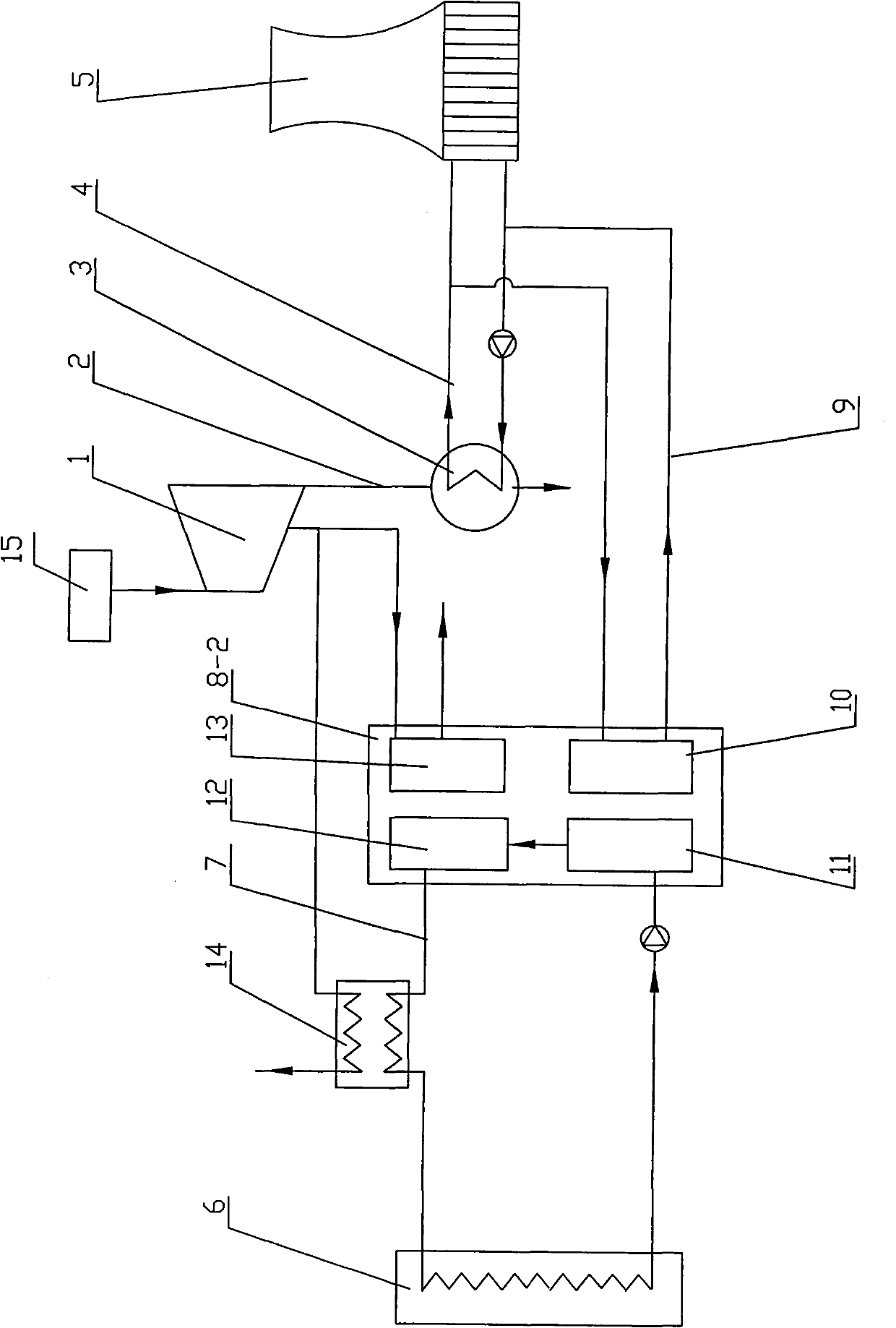

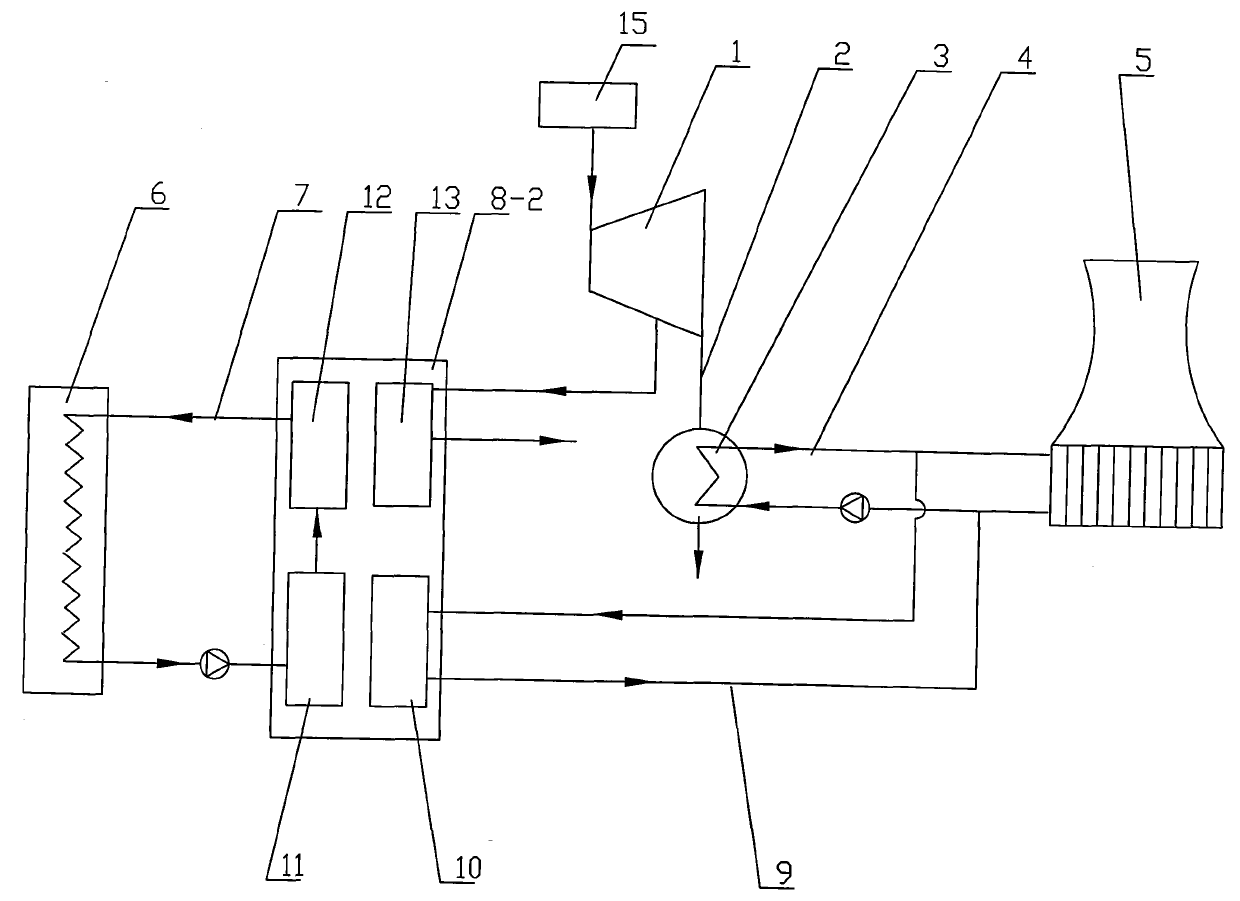

[0017] Option One:

[0018] Such as figure 2 Shown is a schematic diagram of the central heating system for recovering condensation heat of the indirect air-cooling unit of the power plant according to the present invention. Depend on figure 1 It can be seen that the central heating system for recovering condensation heat of the indirect air-cooled unit of the power plant of the present invention consists of a steam turbine 1, a steam turbine exhaust main pipe 2, a water-cooled condenser 3, a closed cooling circulating water system 4, and an indirect air-cooled steam system 5. The heating place 6, the hot water supply pipeline system 7, the absorption heat pump unit 8-2, the residual hot water circulation pipeline system 9 and related connecting pipeline valves and control systems (not shown in the figure) etc. constitute. The absorption heat pump unit 8 - 2 includes an evaporator 10 , an absorber 11 , a condenser 12 and a generator 13 . The exhaust steam of the steam turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com