Combined heat and power system for directly recovering exhaust afterheat of power station steam turbine by absorption heat pump

An absorption heat pump and combined heat and power technology, which is applied in steam engine installations, steam applications, mechanical equipment, etc., can solve the problems of increasing investment in water pump power consumption of waste hot water systems, improve comprehensive energy utilization efficiency, and eliminate heat exchange temperature. Loss, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

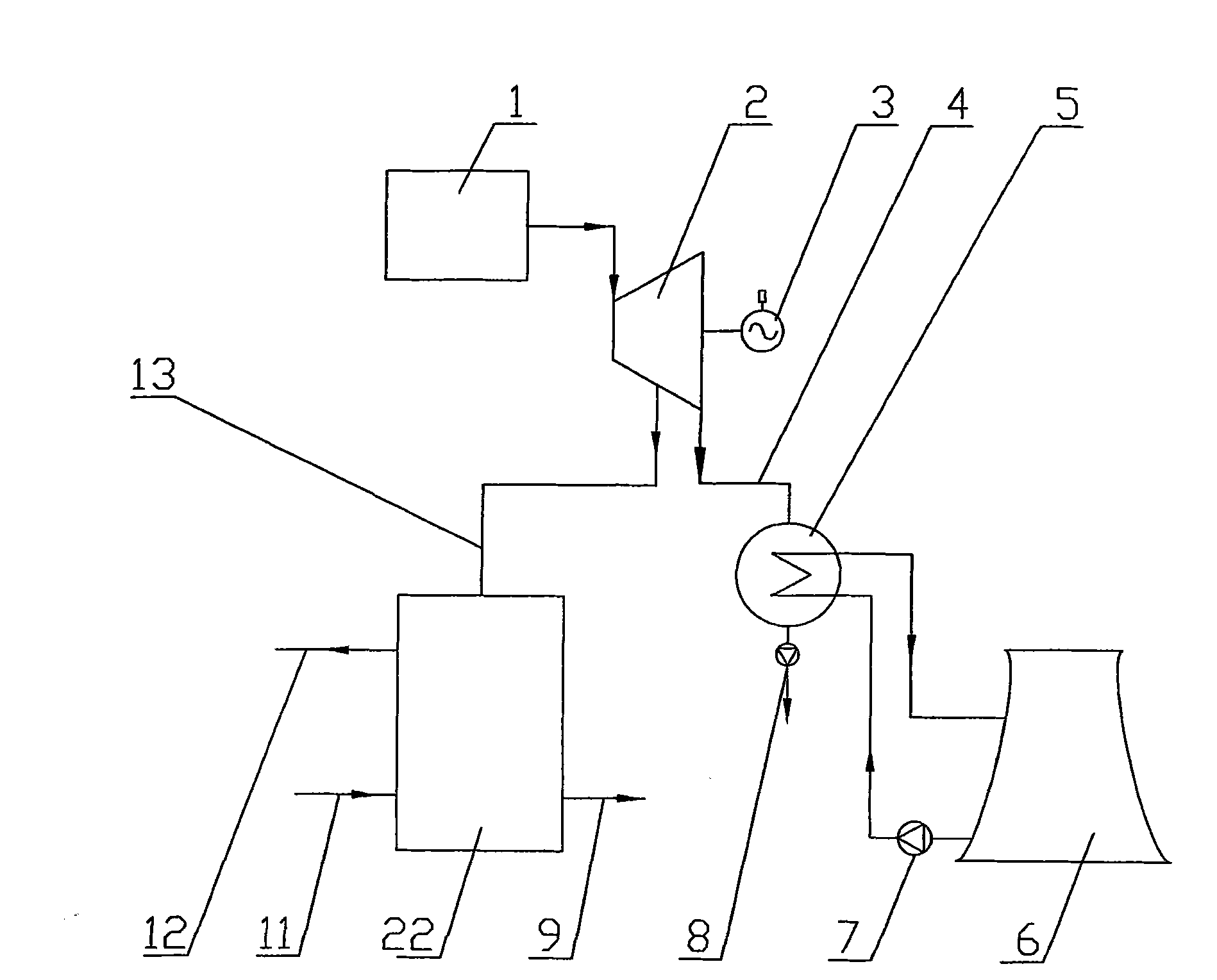

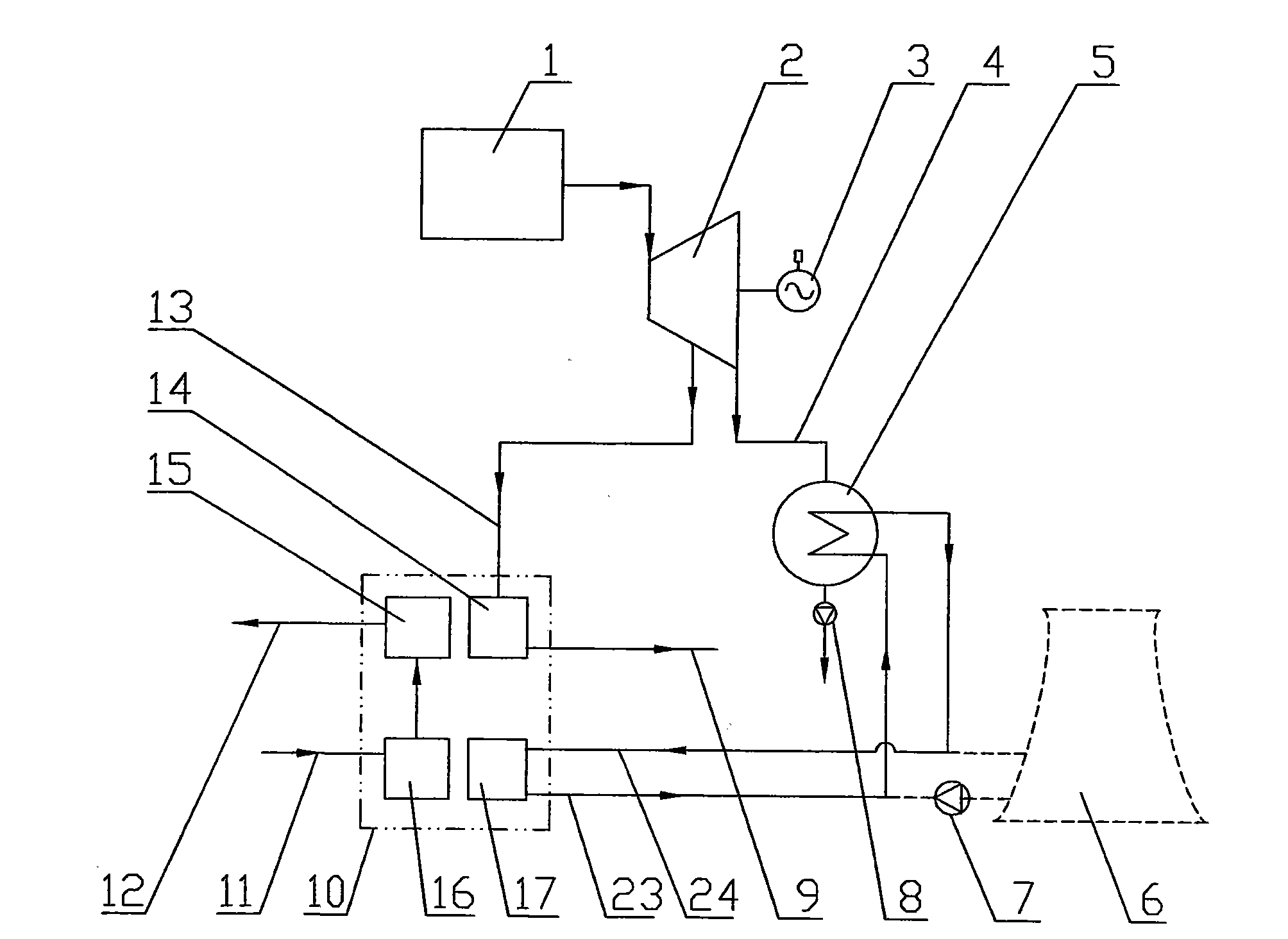

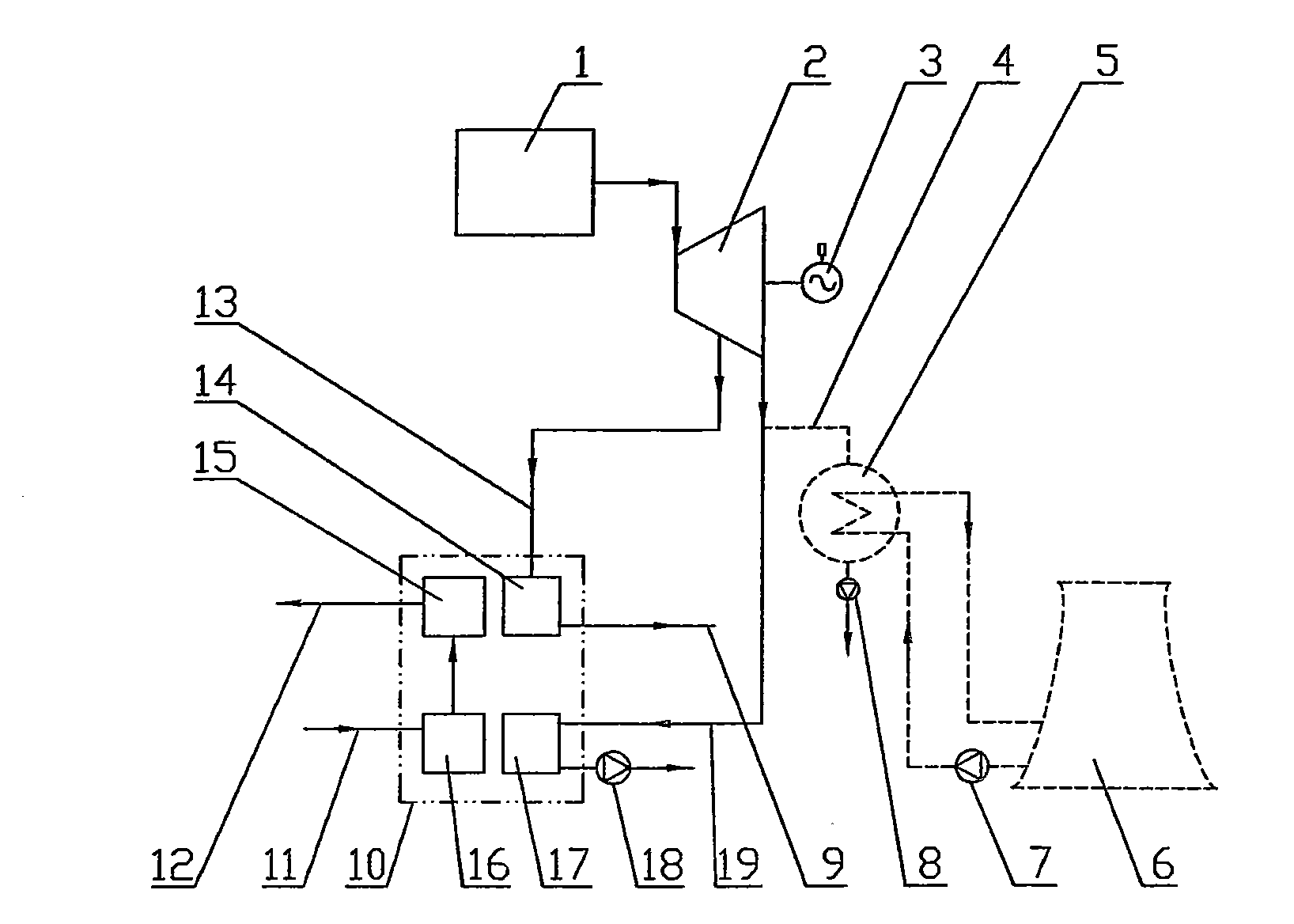

[0013] Such as image 3 Shown is a schematic diagram of a combined heat and power system that uses circulating water to cool the exhaust steam of the steam turbine and uses an absorption heat pump to directly recover the waste heat from the exhaust steam of the power station turbine. Power plant boiler 1, steam turbine 2, generator 3, steam turbine exhaust pipe 4, condenser 5, cooling tower (or air cooling system) 6, circulating water pump 7, exhaust condensate pump 8, steam extraction condensate return boiler pipe 9 , absorption heat pump 10, hot water return pipe 11, hot water outlet pipe 12, steam turbine extraction pipe 13, exhaust condensed water outlet evaporator pump 18 and steam turbine exhaust steam inlet evaporator pipe 19 and control system (not shown in the figure output) and other components of the absorption heat pump to directly recover the steam turbine exhaust heat cogeneration system of the power station. The absorption heat pump 10 is composed of a generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com