Cement fly ash foaming composite heat insulation material

A technology of composite thermal insulation material and cement fly ash, applied in thermal insulation, building components, applications, etc., can solve problems such as water seepage construction, easy cracking, falling off, etc., and achieve the effects of ensuring construction quality, saving energy, and solving construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

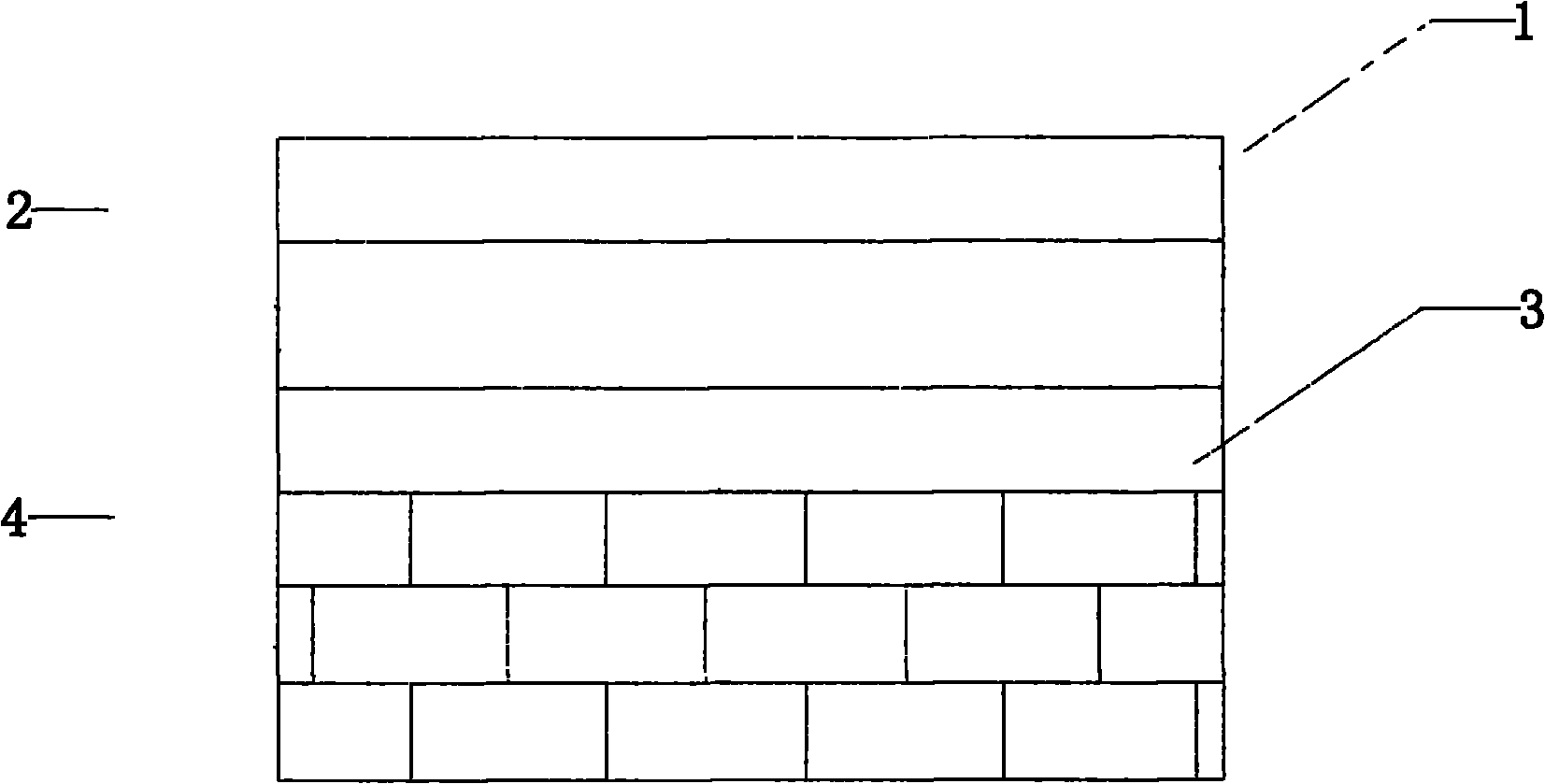

[0011] Such as figure 1 As shown, the cement fly ash foamed composite thermal insulation material of the present invention comprises a cement fly ash foamed thermal insulation outer layer 1, a sandwich composite layer 2, a cement fly ash foamed thermal insulation inner layer 3, and the sandwich The composite layer 2 is located between the cement fly ash foam insulation outer layer 1 and the cement fly ash foam insulation inner layer 3, the cement fly ash foam insulation inner layer 3 is connected with the building concrete body 4, and the sandwich composite layer 2 It is made of polystyrene board (ERS board), extruded toluene board (XPS board), rigid polyurethane foam and polystyrene particle slurry, and the cement fly ash foam insulation outer layer 1 and cement fly ash hair The foam insulation inner layer 3 is made of cement, fly ash and foaming material.

[0012] The composite sandwich insulation material used in the sandwich composite layer 2 is a multi-purpose insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com