Method for determining full penetration laser welding process parameter of sheet

A technology with process parameters and full penetration, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of unstable welding seam formation, long cycle, high cost, and ensure welding seam quality, short working cycle, high cost, etc. The effect of low welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

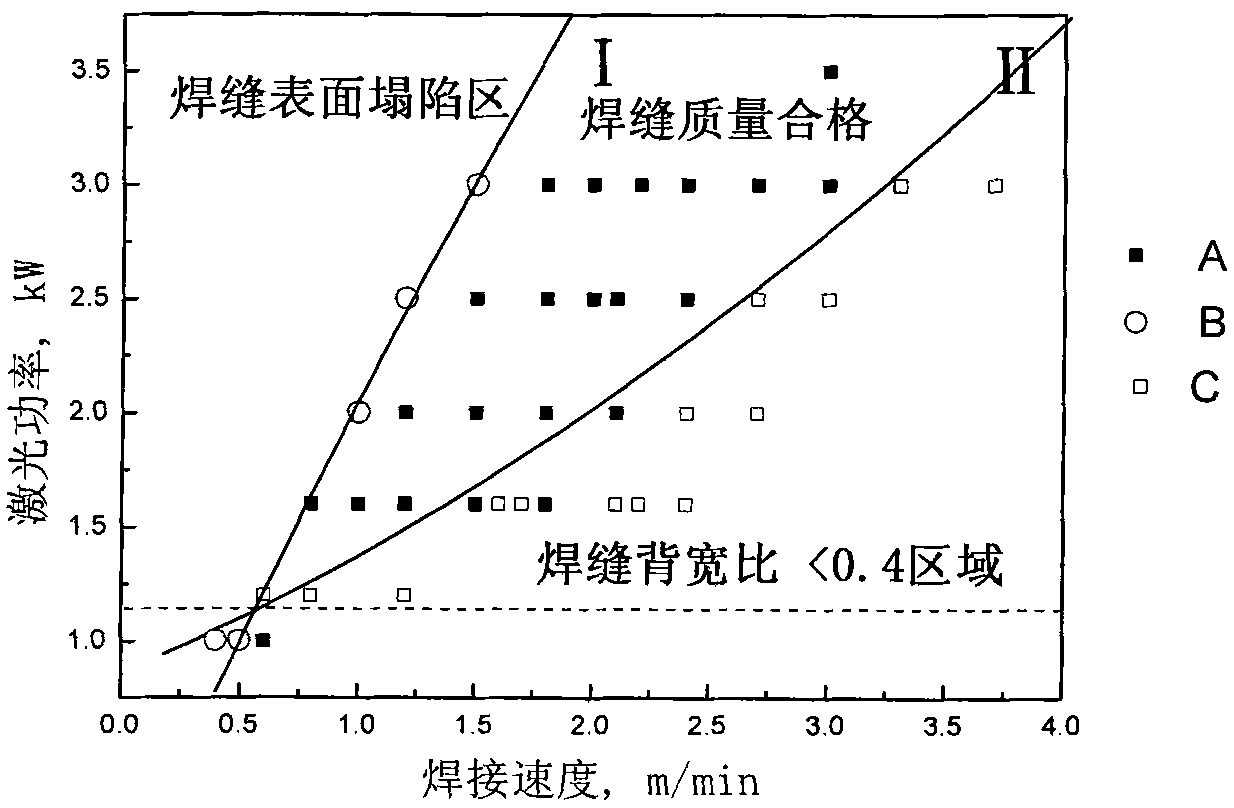

[0057] Example 1: Titanium Alloy Sheet CO 2 Laser welding

[0058] 1. Conditions of the embodiment: a thin titanium alloy plate with a plate thickness of 2.5 mm;

[0059] 2. The establishment of a process parameter window for full penetration laser welding of thin plates;

[0060] 2.1. Establish a coordinate system of laser welding process parameters; the ordinate is the laser power, and the abscissa is the welding speed;

[0061] 2.2. Conduct laser welding process test;

[0062] Using high power CO 2 Laser welding machine for laser full penetration welding;

[0063] 2.2.1. Determine the laser defocus amount; the laser defocus amount is in the range of -1mm to 1mm. When the focus of the laser beam is located on the front of the metal plate to be welded, the defocus amount is 0. When the focus of the laser beam is located below the front of the metal plate to be welded The amount of defocus is negative, otherwise it is positive;

[0064] 2.2.2. Determine the laser power p...

Embodiment 2

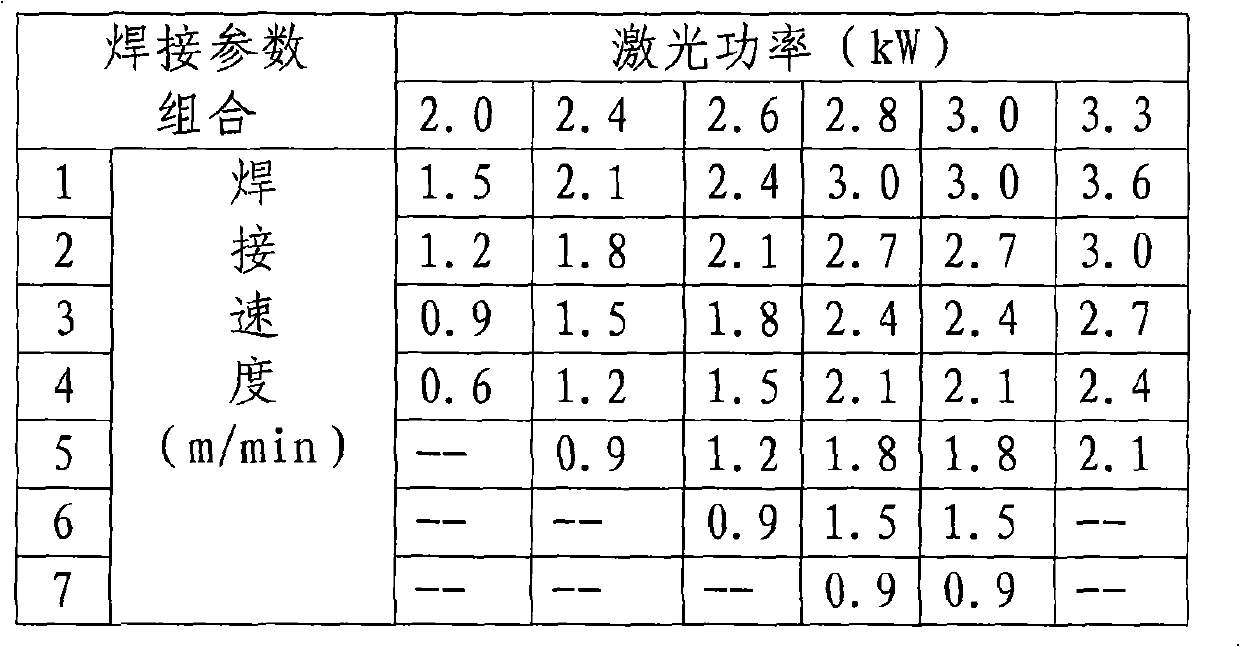

[0082] Embodiment 2: YAG laser welding of titanium alloy sheet

[0083] 1. Conditions of the embodiment: a thin titanium alloy plate with a plate thickness of 2.5 mm;

[0084] 2. The establishment of a process parameter window for full penetration laser welding of thin plates;

[0085] 2.1. Establish a coordinate system of laser welding process parameters; the ordinate is the laser power, and the abscissa is the welding speed;

[0086] 2.2. Conduct laser welding process test;

[0087] High-power YAG laser welding machine is used for laser full penetration welding;

[0088] 2.2.1. Determine the laser defocus amount; the laser defocus amount is in the range of -1mm to 1mm. When the focus of the laser beam is located on the front of the metal plate to be welded, the defocus amount is 0. When the focus of the laser beam is located below the front of the metal plate to be welded The amount of defocus is negative, otherwise it is positive;

[0089] 2.2.2. Determine the laser pow...

Embodiment 3

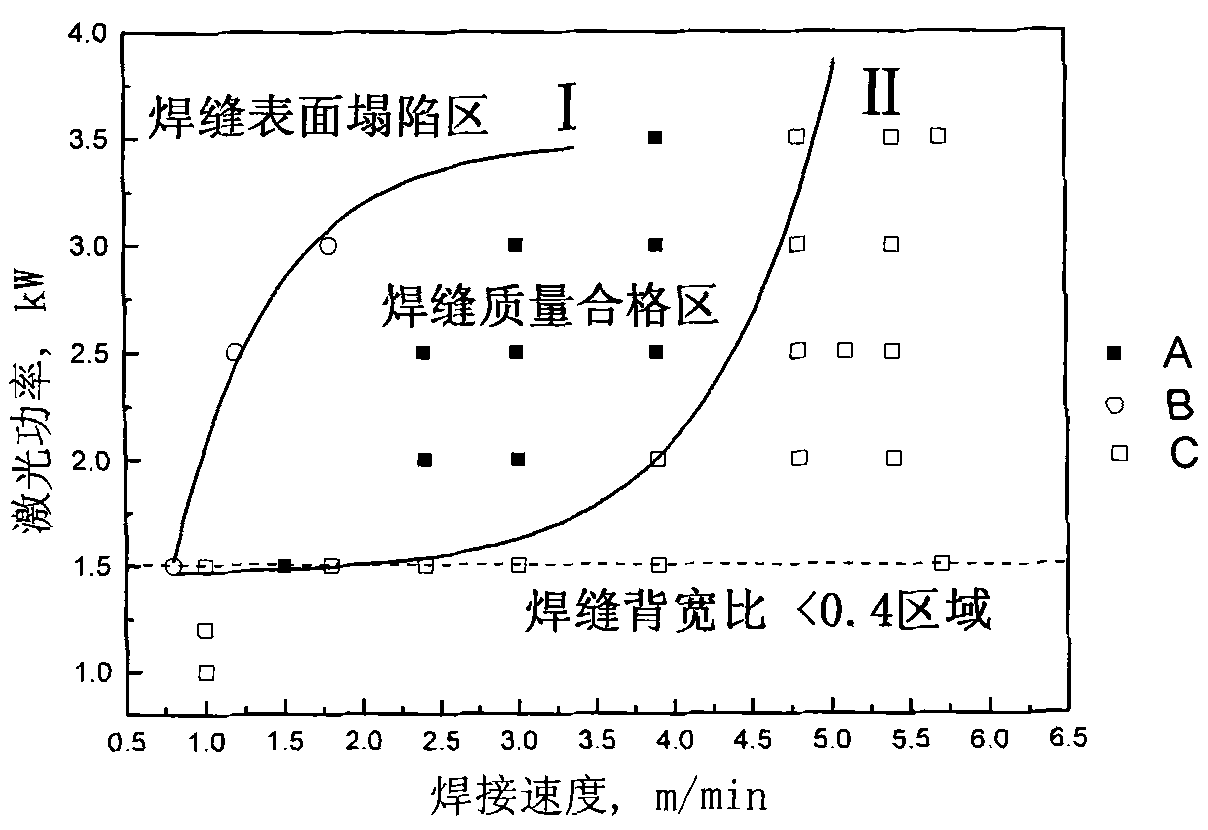

[0107] Embodiment 3: YAG laser welding of aluminum-lithium alloy sheet

[0108] 1. Conditions of the embodiment: an aluminum-lithium alloy thin plate with a plate thickness of 3 mm;

[0109] 2. The establishment of a process parameter window for full penetration laser welding of thin plates;

[0110] 2.1. Establish a coordinate system of laser welding process parameters; the ordinate is the laser power, and the abscissa is the welding speed;

[0111] 2.2. Conduct laser welding process test;

[0112] High-power YAG laser welding machine is used for laser full penetration welding;

[0113] 2.2.1. Determine the laser defocus amount; the laser defocus amount is in the range of -1mm to 1mm. When the focus of the laser beam is located on the front of the metal plate to be welded, the defocus amount is 0. When the focus of the laser beam is located below the front of the metal plate to be welded The amount of defocus is negative, otherwise it is positive;

[0114] 2.2.2. Determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com