Welding process of high-strength steel structure

A welding process and steel structure technology, applied in welding equipment, welding medium, welding equipment, etc., can solve problems such as construction difficulties and inability to meet, achieve good welding effect, avoid weld cracks, and improve conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

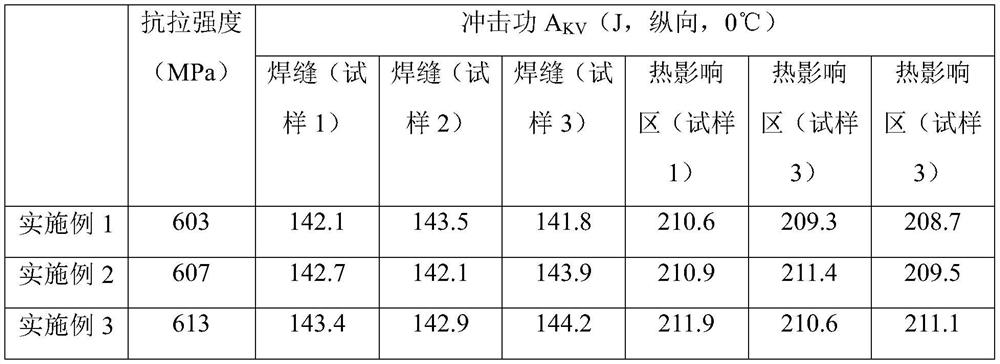

Embodiment 1

[0029] A welding process for a high-strength steel structure, the specific steps are as follows:

[0030] (1) First process the "V"-shaped groove on the steel structure to be welded. The groove angle is 60°, and the gap at the widest part of the groove is 1mm. Preheat to 110°C;

[0031] (2) Then use the H03Cr22Ni8Mo3N duplex stainless steel welding wire to carry out argon arc welding for backing. The specific process conditions are: current 70A, voltage 10V, welding speed 8mm / min; the protective gas used is argon, and the flow rate of argon is 8L / min ;

[0032] (3) Use welding rods to carry out electric welding construction of the filling layer and the cover surface. The process conditions of the electric welding construction of the filling layer are: welding current 140A, voltage 20V, and welding speed 18cm / min; the process conditions of the cover surface electric welding construction are: welding current 100A, Voltage 30V, welding speed 25cm / min;

[0033] (4) Immediately ...

Embodiment 2

[0042] A welding process for a high-strength steel structure, the specific steps are as follows:

[0043] (1) First process the "V"-shaped groove on the steel structure to be welded. The groove angle is 60°, and the gap at the widest part of the groove is 1mm. Preheat to 120°C;

[0044] (2) Then use the H03Cr22Ni8Mo3N duplex stainless steel welding wire to carry out argon arc welding for backing. The specific process conditions are: current 60A, voltage 12V, welding speed 6mm / min; the protective gas used is argon, and the flow rate of argon is 10L / min ;

[0045] (3) Use welding rods to carry out electric welding construction of the filling layer and the cover surface. The process conditions of the electric welding construction of the filling layer are: welding current 130A, voltage 30V, and welding speed 15cm / min; the process conditions of the cover surface electric welding construction are: welding current 110A, Voltage 20V, welding speed 30cm / min;

[0046] (4) After weldi...

Embodiment 3

[0055] A welding process for a high-strength steel structure, the specific steps are as follows:

[0056] (1) First process the "V"-shaped groove on the steel structure to be welded. The groove angle is 60°, and the gap at the widest part of the groove is 1mm. Preheat to 115°C;

[0057] (2) Then use the H03Cr22Ni8Mo3N duplex stainless steel welding wire for argon arc welding as the base, the specific process conditions are: current 65A, voltage 11V, welding speed 7mm / min; the protective gas used is argon, and the flow rate of argon is 9L / min ;

[0058] (3) Reuse the welding rod to carry out the electric welding construction of the filling layer and the cover surface. The process conditions of the electric welding construction of the filling layer are: welding current 135A, voltage 25V, and welding speed 16cm / min; the process conditions of the cover surface electric welding construction are: welding current 105A, Voltage 25V, welding speed 28cm / min;

[0059] (4) After weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com