Method for manufacturing novel lithium iron battery

A technology for iron-lithium batteries and lithium-ion batteries, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as unfavorable reversible reactions, sharp drop in cycle performance, and defects in crystal lattices, and improve high-current discharge performance and safety performance, high-current discharge performance enhancement, and the effect of increasing the design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

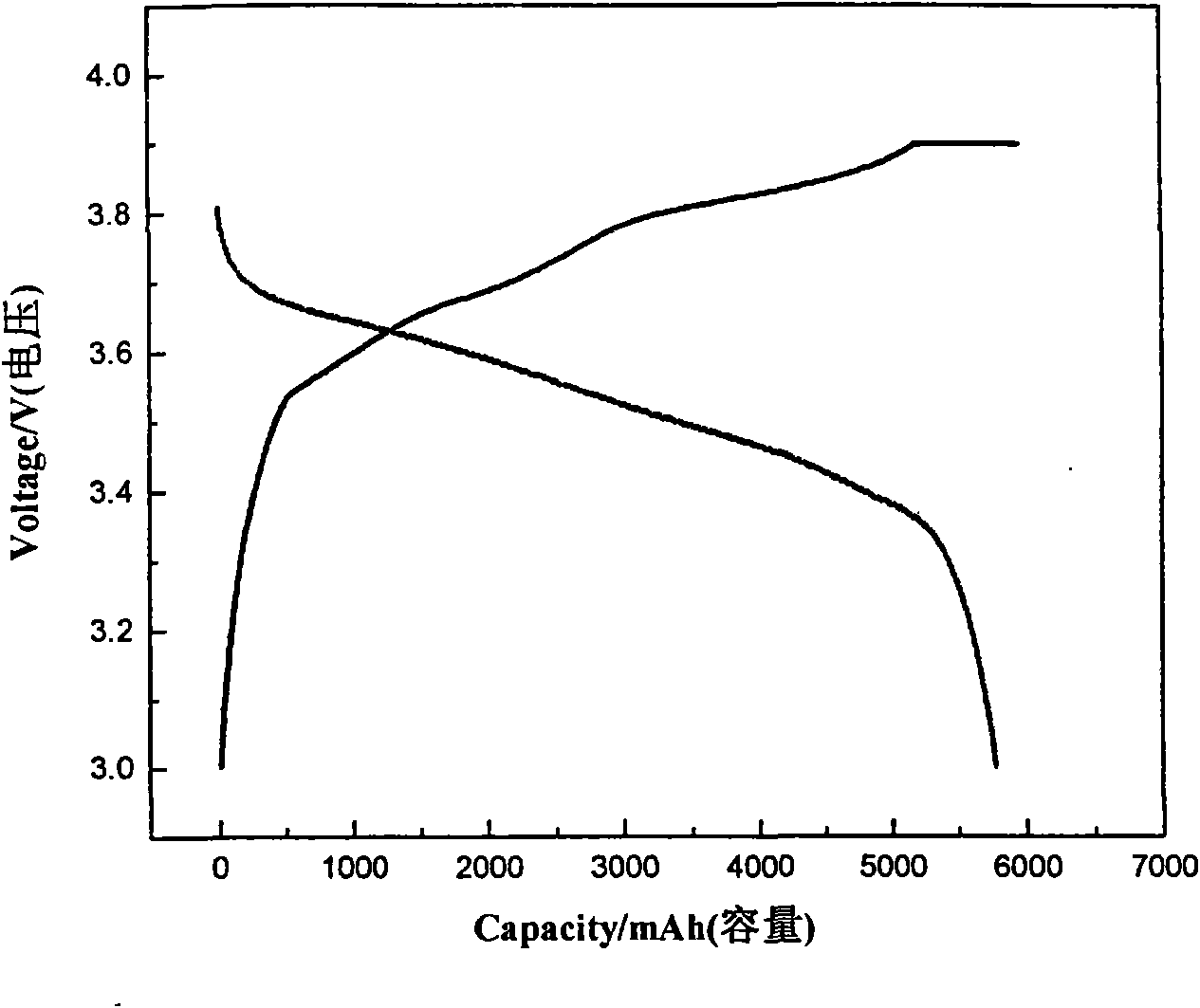

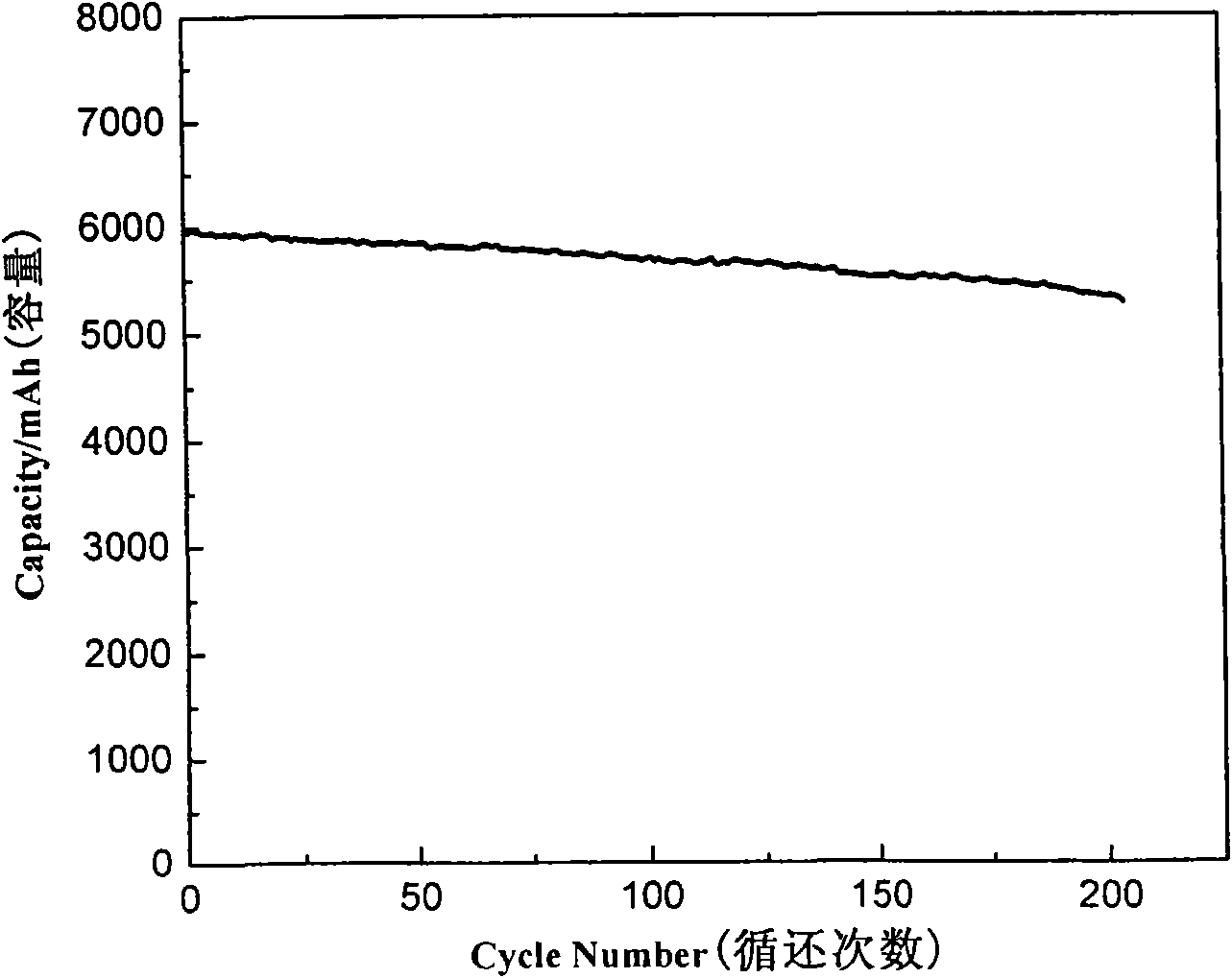

[0031] Example 1: The positive active material contains 5% LiMn by mass 2 O 4 And 95% FeF 3 / V 2 O 5 Composite material (FeF 3 With V 2 O 5 According to the mass ratio of 99%:1%, high-energy ball milling for 1 hour, and then annealing at 600°C for 12 hours), the core adopts a new type of rewind design of lithium iron battery.

[0032] The preparation method of the positive active material according to the present invention is as follows: using FeF 3 / V 2 O 5 Composite materials and LiMn 2 O 4 The combination is used as a positive electrode active material and combined with a carbon negative electrode to form a new type of iron-lithium lithium ion battery. The positive electrode active material consists of 5%-85% LiMn 2 O 4 And 95%-15% FeF 3 / V 2 O 5 Composite material composition. Before preparing the positive active material, prepare FeF 3 / V 2 O 5 Composite materials. The composite material will account for 1%-50% of the total mass of the composite material. 2 O 5 With FeF acco...

Embodiment 2

[0034] Example 2: The positive active material contains 5% LiMn by mass 2 O 4 And 95% FeF 3 / V 2 O 5 Composite material (FeF 3 With V 2 O 5 According to the mass ratio of 99%:1%, high-energy ball milling for 1 hour, and then annealing at 600°C for 12 hours), the core does not use a new type of rewinding lithium iron battery.

[0035] The preparation method of the positive active material according to the present invention is as follows: using FeF 3 / V 2 O 5 Composite materials and LiMn 2 O 4 The combination is used as a positive electrode active material and combined with a carbon negative electrode to form a new type of iron-lithium lithium ion battery. The positive electrode active material consists of 5%-85% LiMn 2 O 4 And 95%-15% FeF 3 / V 2 O 5 Composite material composition. Before preparing the positive active material, prepare FeF 3 / V 2 O 5 Composite materials. The composite material will account for 1%-50% of the total mass of the composite material. 2 O 5 With FeF accou...

Embodiment 3

[0037] Example 3: The positive active material contains 85% LiMn by mass 2 O 4 And 15% FeF 3 / V 2 O 5 Composite material (FeF 3 With V 2 O 5 According to the mass ratio of 50%:50% high-energy ball milling for 8 hours, and then annealing at 100°C for 1 hour), the core adopts a new type of rewind design of iron-lithium battery.

[0038] The preparation method of the positive active material according to the present invention is as follows: using FeF 3 / V 2 O 5 Composite materials and LiMn 2 O 4 The combination is used as a positive electrode active material and combined with a carbon negative electrode to form a new type of iron-lithium lithium ion battery. The positive electrode active material consists of 5%-85% LiMn 2 O 4 And 95%-15% FeF 3 / V 2 O 5 Composite material composition. Before preparing the positive active material, prepare FeF 3 / V 2 O 5 Composite materials. The composite material will account for 1%-50% of the total mass of the composite material. 2 O 5 With FeF acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com