Electronically-controlled common rail heavy oil injector

A fuel injector and common rail technology, applied in the field of electronically controlled common rail fuel injectors, can solve the problems of large volume of the inner booster structure, interference, fluctuation of servo oil pressure, etc., to avoid corrosion and thermal damage, Improve work stability and save installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

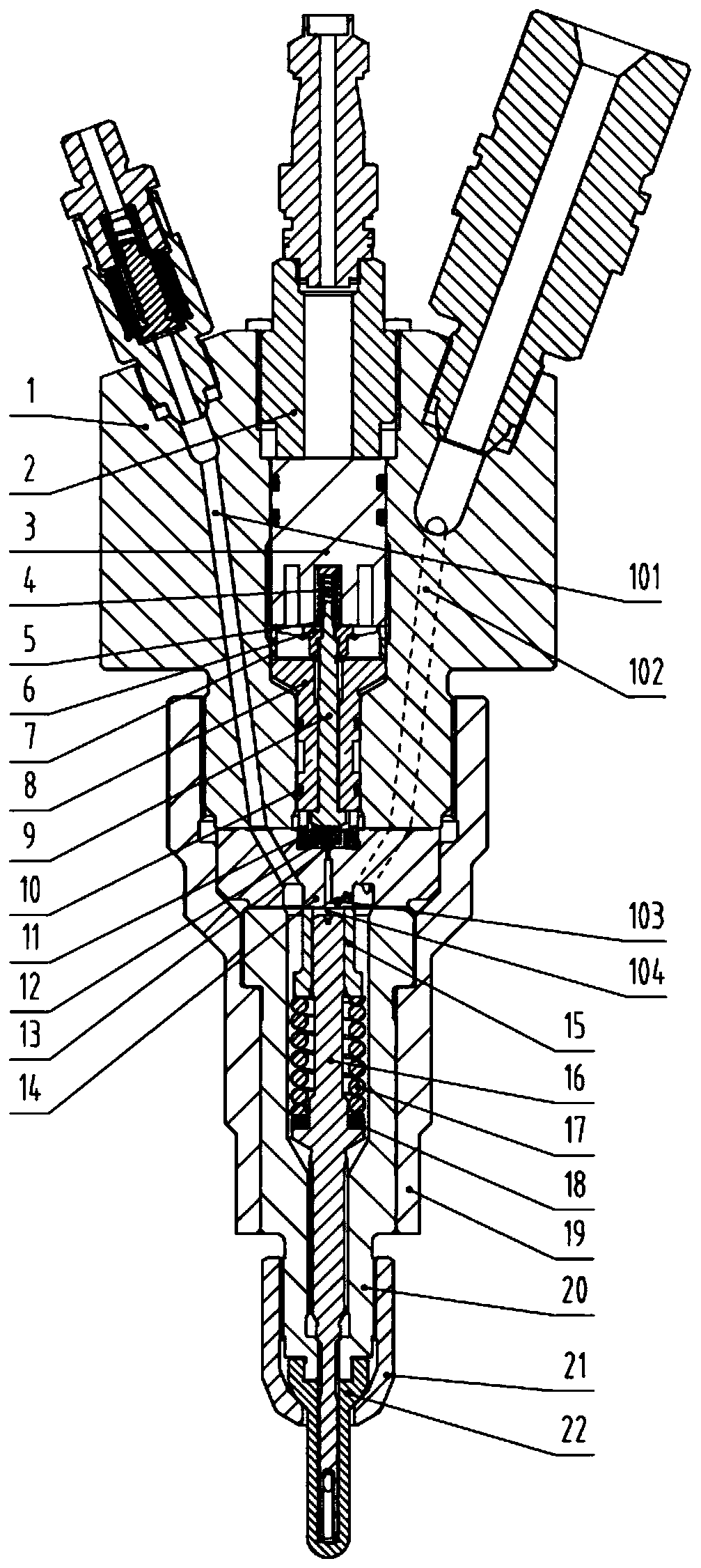

[0033] figure 1 Shown is an electronically controlled common rail heavy fuel injector with a specific structure, which includes three parts: the injector body, the electro-hydraulic control component, and the nozzle component.

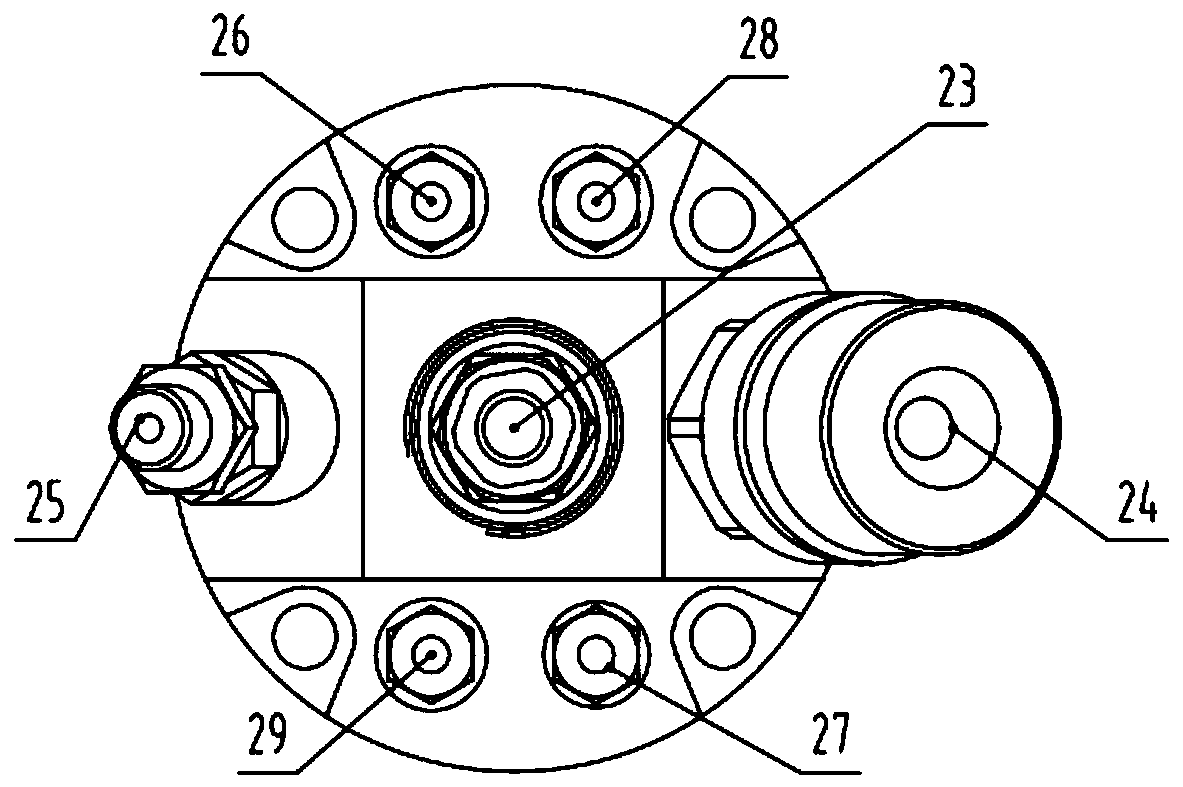

[0034] combinefigure 1 with figure 2 It can be seen that an electronic interface (23) is arranged in the middle of the top of the injector body (1) of the fuel injector, and an oil inlet interface (24), a circulating oil interface (25), and a cooling oil inlet interface ( 26), cooling oil outlet port (27), oil return port (28), mixed oil port (29), respectively connected with electromagnet (3) wire end, oil inlet oil passage (102), circulating oil oil passage (101) , cooling oil inlet passage (107), cooling oil return passage (108), fuel oil return passage (105), mixed oil discharge passage (106) are connected.

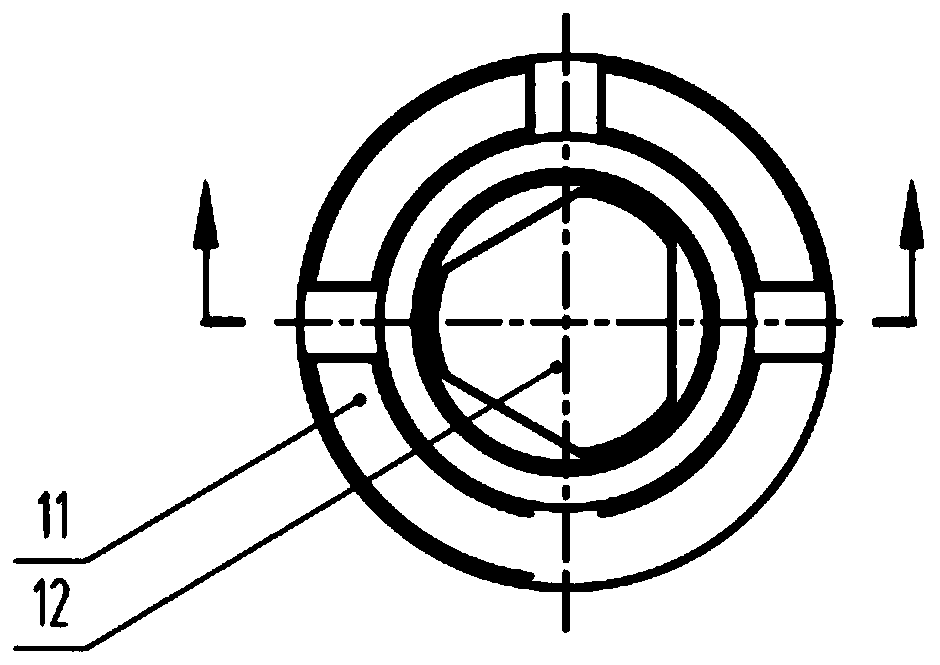

[0035] The structural com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com