Burn-up measurement system for spent fuel assembly

A measurement system and technology of spent fuel, applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of no automatic control mechanical parts, long measurement device length, unsuitable installation and measurement, etc. The effect of a compact measurement system and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions provided by the present invention will be further elaborated below in conjunction with the accompanying drawings.

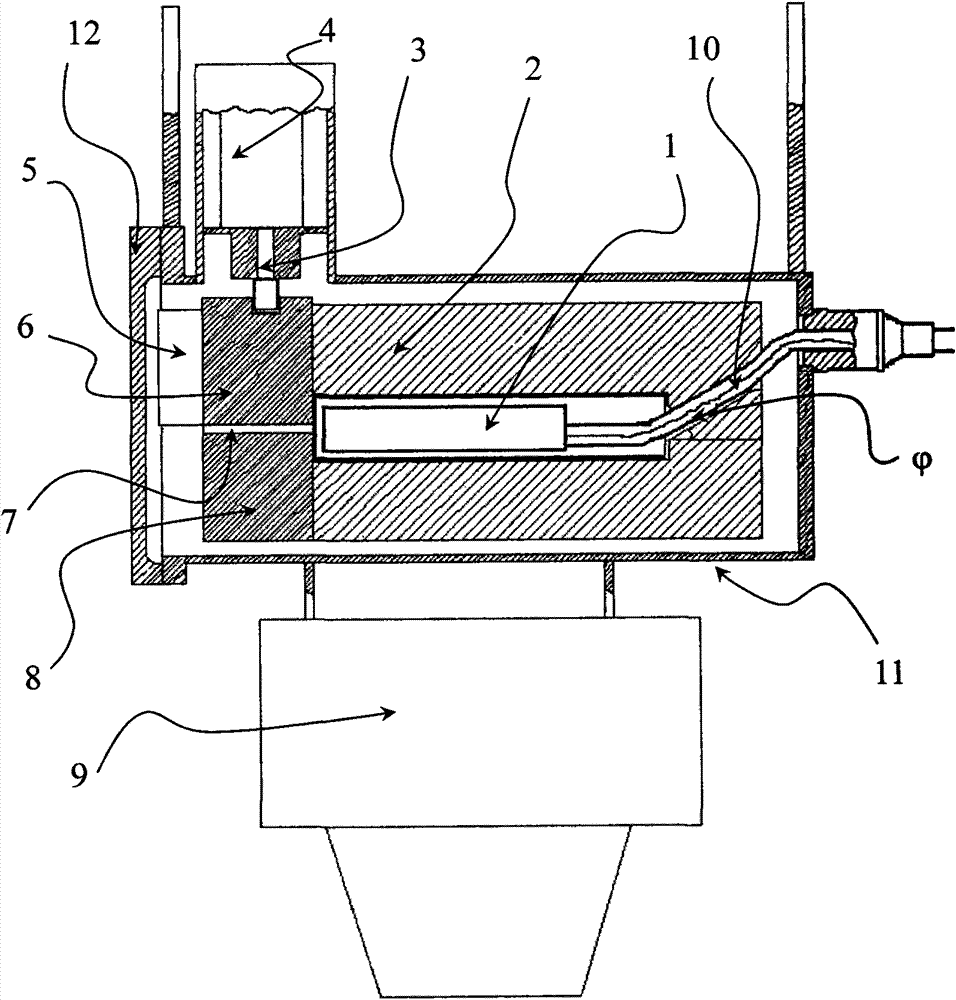

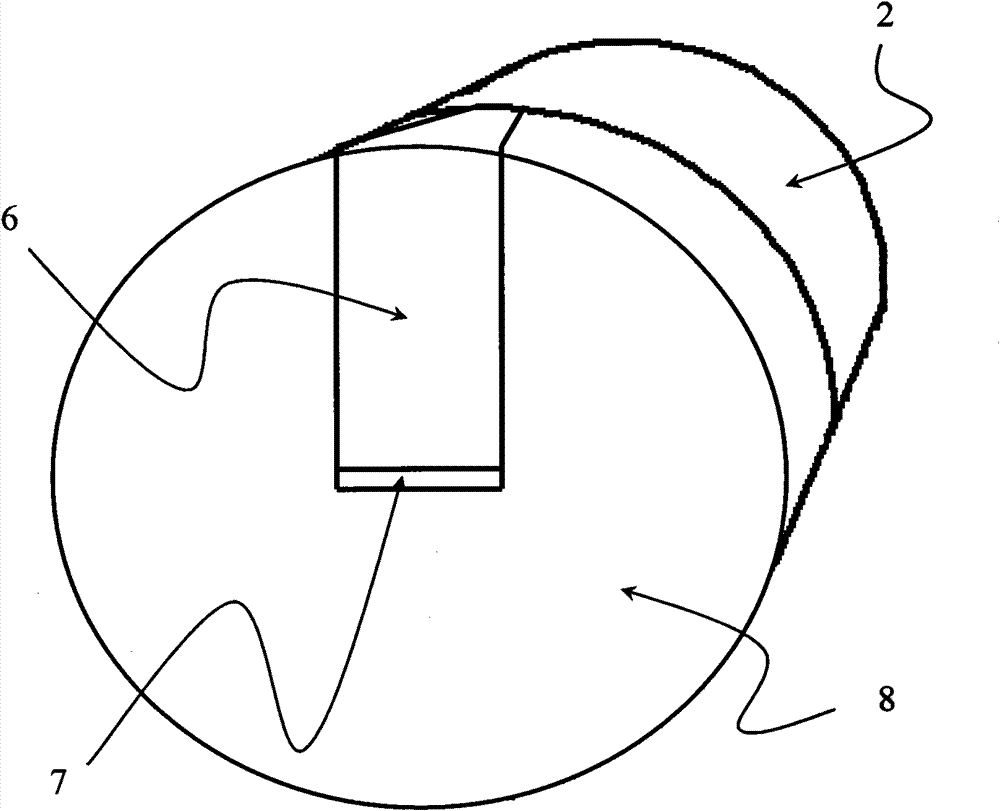

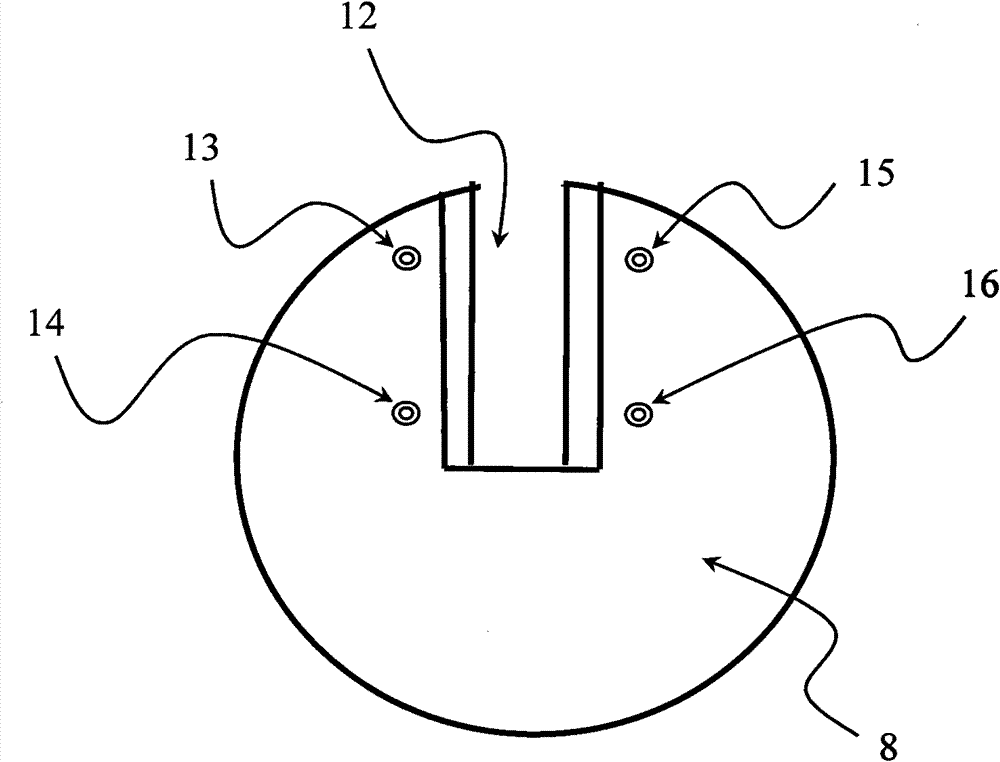

[0018] like figure 1 As shown, a spent fuel assembly gamma spectrum detection system is mainly composed of the following parts: CZT detector 1, digital multi-channel analyzer (including spectrum acquisition and analysis software), shielding body 2, shielding collimator 8, And a pressure-resistant sealed container 11.

[0019] This embodiment adopts the CPG type CZT detector 1 (crystal size is 15×15×7.5mm) of American EV Product Company 3 ), the energy range is 30keV~10MeV, the detector shell is cylindrical (Φ38.1mm×159.5mm), for 137 The 662keV energy resolution of the Cs point source is better than 2%.

[0020] The digital multi-channel analyzer is the Inspec2000 multi-channel analyzer of CANBERRA Company in the United States, and the spectrum acquisition and analysis software is the commercial software Genie2000 of the company. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com