Ash-slag cooling and sorting device and circulating fluidized bed boiler using same

A circulating fluidized bed, ash and slag cooling technology, applied in fluidized bed combustion equipment, solid separation, chemical instruments and methods, etc., can solve problems such as water leakage, slag leakage, etc. Good performance, the effect of restricting dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Only fluidized bed slag cooler is used.

[0049] When there are few large particles in the furnace fuel (the mass percentage of particles above 10mm does not exceed 5% of the total ash), only the fluidized bed slag cooler is used. At this time, the same as the circulating fluidized bed boiler using the fluidized bed slag cooler, there is no change in the slag cooler and its connection with the boiler and the layout of the boiler island. channel.

Embodiment 2

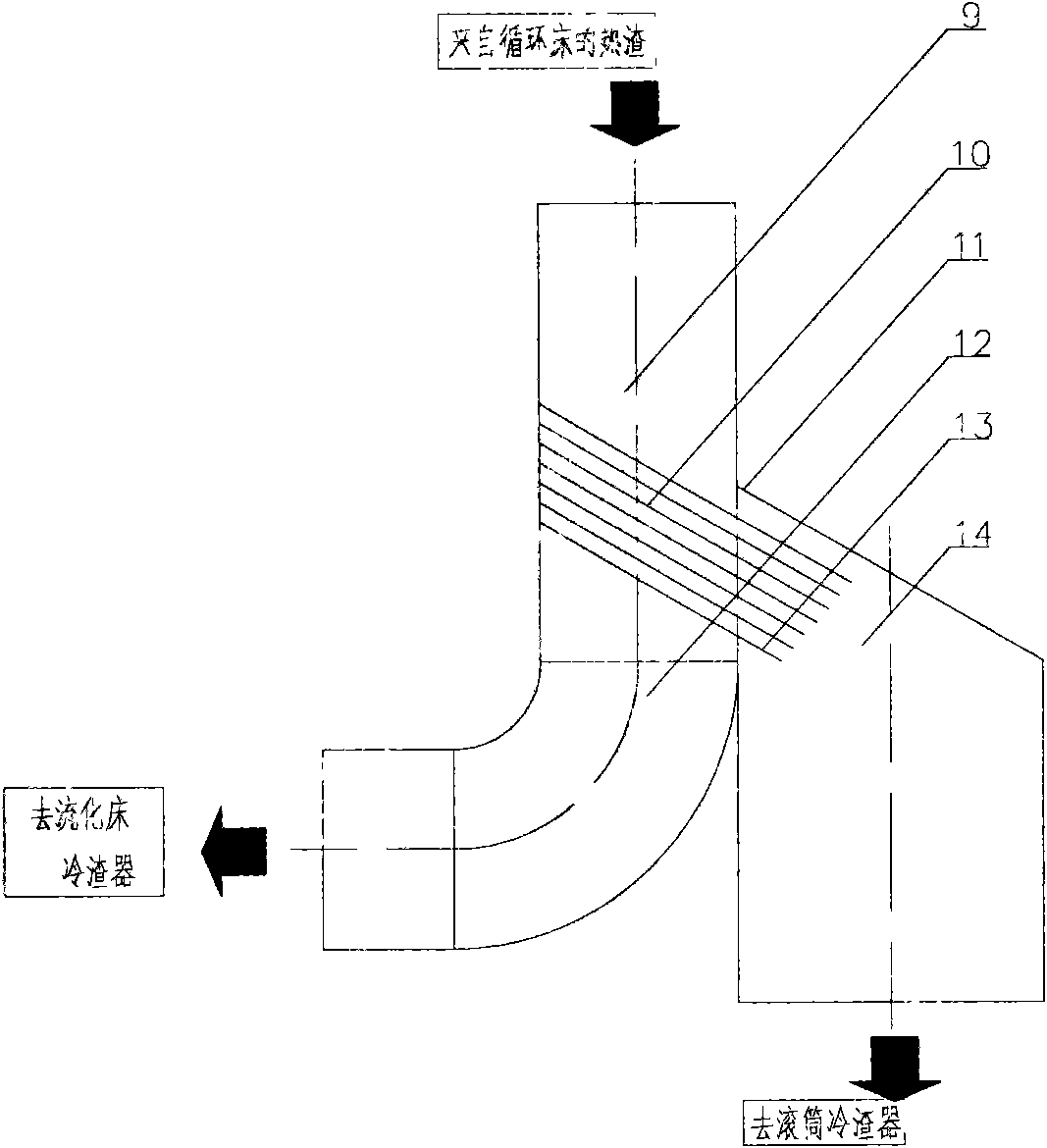

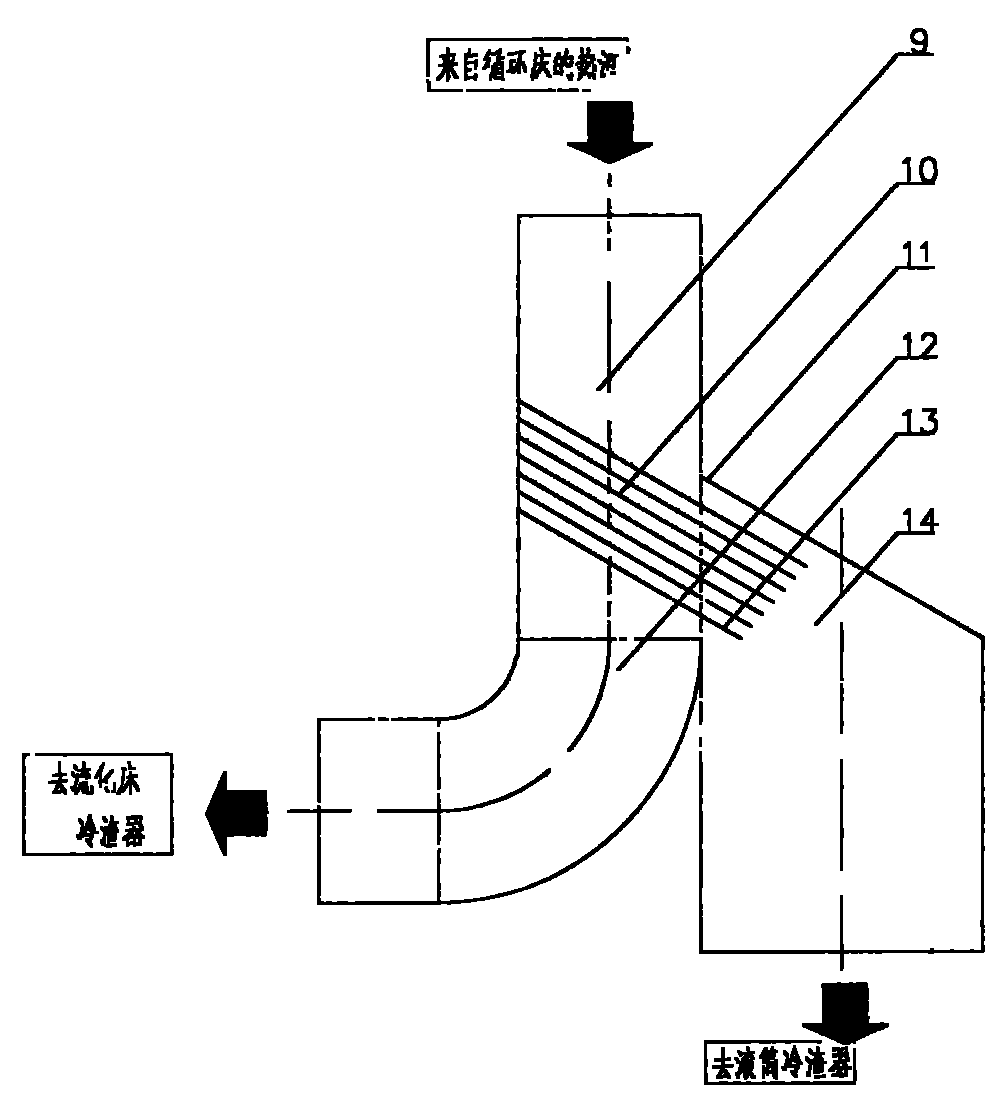

[0051] The cold slag discharge of a circulating fluidized bed boiler is 100t / h, and the particles exceeding 10mm in the furnace fuel account for 23% of the total particle mass. Taking 8mm as the cut-off point of ash size, large particles account for about 30% of the total mass at this time.

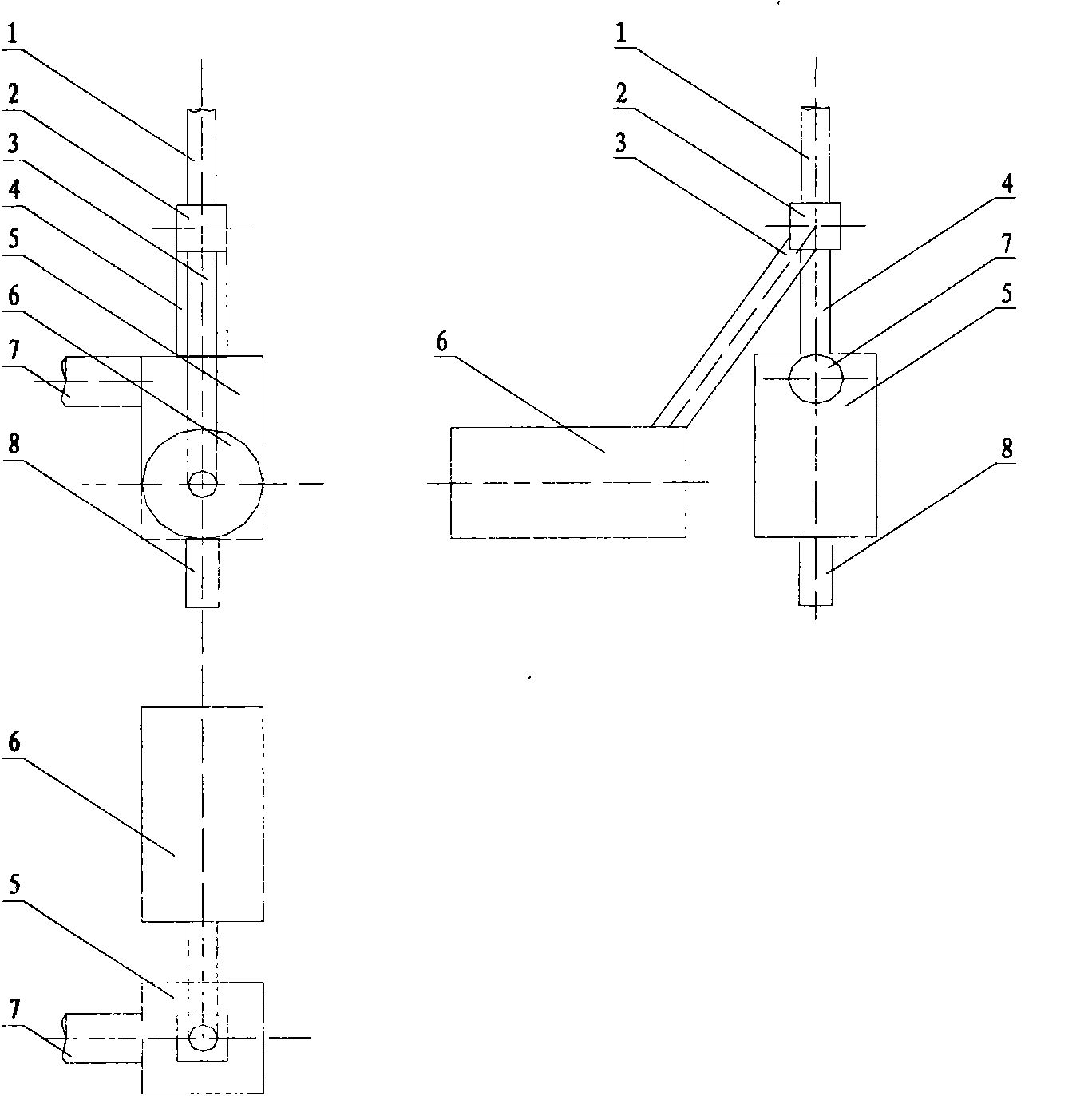

[0052] The hot ash sorting mechanism adopts high-temperature and wear-resistant metal strips with a diameter of 15mm, which are arranged in 3 layers at an angle of 50 degrees to the horizontal. The pitch of the first layer is 35mm, sorting out the particles larger than 20mm; the pitch of the second layer is 27mm, sorting out the particles larger than 12mm; the pitch of the third layer is 23mm, sorting out the particles larger than 8mm.

[0053] Equipped with a 4-chamber water-cooled drum slag cooler with a slag import and export center distance of 4m and a diameter of 1.4m, it can cool 25,000kg / h ash from 850°C to 160°C at a speed of 9rpm.

[0054] The fluidized bed slag cooler is design...

Embodiment 3

[0056] The cold slag discharge of a circulating fluidized bed boiler is 200t / h, and the particles exceeding 10mm in the furnace fuel account for 23% of the total particle mass. Taking 4mm as the cut-off point of ash size, large particles account for about 50% of the total mass at this time.

[0057] The hot ash sorting mechanism adopts high temperature and wear-resistant metal strips with a diameter of 15mm, and is arranged in 5 layers at an angle of 50 degrees with the horizontal. The pitch of the first layer is 35mm, sorting out the particles larger than 20mm; the pitch of the second layer is 27mm, sorting out the particles larger than 12mm; the pitch of the third layer is 23mm, sorting out the particles larger than 8mm; the fourth layer of pitch The pitch of the fifth layer is 19mm, and the particles larger than 4mm are sorted out.

[0058] Equipped with 4 water-cooled drum slag coolers with 4 chambers and a diameter of 1.4m, the center distance between the import and expo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com