Alloy for fusible plug and fusible plug

A technology for fusible plugs and alloys, which is applied in the field of alloys for fusible plugs, and can solve problems such as the use of alloys that cannot be used for fusible plugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An alloy for a fusible plug and a fusible plug according to the present invention were produced, and their characteristics were compared.

[0030] The fusible alloys shown in Table 1 and Table 2 were prepared, and the heating curves from the differential thermal analysis of each alloy composition were measured, including the starting point of the endothermic peak, the lowest point of the endothermic peak, and the end point of the endothermic peak, and the solid Phase temperature, peak temperature, liquidus temperature. The melting temperature of each alloy is shown in Table 1 and Table 2.

[0031] In Table 1, Comparative Examples 4 and 5 are alloys for fusible plugs of Patent Documents 2 and 3.

[0032] The measurement conditions of the melting temperature are as follows.

[0033] 1. Determination of Differential Thermal Analysis

[0034] ·Differential thermal analysis measuring device SII differential scanning calorimeter

[0035] ·Heating rate: 5deg / min

[0036] ...

Embodiment 2

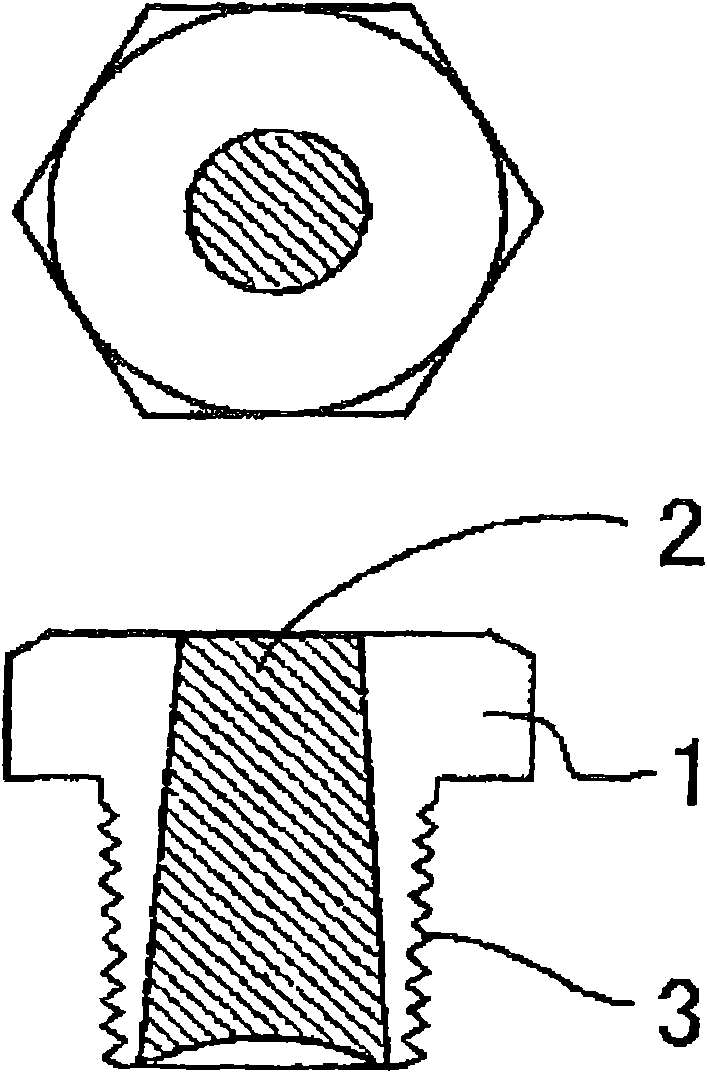

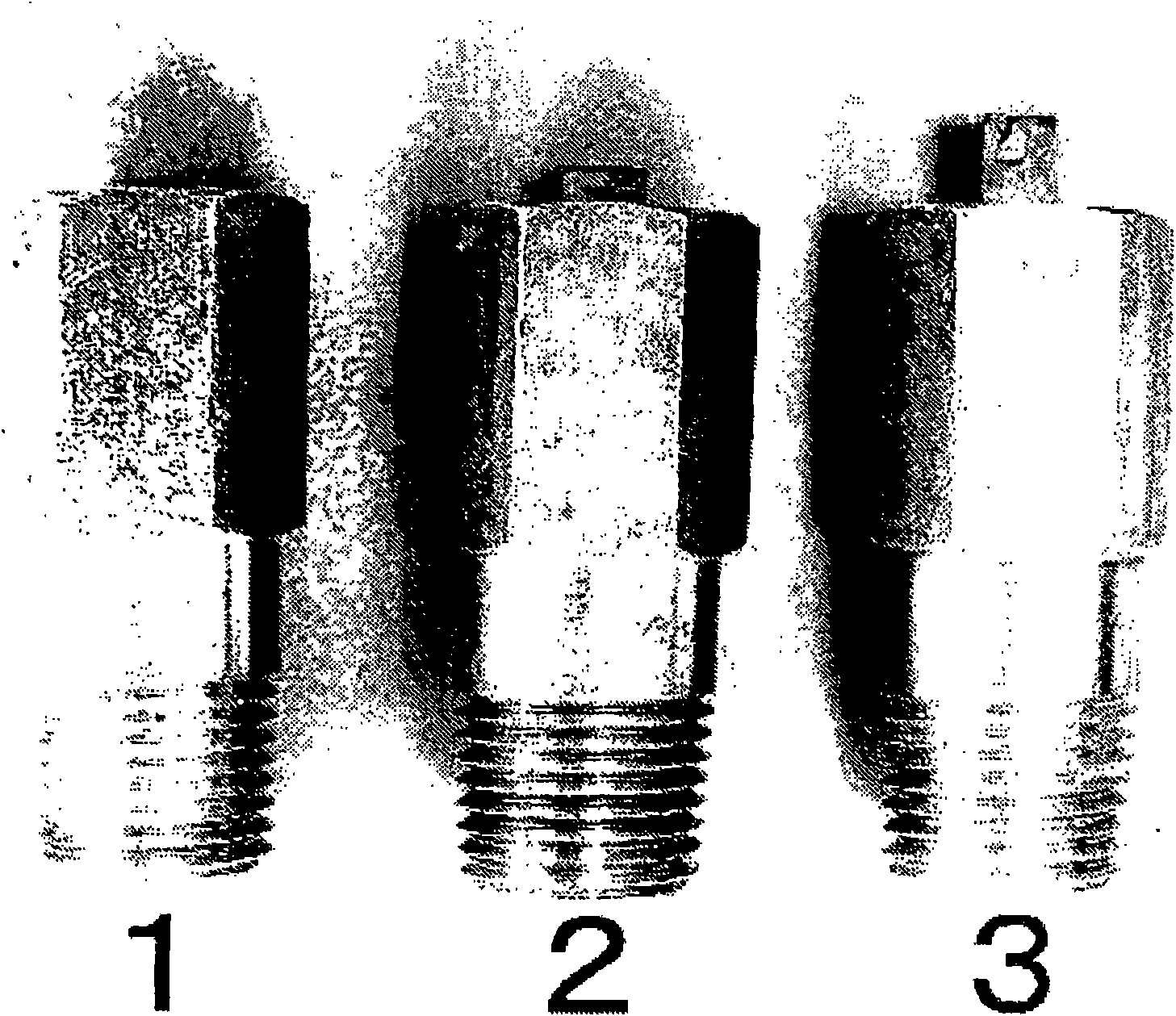

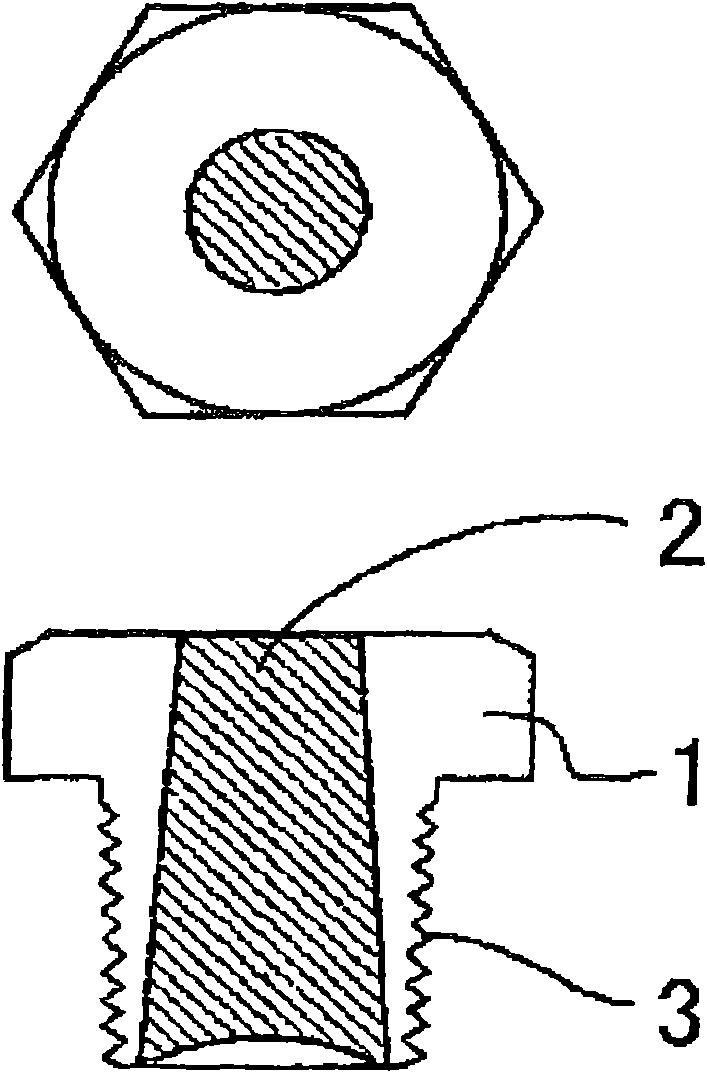

[0042] Secondly, in figure 1 The spacer 1 of the shown single-bolt type fusible plug is filled with the fusible plug alloys in Table 1 and Table 2 to make a fusible plug, and the creep characteristics of each alloy composition (called withstand voltage test) and the fusible plug are measured. plug operating temperature. A fusible plug with a total length of 28 mm and an inner diameter of a tip portion of 3 mm was used in the withstand voltage test and the operation test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com