Comber top comb spring pressure plate device

A technology of spring pressing plate and combing machine, which is applied in the direction of combing machine, textile and paper making, fiber processing, etc. It can solve the problems of rubber rod falling off, affecting work efficiency, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

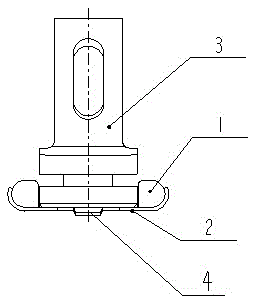

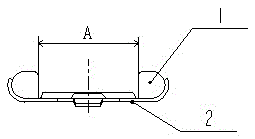

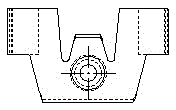

[0010] Such as figure 1 Described, a kind of combing machine top comb spring pressure plate device, comprises rubber rod 1, spring pressure plate 2, top comb support pin 3 and screw 4, the surface of described rubber rod 1 and spring pressure plate 2 needs roughening treatment and will The rubber rod 1 is glued to the semicircular edging at the two ends of the spring pressure plate 2, and the top comb support 3 is connected with the spring pressure plate 2 by a screw 4, and is connected with the top comb support 3. The contact surface of the contacting rubber rod 1 is a plane.

[0011] The present invention changes the contact surface between the rubber rod 1 and the top comb support 3 from the original circular surface to a plane, so that the distance A between the two rubber rods 1 increases, and is no longer squeezed by the top comb support 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com