Method for preparing high methane content gas from coal

A methane content and raw material technology, applied in the field of coal chemical industry, can solve the problems of low concentration of coal water slurry, unfavorable industrial production, increased energy consumption in the conversion process, etc., and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

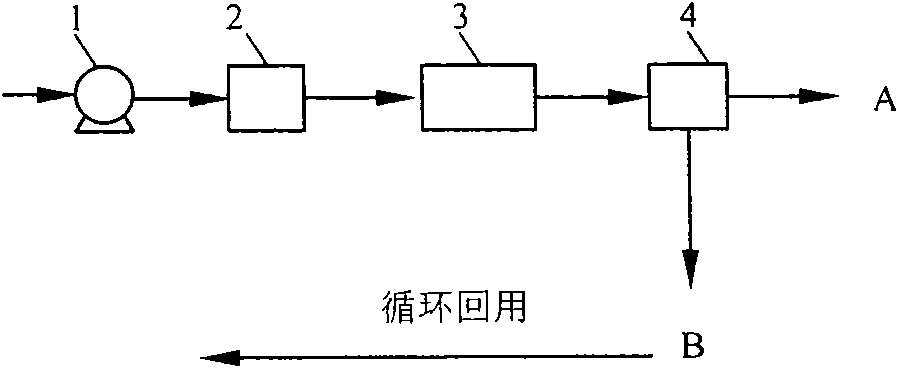

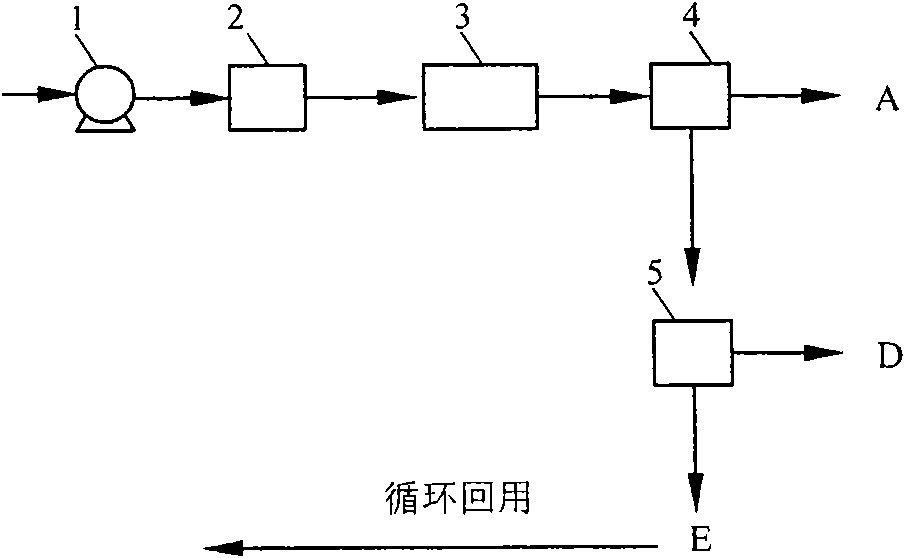

Method used

Image

Examples

Embodiment 1

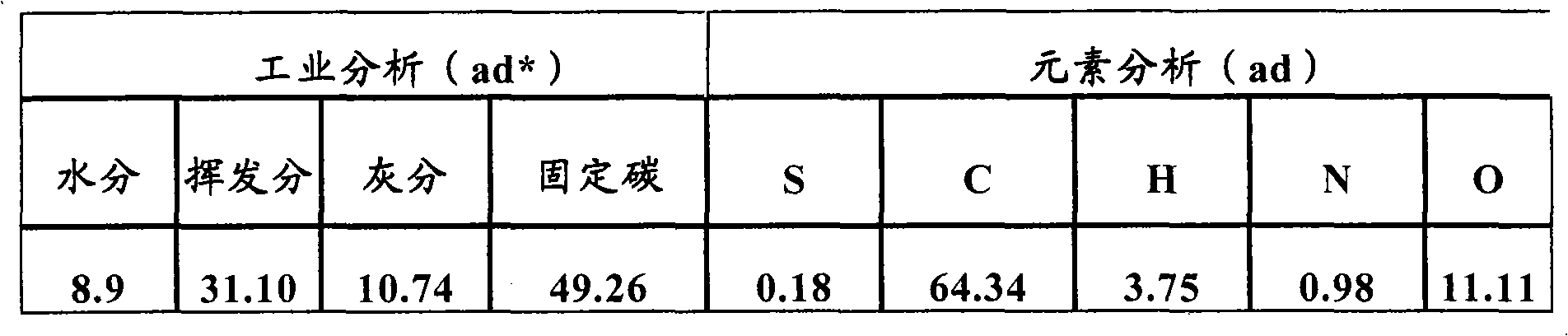

[0028] Weigh 12 g of 80-150 mesh coal powder (see Table 1 for coal quality analysis) and add it to the reactor, and add 1.2 g of potassium hydroxide to the coal powder. Utilize the high-pressure water pump to add in the reactor after the water is preheated by the preheater, and the addition amount is 60ml. Then, the reactor was heated so that the temperature reached 550° C. and the pressure reached 24 MPa, and samples were taken after reacting for 5 minutes, and gas-liquid separation was performed on the gas-liquid mixture obtained by the reaction. The data obtained by analyzing the gas products after catalytic pyrolysis are shown in Table 2.

[0029] Add 0.12g Ni / Al to the reaction residue 2 o 3 60 ml of water was added to the reactor through the preheater. Then, the reactor was heated so that the temperature reached 650° C. and the pressure reached 27 MPa. After reacting for 5 minutes, samples were taken, and the gas-liquid mixture obtained by the reaction was separated i...

Embodiment 2

[0036] Weigh 12g of 80-150 mesh coal powder and add it to the reactor, add 1.2g of potassium carbonate to the coal powder, and then add 60ml of water to the reactor. Then, the reactor was heated so that the temperature reached 550° C. and the pressure reached 24 MPa, and samples were taken after reacting for 5 minutes, and gas-liquid separation was performed on the gas-liquid mixture obtained by the reaction. The data obtained by analyzing the gas products after catalytic pyrolysis are shown in Table 3.

[0037] Add 0.12g Ni / Al to the reaction residue 2 o 3 and 60ml of water. Then, the reactor was heated so that the temperature reached 650° C. and the pressure reached 27 MPa. After reacting for 5 minutes, samples were taken, and the gas-liquid mixture obtained by the reaction was separated into gas and liquid. The data obtained by analyzing the gas product after methanation are shown in Table 3.

Embodiment 3

[0038] Embodiment 3 (comparative example)

[0039] Weigh 12g of 80-150mesh coal powder and add it into the reactor, add 1.2g of potassium carbonate to the coal sample and then add 60ml of water into the reactor. Then, the reactor was heated so that the temperature reached 650° C. and the pressure reached 27 MPa. After reacting for 5 minutes, samples were taken, and the gas-liquid mixture obtained by the reaction was separated into gas and liquid. The data obtained by analyzing the gas after the one-step gasification are shown in the last row of Table 3.

[0040] Table 3 Gas Analysis

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com