Method for separating immune globulin IgY(delta Fc) from goose blood

An immunoglobulin and goose blood technology is applied in the field of separation and purification of biologically active substances, and achieves the effects of high separation efficiency, simplified separation steps and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

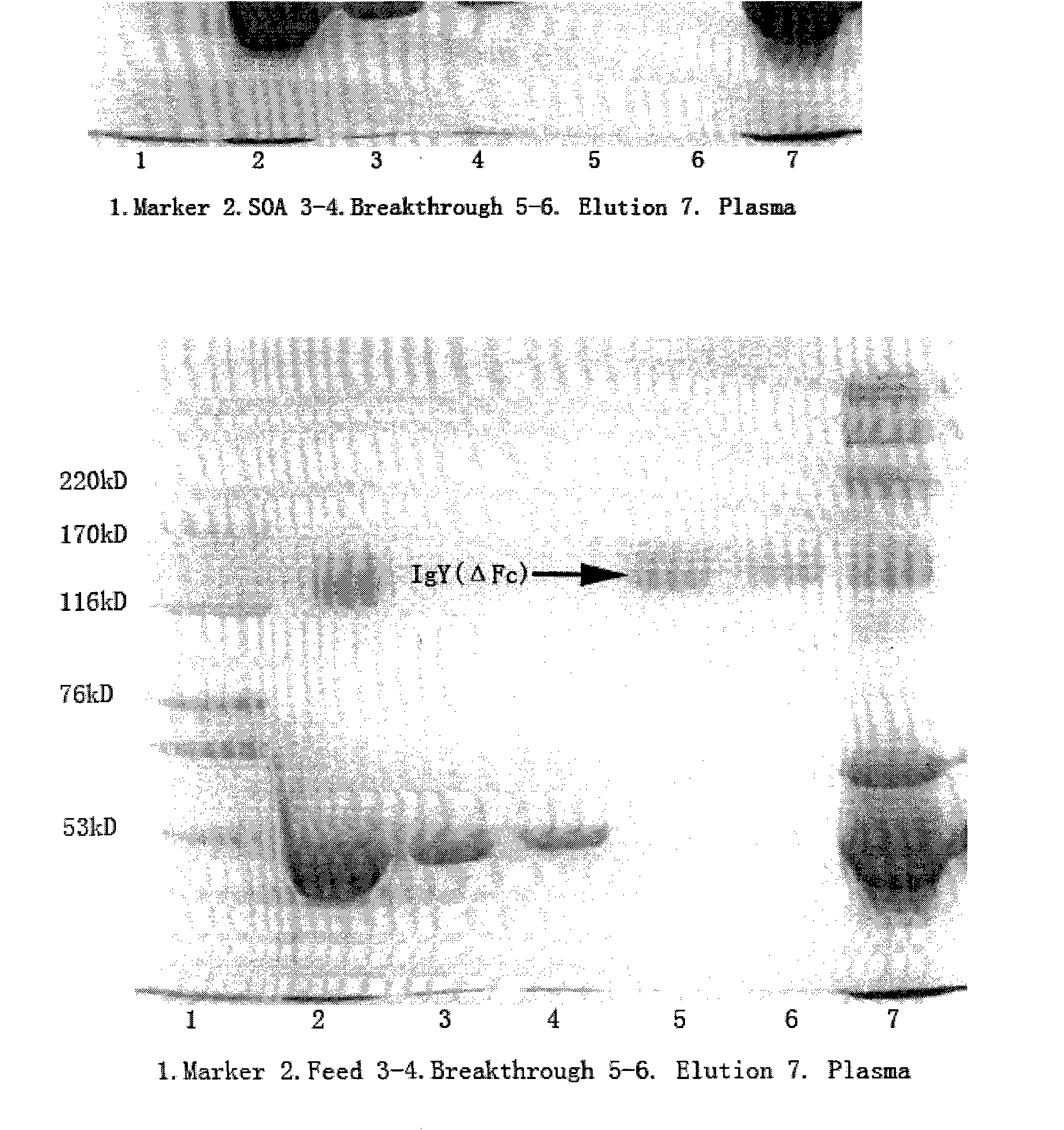

Image

Examples

Embodiment 1

[0022] Take fresh goose blood, add 0.1M sodium citrate solution according to the ratio of 9:1 (volume ratio) for anticoagulation, centrifuge at 2500rpm for 20 minutes in a centrifuge, remove red blood cells, and let stand at 4°C for 5 hours to remove the upper layer of fat. , and then added 300 mg of silica per milliliter of plasma, stirred at room temperature for 30 minutes, and filtered to obtain defatted plasma. Take 5ml of defatted plasma, add 5ml of 60mM acetic acid-sodium acetate buffer (pH4) and mix well to obtain 10ml of diluted plasma, add 600μl of caprylic acid, stir well, let stand at 4°C for 2 hours, and when the impurities are completely precipitated, centrifuge at 8000rpm for 30 minutes to obtain 9.5 ml of supernatant. The supernatant was filtered with a 0.45 μm filter, adjusted to pH 7.0, and 1 ml was taken as the injection sample. The column (inner diameter 1 cm) was filled with 5 ml of MEP Hypercel mixed mode medium, the equilibration buffer was 20 mM disodiu...

Embodiment 2

[0024] Take fresh goose blood, add 0.1M sodium citrate solution for anticoagulation according to the ratio of 9:1 (volume ratio), centrifuge at 3000rpm for 15 minutes in a centrifuge, remove red blood cells, and let stand at 8°C for 12 hours to remove the upper layer of fat. , and then added 1000 mg of silica per milliliter of plasma, stirred at room temperature for 60 minutes, and filtered to obtain defatted plasma. Take 5 ml of defatted plasma, add 15 ml of 60 mM acetic acid-sodium acetate buffer (pH 4.5) and mix well to obtain 20 ml of diluted plasma, add 600 μl of caprylic acid, stir well, stand at 4°C for 4 hours, and wait for the precipitation of impurity proteins to complete. Centrifuge at 10,000 rpm for 20 minutes to obtain 19.6 ml of supernatant. The supernatant was filtered with a 0.45 μm filter, adjusted to pH 5.0, and 2 ml was taken as the injection sample. The column (inner diameter 1cm) was filled with 5ml of MEP Hypercel mixed mode medium, the equilibration buf...

Embodiment 3

[0026]Take fresh goose blood, add 0.1M sodium citrate solution in a ratio of 9:1 (volume ratio) for anticoagulation, centrifuge at 3000rpm for 10 minutes in a centrifuge, remove red blood cells, and let stand at 4°C for 8 hours to remove the upper layer of fat. , and then added 300 mg of silica per milliliter of plasma, stirred at room temperature for 60 minutes, and filtered to obtain defatted plasma. Take 5ml of defatted plasma, add 20ml of 60mM acetic acid-sodium acetate buffer (pH 5.0) and mix well to obtain 25ml of diluted plasma, add 2500μl of caprylic acid, stir evenly, stand at 8°C for 4 hours, and when the impurity protein is completely precipitated, run at 10000rpm Centrifuge for 20 minutes to obtain 23.8 ml of supernatant. The supernatant was filtered with a 0.45 μm filter, adjusted to pH 6.0, and 1 ml was taken as the injection sample. The column (inner diameter 1cm) was filled with 5ml of MEP Hypercel mixed mode medium, the equilibration buffer was 20mM disodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com