Multi-stage drawing manufacturing method for superfine fluted tube

A manufacturing method and groove technology, applied in the field of heat pipe manufacturing, to achieve the effects of simple processing technology, easy operation, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The multi-drawing process of the present invention is used to manufacture micro-grooved tubes with an outer diameter of 3.0mm.

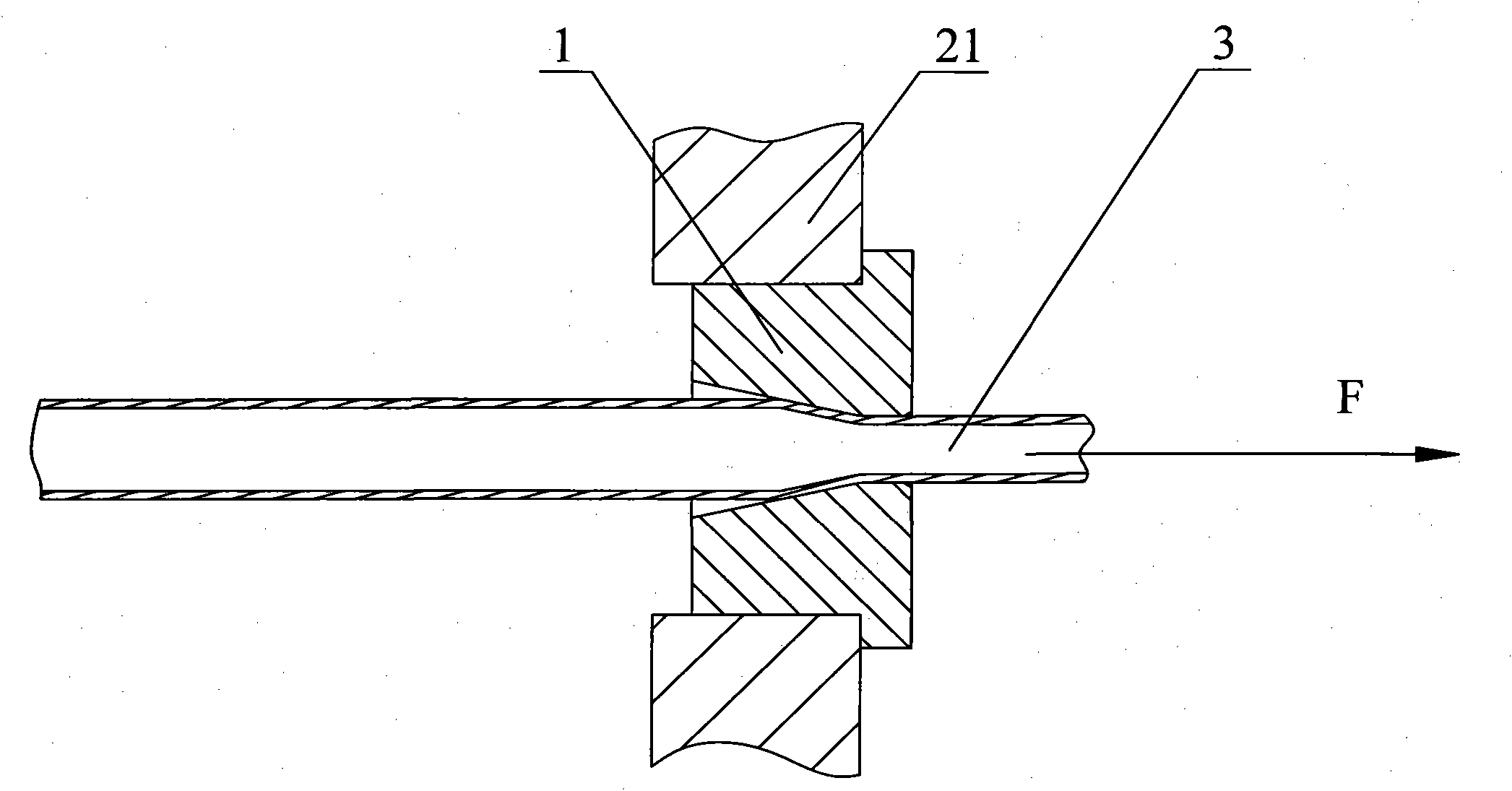

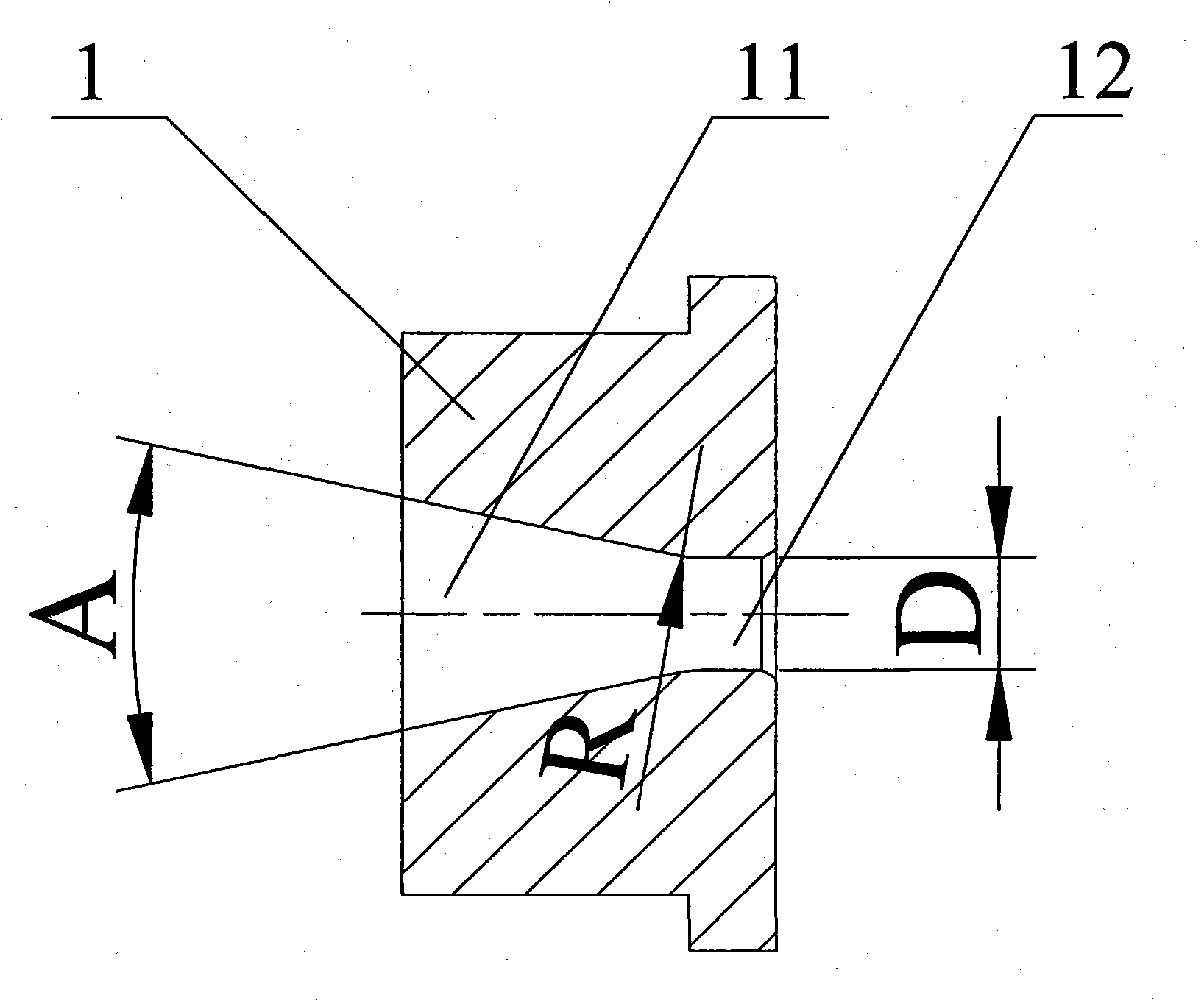

[0036] Such as figure 1 , 2 As shown, firstly a set of shrinking dies 1 needs to be designed and manufactured, including 4 shrinking dies, the diameter series are D1=5.5mm, D2=5.0mm, D3=4.0mm, D4=3.0mm. The shrink tube mold 1 is made of 45# steel, and the taper angle range of the lead-in section 11 is 30°. A circular arc R=0.5mm is used for a smooth transition between the introduction section 11 and the shaping section 12, the surface hardness is HRC40, and the surface roughness is Ra0.8.

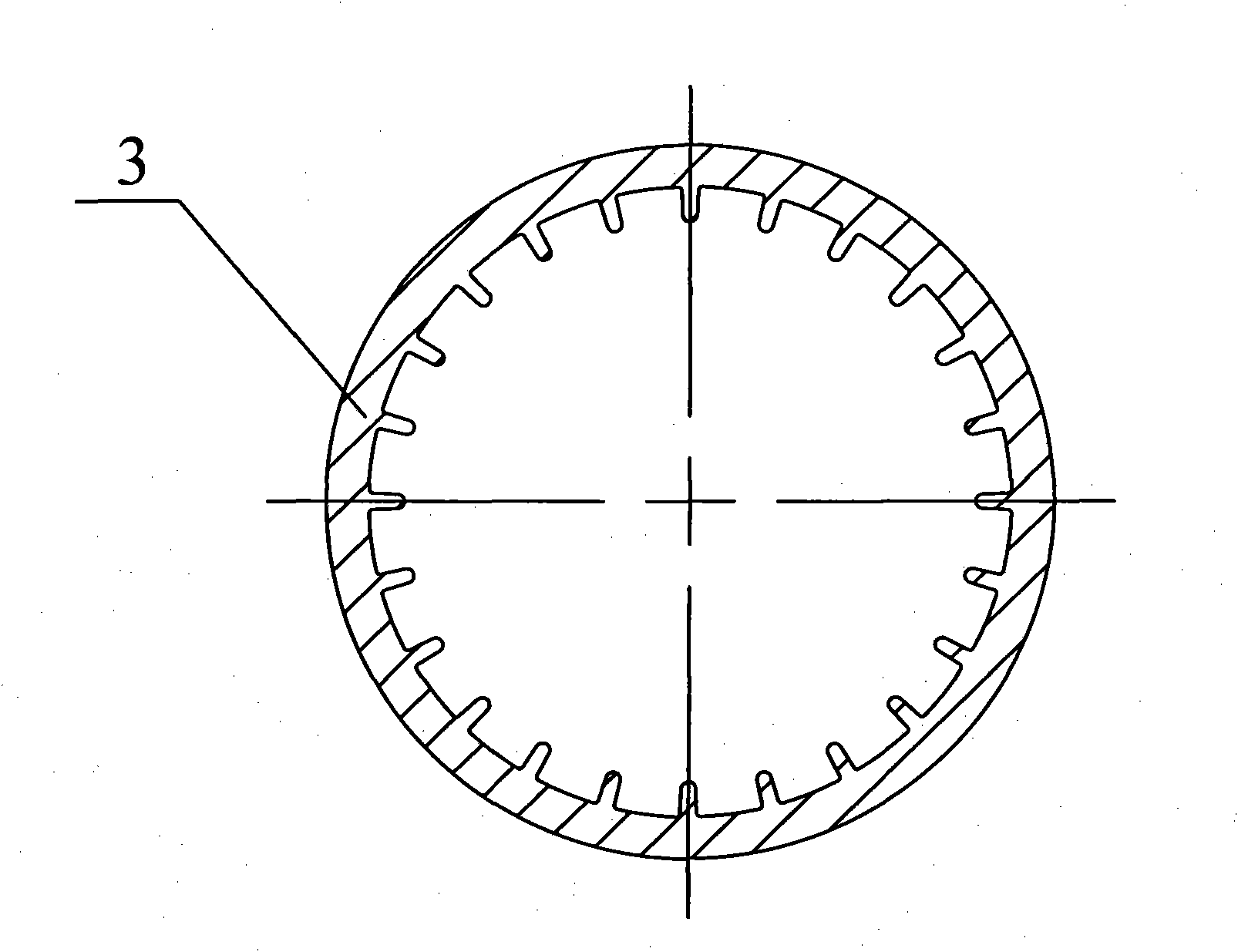

[0037] Such as image 3 As shown, a copper tube 3 with an outer diameter of 6 mm and a length of 1 meter is prepared, and its inner wall is attached with axially extending micro-toothed fins to separate the inner wall of the copper tube into an axial micro-groove structure with capillary structure characteristics. The number of tooth-shaped fins is 24, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com