Dehydrogenation catalyst taking Sn-containing alumina as carrier and preparation method thereof

A technology of alumina carrier and dehydrogenation catalyst, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

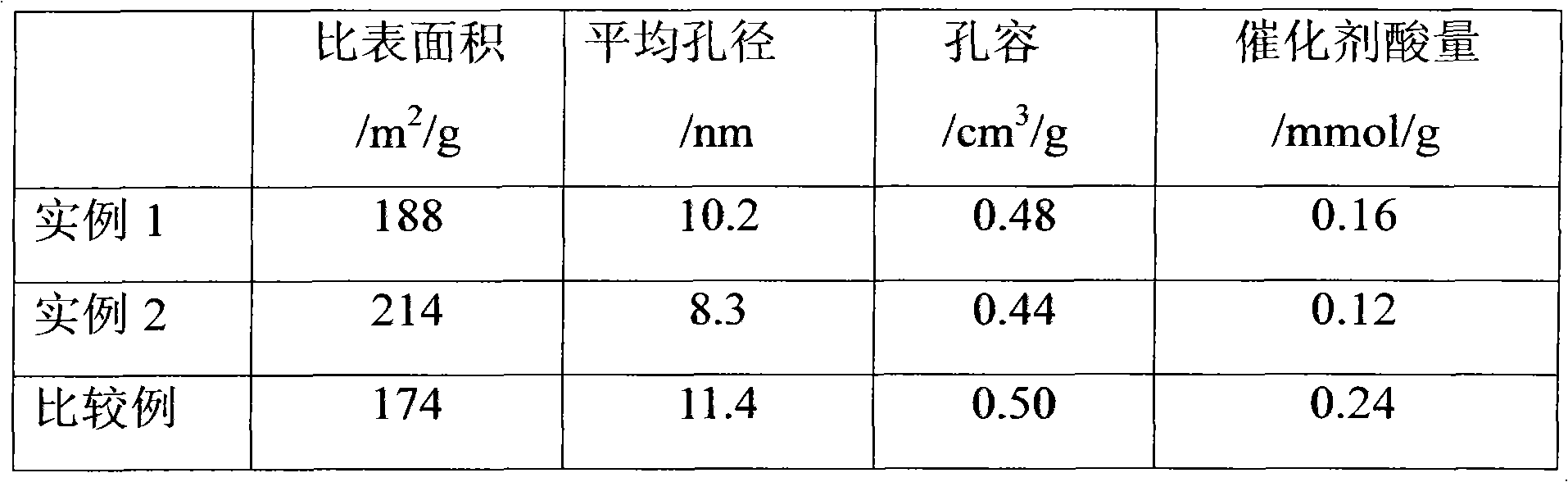

Examples

example 1

[0028] Preparation of Sn-containing alumina support. After mixing 1.13M aluminum trichloride solution and 0.01M tin tetrachloride solution, add ammonia water with a weight concentration of 7%, mix evenly in a neutralization tank at 60-80°C, and control the pH value to 7.0-9.0, After filtering, washing with water, and acidifying, pressurize the oily ammonia column to form balls, age, and roast at 650°C for 4 hours to obtain alumina pellets containing 1.0wt% Sn.

[0029] Put alumina pellets containing 1.0wt% Sn in a tubular reactor, pass through ethylene gas, and pyrolyze at 600°C. After 6 hours, a carrier containing 8% carbon fiber is obtained.

[0030] The modified alumina carrier loaded with carbon nanofibers was impregnated with chloroplatinic acid solution for 12 hours, then evaporated to dryness at 70°C, dried at 120°C for 5 hours, and then calcined at 500°C for 4 hours in an inert atmosphere. Activated in medium for 4h. Then at 70 °C with KNO 3 The catalyst was impregn...

example 2

[0034]Preparation of Sn-containing alumina support. Mix 1.15M aluminum trichloride solution and 0.02M tin tetrachloride solution, add ammonia water with a weight concentration of 10%, mix evenly in a neutralization tank at 60-80°C, control the pH value to 7.0-9.0, filter , washed with water, and acidified, pressurized into spheres in an oily ammonia column, aged, and roasted at 750°C for 4 hours to obtain alumina pellets containing 2.0wt% Sn.

[0035] Alumina pellets containing 2.0wt% Sn were placed in a tubular reactor, fed with ethylene gas, and pyrolyzed at 700°C. After 8 hours, a carrier containing 12% carbon fiber was obtained.

[0036] The modified alumina carrier loaded with carbon nanofibers was co-impregnated with chloroplatinic acid solution for 12 hours, then evaporated to dryness at 70°C, dried at 120°C for 5 hours, and then calcined at 500°C for 4 hours in an inert atmosphere. Activated in nitrogen for 4h. Then at 70°C with KNO 3 The catalyst was impregnated in...

example 3

[0040] Preparation of Sn-containing alumina support. After mixing 1.0M aluminum trichloride solution and 0.01M tin tetrachloride solution, add ammonia water with a weight concentration of 11%, mix evenly in a neutralization tank at 60-80°C, and control the pH value to 7.0-9.0, After filtering, washing with water, and acidifying, pressurize the oily ammonia column to form balls, age, and bake at 700°C for 4 hours to obtain alumina pellets containing 0.5wt% Sn.

[0041] Alumina pellets containing 0.5wt% Sn were placed in a tubular reactor, fed with ethylene gas, and pyrolyzed at 700°C. After 8 hours, a carrier containing 12% carbon fiber was obtained.

[0042] The modified alumina carrier loaded with carbon nanofibers was calcined at 600°C for 3h under an inert atmosphere, co-impregnated with the chloroplatinic acid solution for 6h, rotated to dryness at 70°C, dried at 120°C for 5h, and then Calcined at 500°C for 4 hours in an inert atmosphere, and activated for 4 hours in nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com