Strippable multilayer-structure surface protective film and product thereof

A technology of surface protection film and matrix layer, applied in the direction of heat-activated film/sheet, film/sheet adhesive, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation method of the adhesive composition can adopt any method known in the art. For example, the components may be dry blended followed by melt compounding in a twin-screw extruder. For example, the components can be melt mixed in a twin-screw extruder using a melt temperature of 180-230°C.

[0089] The melt flow index of the blended composition is 0.5-20g / 10min. In order to obtain good processing properties, especially blown film processing, the melt flow index is preferably lower than 15g / 10min (such as 1-14g / 10min, preferably 1.5-13g / 10min), more preferably lower than 10g / 10min ( For example 1.8-10g / 10min, preferably 2-8g / 10min).

[0090] The preparation method of the peelable surface protection film is not particularly limited. The compositions described above can be prepared and applied using a variety of methods and techniques. For example, the adhesive composition may be formed into a film using cast or blown extrusion techniques, and the adhesive f...

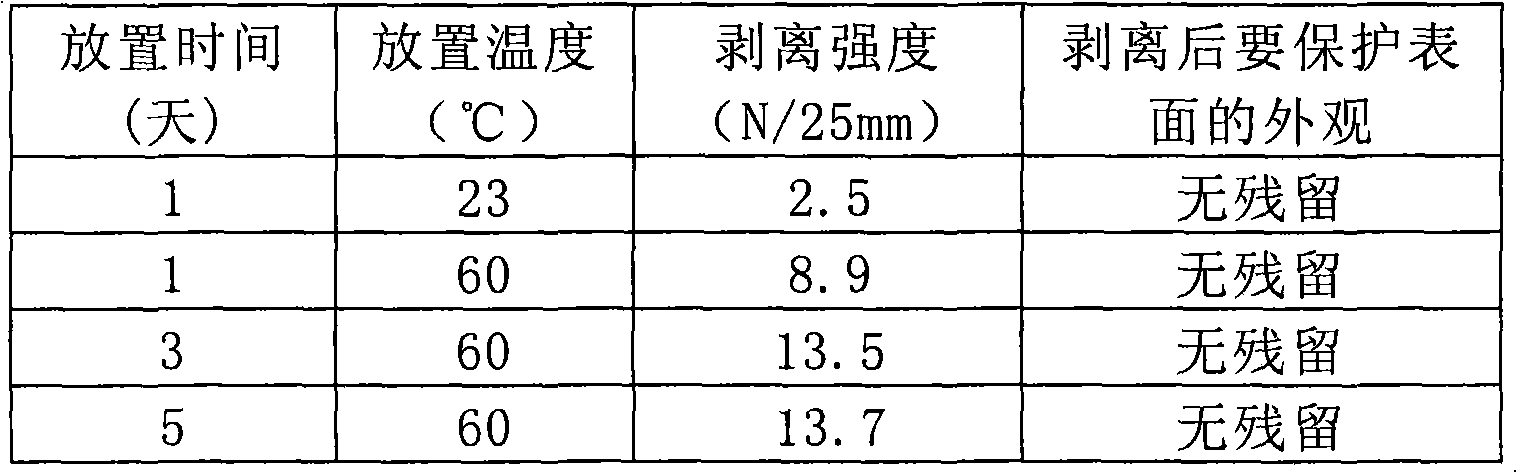

Embodiment 1

[0105] This example illustrates the effect of the addition of LDPE on the aging stability of the final peel strength

[0106] In a 20-mm Brabender twin-screw extruder, 4.11 kg of ethylene-vinyl acetate copolymer (25% by weight vinyl acetate, melt flow rate of 2.0 g / 10 min, melting point of about 77 ° C), 3.23 kg of ethylene-vinyl acetate Vinyl acetate copolymer (28% by weight vinyl acetate, melt flow rate is 6.0g / 10min, about 69 ℃ of fusing points), 2kg maleic anhydride grafted ethylene-vinyl acetate copolymer (28% by weight vinyl acetate , melt flow rate is 1.4g / 10min), 500g hydrogenated hydrocarbon resin tackifier ( 1125, available from Eastman Chemical Company), 10g of antioxidant (anox TM 20N (trade name available from Chemtura) and 3.3 kg of low density polyethylene (density 0.923, melt flow index 2.0 g / 10 min) were melt mixed. The extruder screws are set so that all components are melted / kneaded and properly dispersed. Set the processing zone temperature at 130-190...

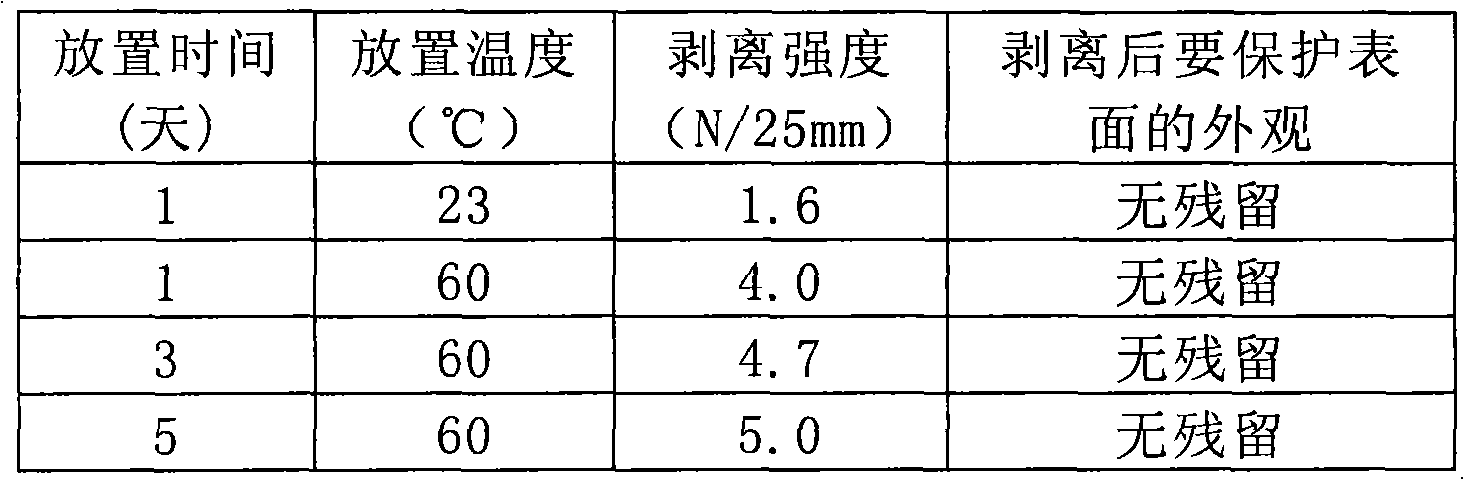

Embodiment 2

[0114] This example illustrates the effect of the addition of LDPE on the aging stability of the final peel strength

[0115] In a 20-mm Brabender twin-screw extruder, 4.11 kg of ethylene-vinyl acetate copolymer (25% by weight vinyl acetate, melt flow rate of 2.0 g / 10 min, melting point of about 77 ° C), 3.23 kg of ethylene-vinyl acetate Vinyl acetate copolymer (28% by weight vinyl acetate, melt flow rate is 6.0g / 10min, about 69 ℃ of fusing points), 2kg maleic anhydride grafted ethylene-vinyl acetate copolymer (28% by weight vinyl acetate , melt flow rate is 1.4g / 10min), 500g hydrogenated hydrocarbon resin tackifier ( 1125, available from Eastman Chemical Company), 10g of antioxidant (anox TM 20N (trade name available from Chemtura) was melt mixed with 1.1 kg of low density polyethylene (density 0.923, melt flow index 2.0 g / 10 min). The extruder screws are set so that all components are melted / kneaded and properly dispersed. Set the processing zone temperature at 130-190...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com