Solar-heat pump combined food air thawing system and thawing method

A technology of solar hot water and solar energy, applied in solar thermal power generation, food preservation, food processing, etc., can solve the problems of high cost, uneven thawing, pollution of frozen products, etc., achieve remarkable energy saving effect, good thawing effect, and simple system Effect

Inactive Publication Date: 2010-11-24

SOUTHEAST UNIV

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Water thawing, because water has better heat transfer performance than air, so water thawing has the characteristics of fast thawing speed and avoids weight loss, but there are problems such as microbial contamination of frozen products and loss of soluble substances in thawing water

Microwave thawing (915MHz or 2450MHz) is under the action of an alternating electric field, using the electrical properties of the substance itself to generate heat to thaw frozen products. The advantages of using microwave thawing are fast speed, high efficiency, less susceptible to microbial contamination, and less loss of nutrients. , its disadvantage is that it is not suitable for complete thawing, and the thawing is uneven

Vacuum thawing is to use the latent heat released by the condensation of water vapor in the vacuum chamber on the surface of frozen food. Its advantages are that the surface of the food is not affected by high-temperature media, and the thawing is fast, and the juice loss after thawing is small, but the disadvantage is that the appearance of the thawed food is not good , and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

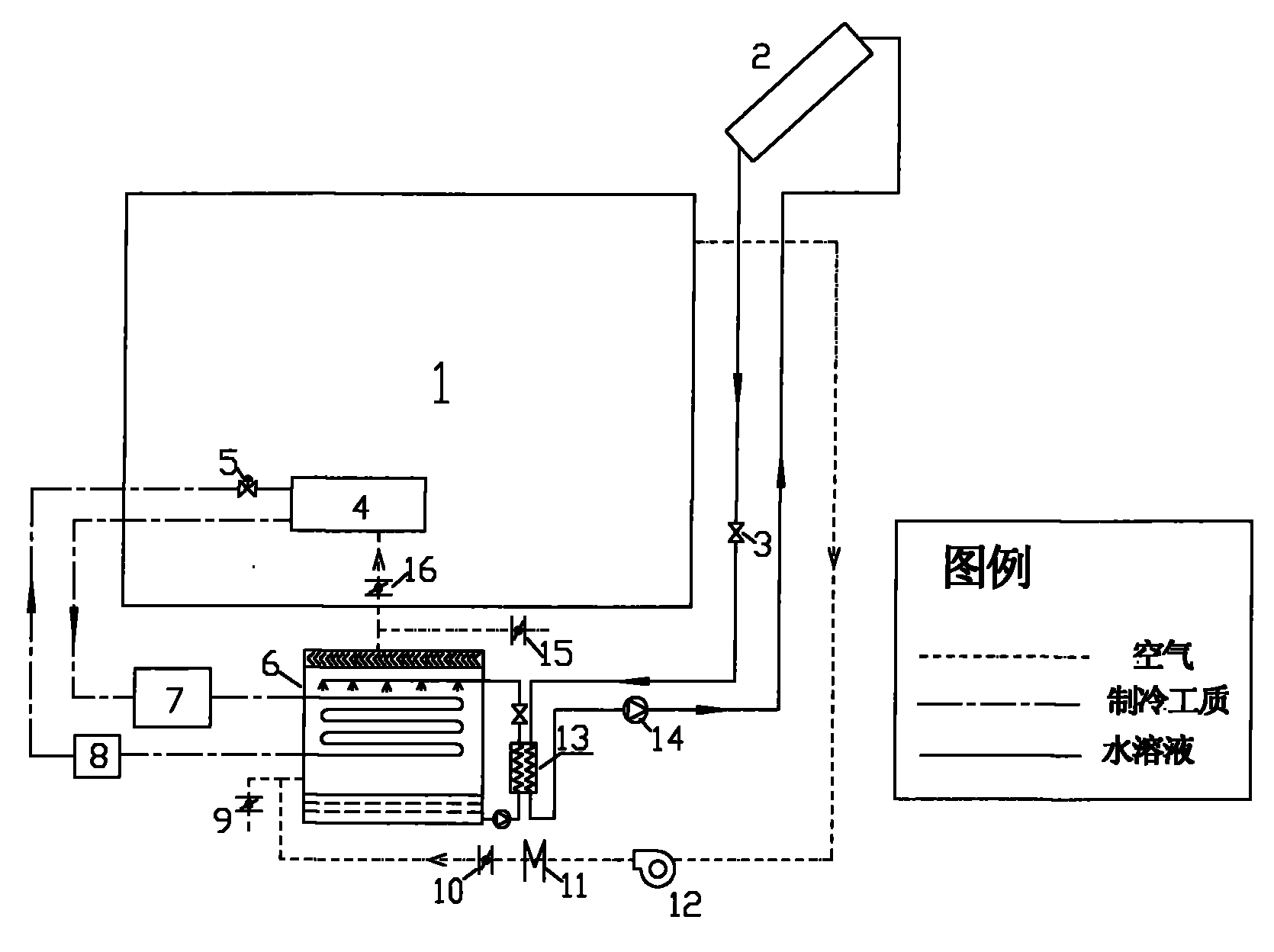

Login to View More Abstract

The invention provides a solar-heat pump combined food air thawing system and a solar-heat pump combined food air thawing method and belongs to the technical field of food air thawing. The system comprises an air circulation subsystem, a solar hot water circulation heat exchange subsystem and a refrigerating medium circulating subsystem. The air circulation subsystem comprises a food thawing chamber (1), a fan (12), an air electric heater (11), an air volume regulating valve (10), an atmospheric condenser (6), an air volume regulating valve (16) and an evaporator (14); the solar hot water circulation heat exchange subsystem comprises a solar heat collector (2), a water flow regulating valve (3), a water-water heat exchanger (13) and a water supply pump (14); and the refrigerating medium circulating subsystem comprises a refrigerating fluid container (8), the atmospheric condenser (6), a refrigerating expansion valve (5), the evaporator (4) and a refrigerating compressor (7). The system has the advantages of quick thawing, high thawing quality, simple process, obvious energy conservation and the like.

Description

A solar energy and heat pump composite food air thawing system and thawing method technical field The invention relates to a solar energy and heat pump composite food air thawing system and a thawing method, belonging to the field of food air thawing. Background technique In recent years, the consumption of frozen food has continued to expand, and the quality requirements for frozen food have also become higher and higher. Frozen food must be thawed before consumption or processing. During the thawing process, the quality of the food should be minimized during the thawing process, so that the quality of the food after thawing is as close as possible to the quality of the food before freezing. In addition, how to ensure the quality of the product? Under these conditions, improving the performance of equipment and reducing processing energy consumption are common concerns of food companies. At present, there are many ways to thaw food, such as water thawing, microwave thaw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L3/365

CPCY02E10/44Y02A40/924Y02P60/85

Inventor 闫俊海张小松

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com