Methods of predicting residual stresses and distortion in quenched aluminum castings

A residual stress, aluminum casting technology, applied in the system field of predicting residual stress and deformation in quenched aluminum castings after solution treatment, can solve problems such as unrealistic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

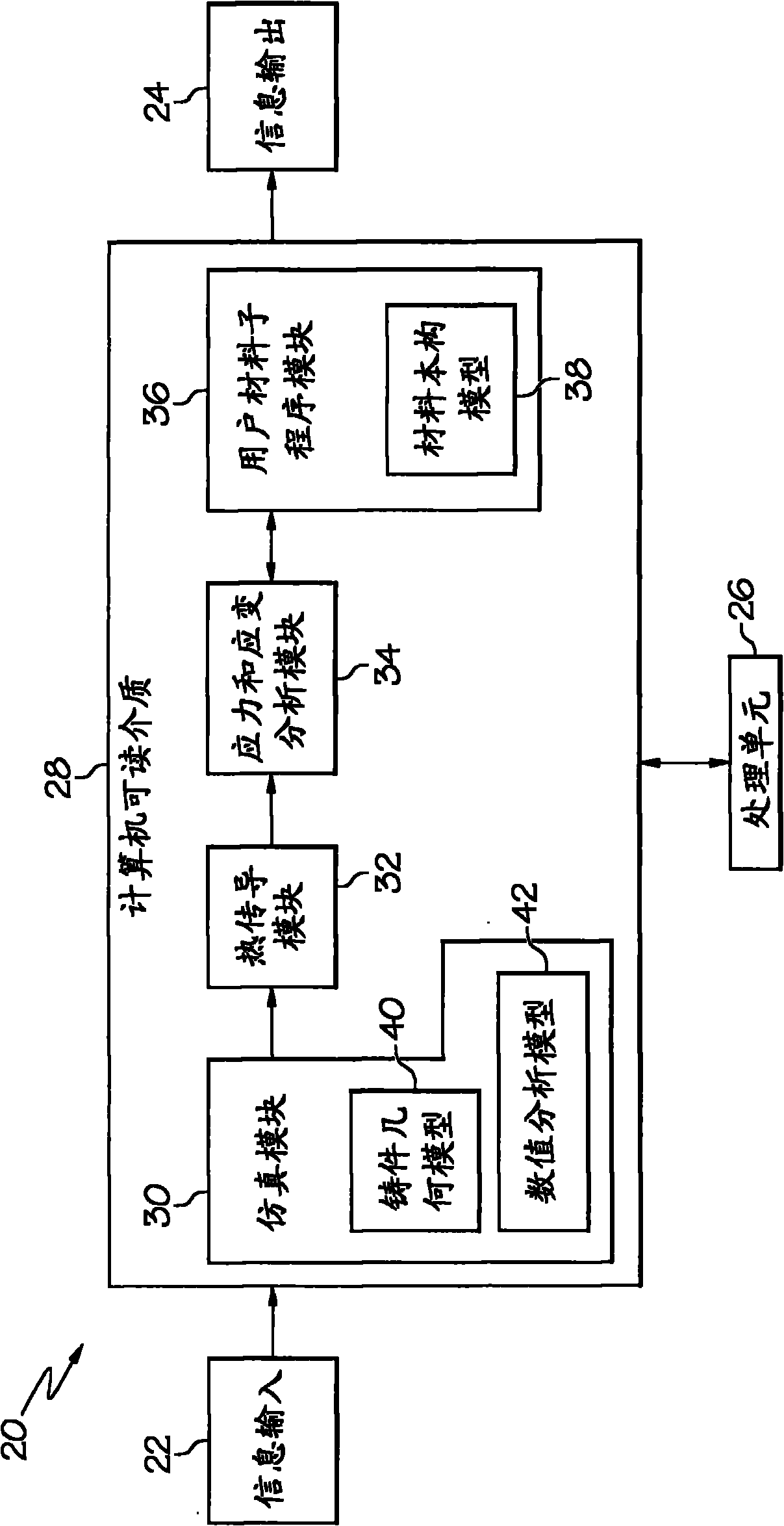

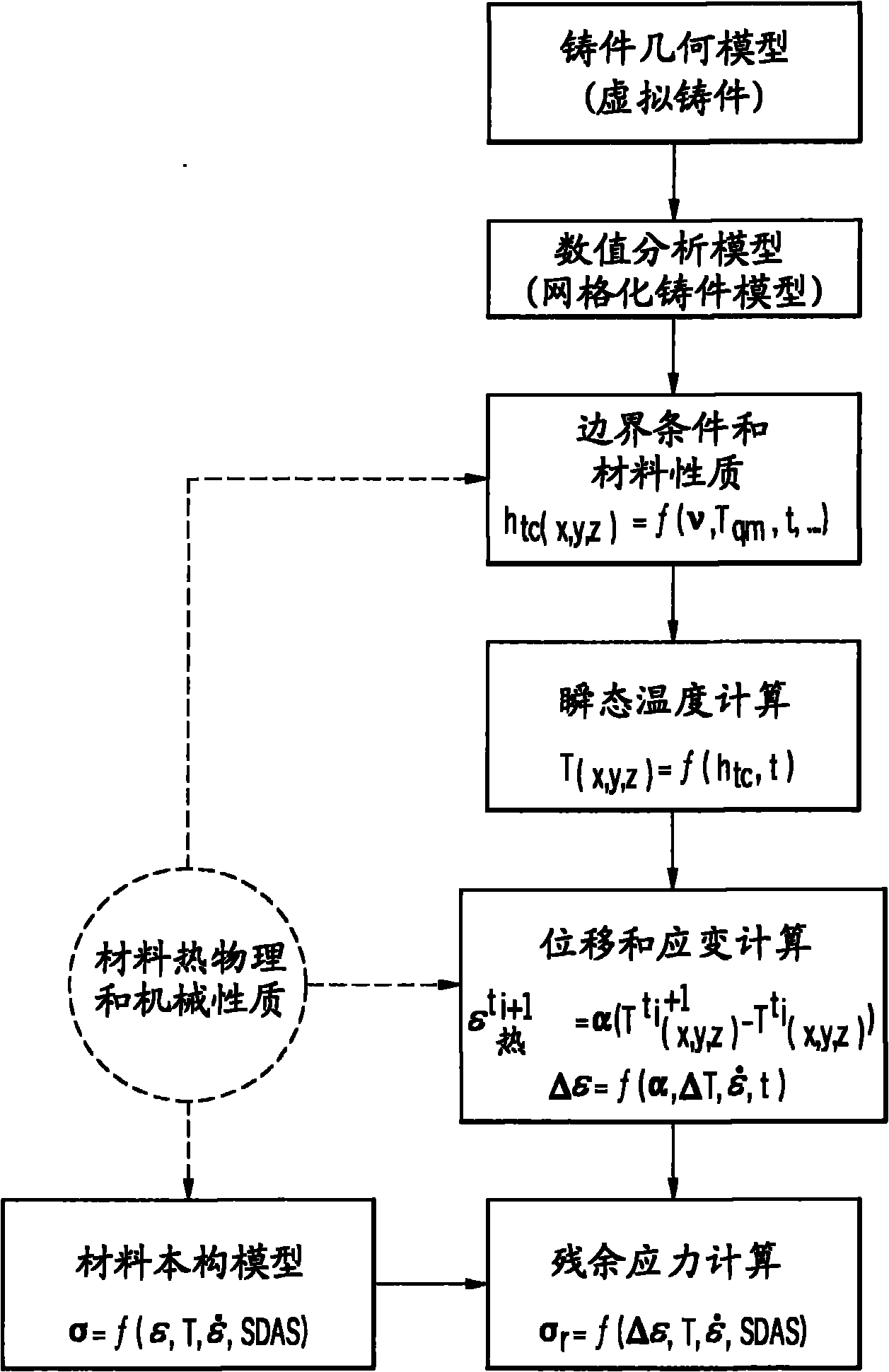

[0155] As described above, the embodiments of the present invention generally relate to systems, methods, and articles of manufacture for predicting residual stress and / or deformation in quenched aluminum castings. In quenching, the residual stress and deformation caused in aluminum castings are generally caused by the difference in cooling rate, temperature and thermal shrinkage rate between the position and position of the aluminum casting geometric structure. According to an embodiment, the strain and stress analysis module predicts at least one of residual stress and deformation in the quenched aluminum casting. Using strain and stress analysis, the residual stress and deformation can be predicted by combining the thermal strain caused by quenching with the non-linear constitutive behavior of the quenched microstructure of the quenched aluminum casting. The thermal strain usually spans the entire section of the aluminum casting during quenching Caused by the non-uniform tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com