Low-noise pollution-free full-automatic concrete anti-abrasion tester

A non-polluting, fully automatic technology, applied in the direction of testing wear resistance, instruments, measuring devices, etc., can solve the problems of dust pollution, poor test environment and conditions, unreachable, etc., to improve the working environment, solve the harsh test environment, Avoid loud noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

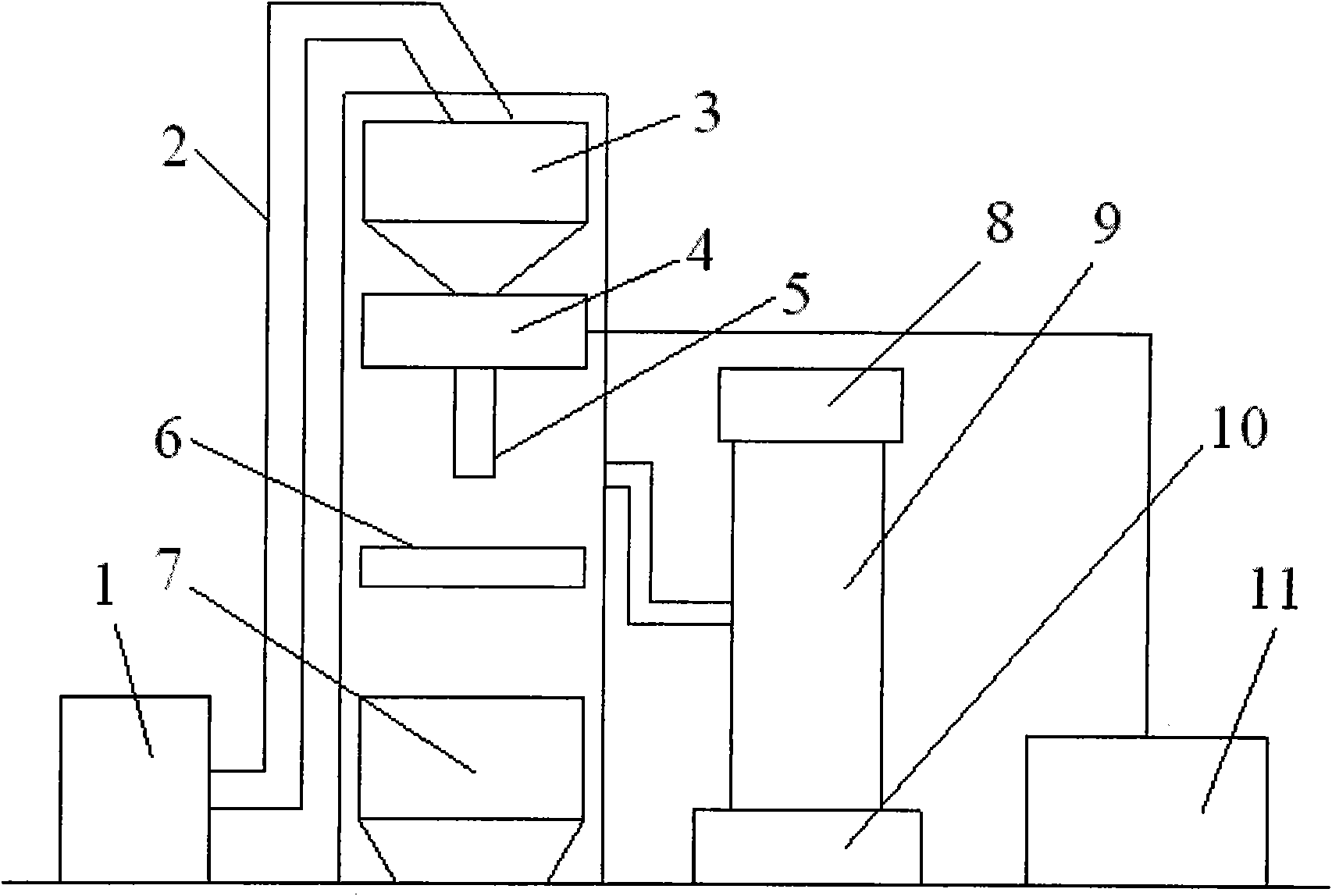

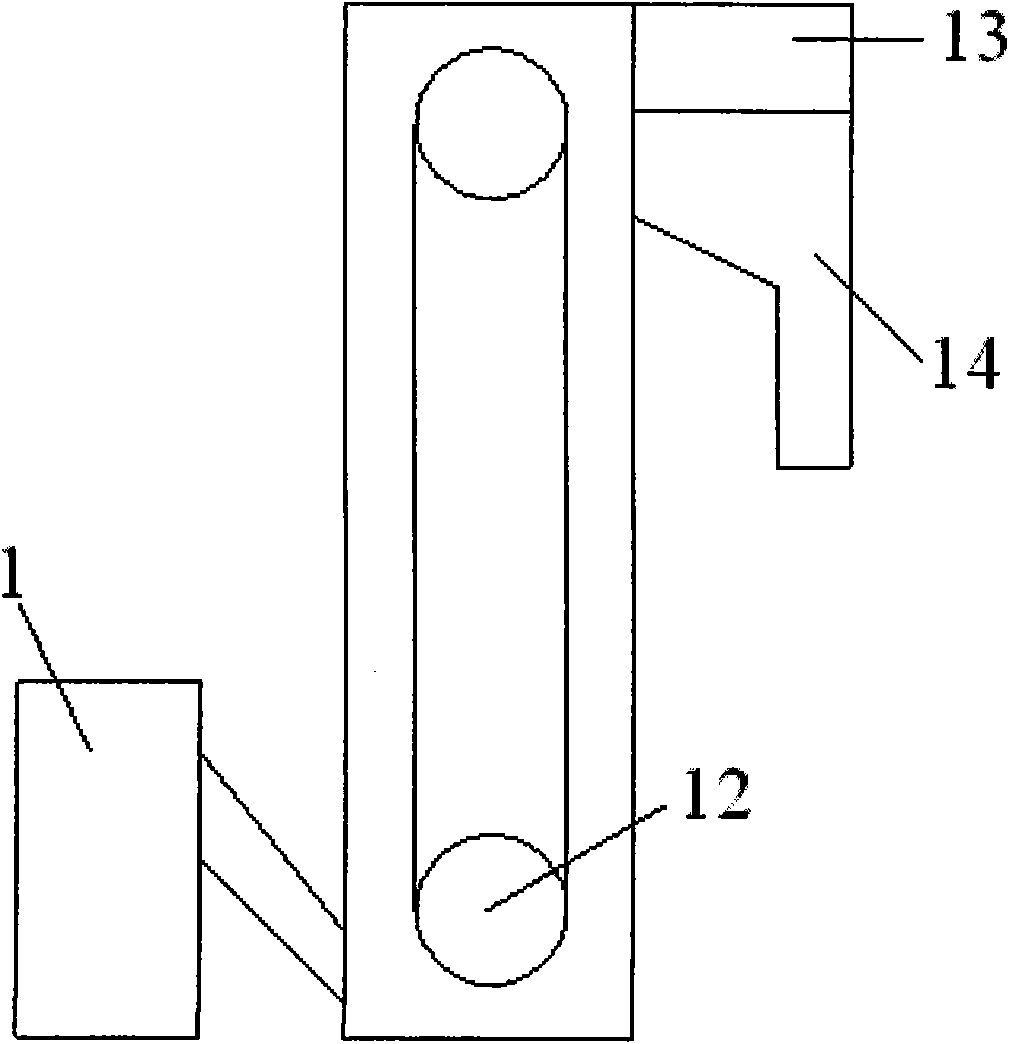

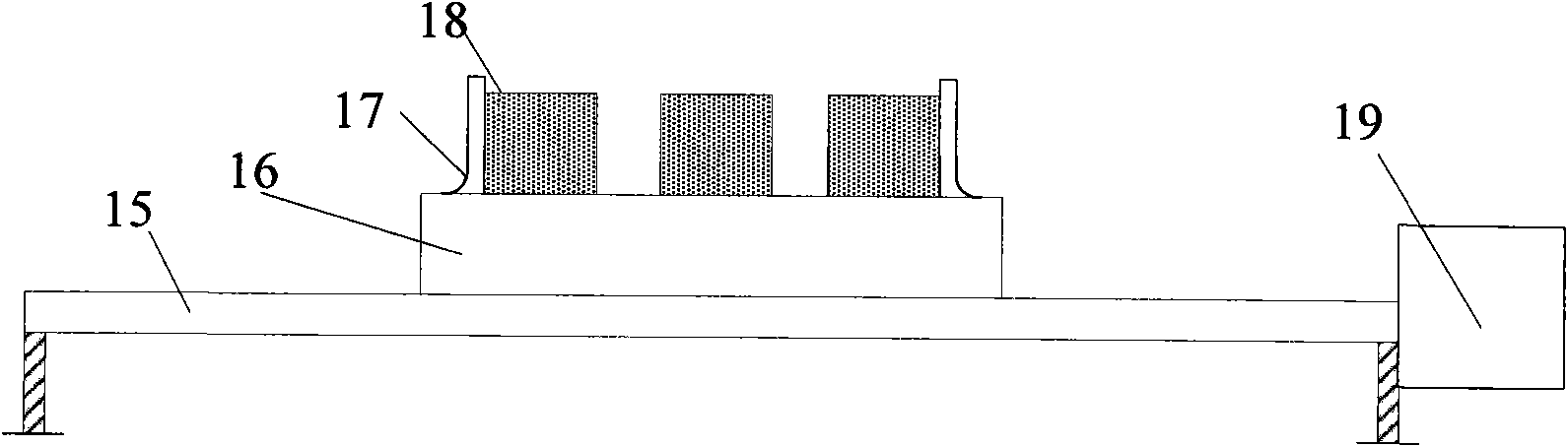

[0025] see figure 1 , 3 , a low-noise and pollution-free fully automatic concrete anti-scour test machine, which includes a closed box, with a storage box 3 inside the box, and a spray gun group 4 at the bottom of the storage box, and the spraying speed of the spray gun group is ≥ 60m / s, and the spray rate can be adjusted. The bottom of the gun group is connected with the spray gun linkage mechanism 5. The spray gun linkage mechanism mixes the air coming in from the air compressor and the abrasive sand coming out of the storage box to produce a jet flow that meets the spray rate required by the test. , a mobile working platform 6 is provided under the spray gun linkage mechanism, and a receiving box 7 is arranged under the mobile working platform. A dust removal system is connected, an air compressor 11 is provided outside the spray gun group, and the mobile working platform includes a moving mechanism 15 controlled by a control motor 19, a test piece bearing platform 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com