Constant torque rubber strip rolling gun tool

A rolling and adhesive strip technology, applied in the field of fixed-torque adhesive strip rolling gun tooling, can solve the problem that the adhesive strip cannot be attached to the body and other problems, so as to reduce the inaccurate lamination position, reduce the workload, and reduce the lamination gap. larger effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

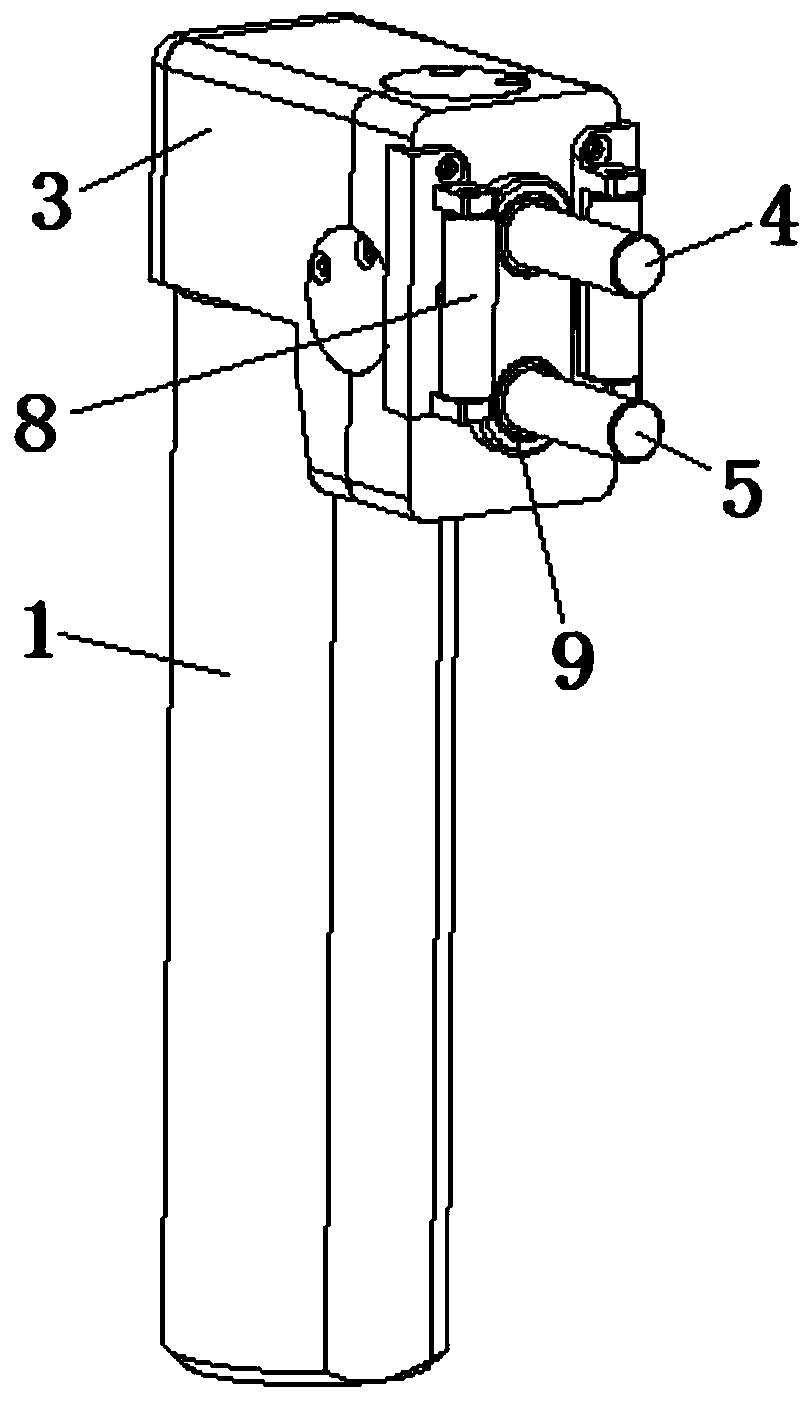

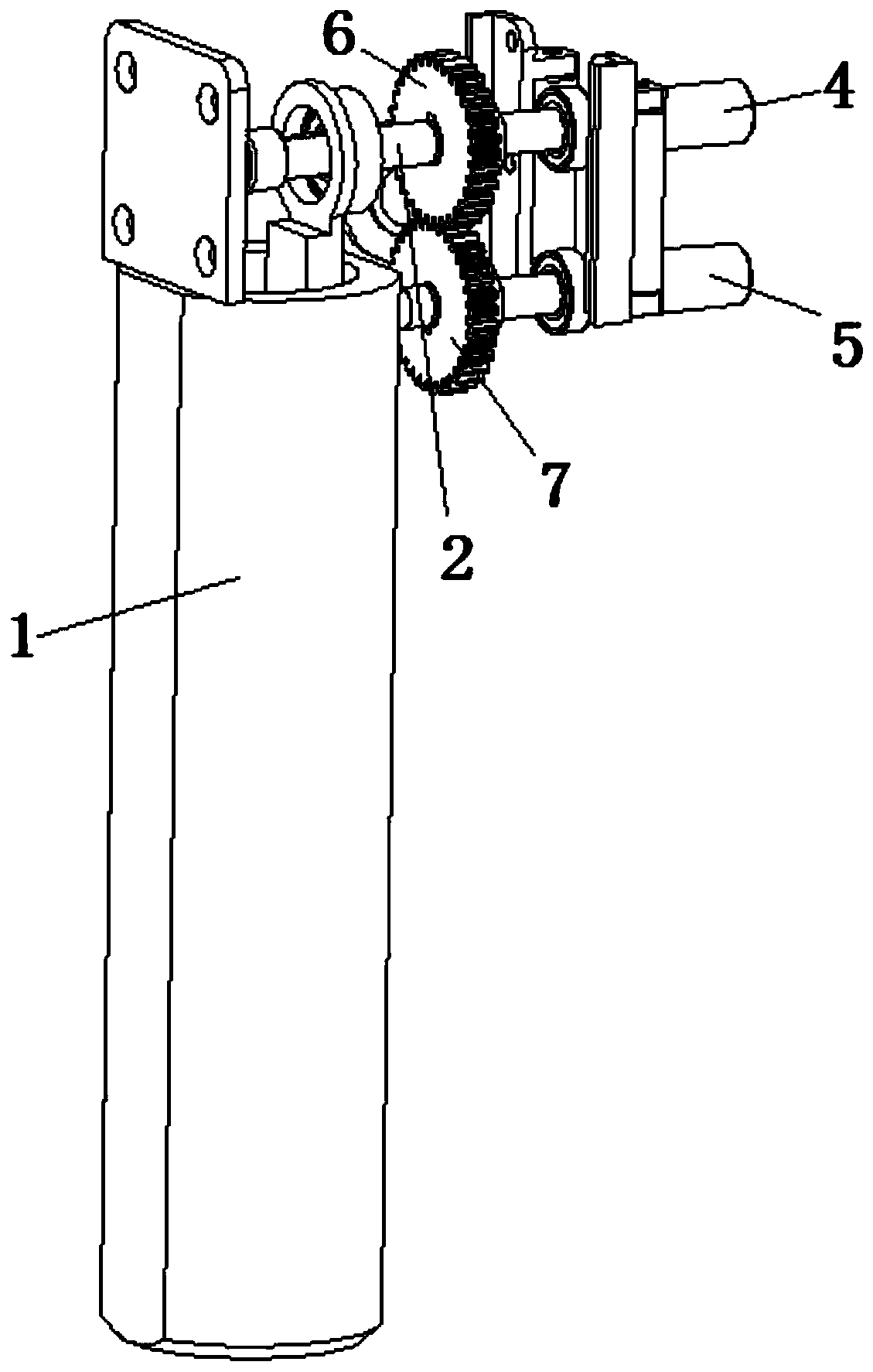

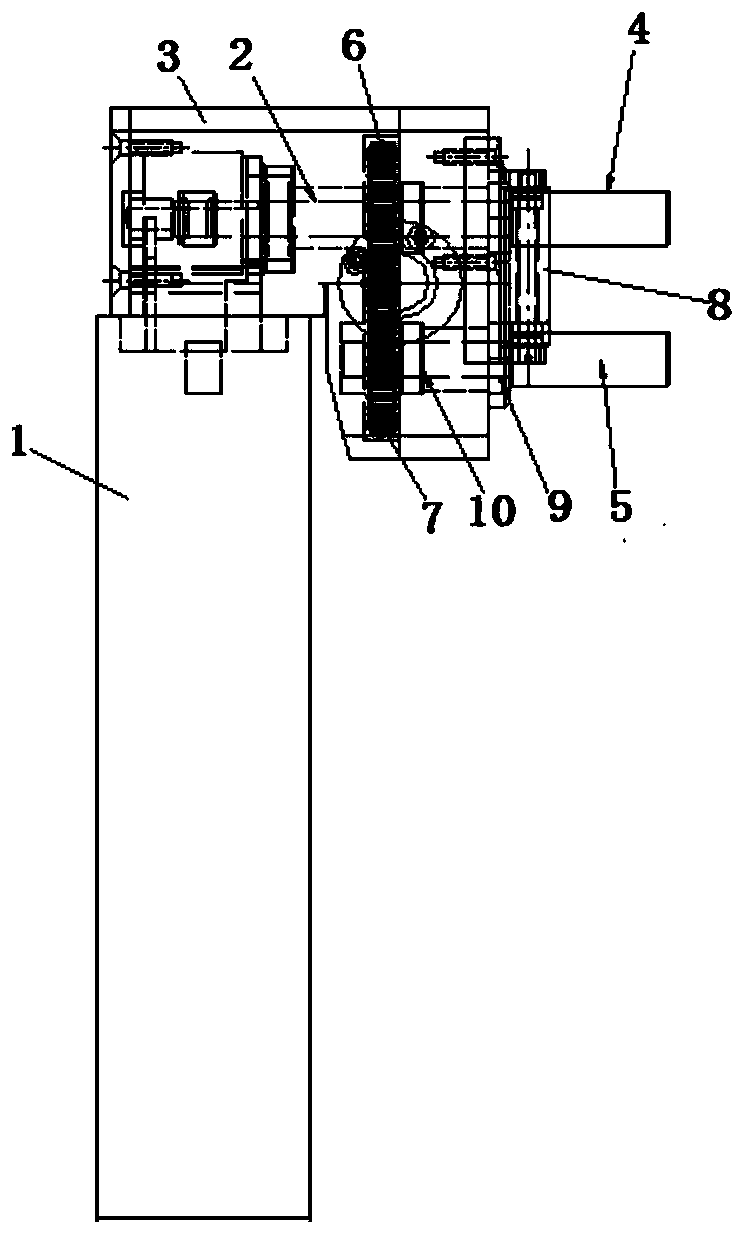

[0016] like Figure 1-Figure 3 As shown, a fixed-moment rubber strip rolling gun tooling includes a rolling gun 1, the output shaft 2 of the rolling gun 1 is connected to a housing 3, and the front side of the housing 3 is rotated and installed with a first transmission shaft 4 and a second transmission shaft. Two transmission shafts 5, the first transmission shaft 4 and the second transmission shaft 5 are axially along the front and rear horizontal directions, the second transmission shaft 5 is located below the first transmission shaft 4, and one end of the first transmission shaft 4 penetrates the housing 3 backwards The output shaft 2 of the rolling gun 1 is fixedly connected to the inside and coaxially, and the other end of the first transmission shaft 4 passes through the front side of the housing 3, and the first gear is coaxially fixed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com