Method for extracting cedar oil and co-producing active carbon from China fir sawdust

A technology for fir chips and fir oil, which is applied in the field of fir chips to extract fir oil and co-producing activated carbon, can solve the problems of non-compliance with low-carbon development, unstable quality, insufficient combustion, etc., shortening activation time, reducing production costs, and reducing raw materials. Consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

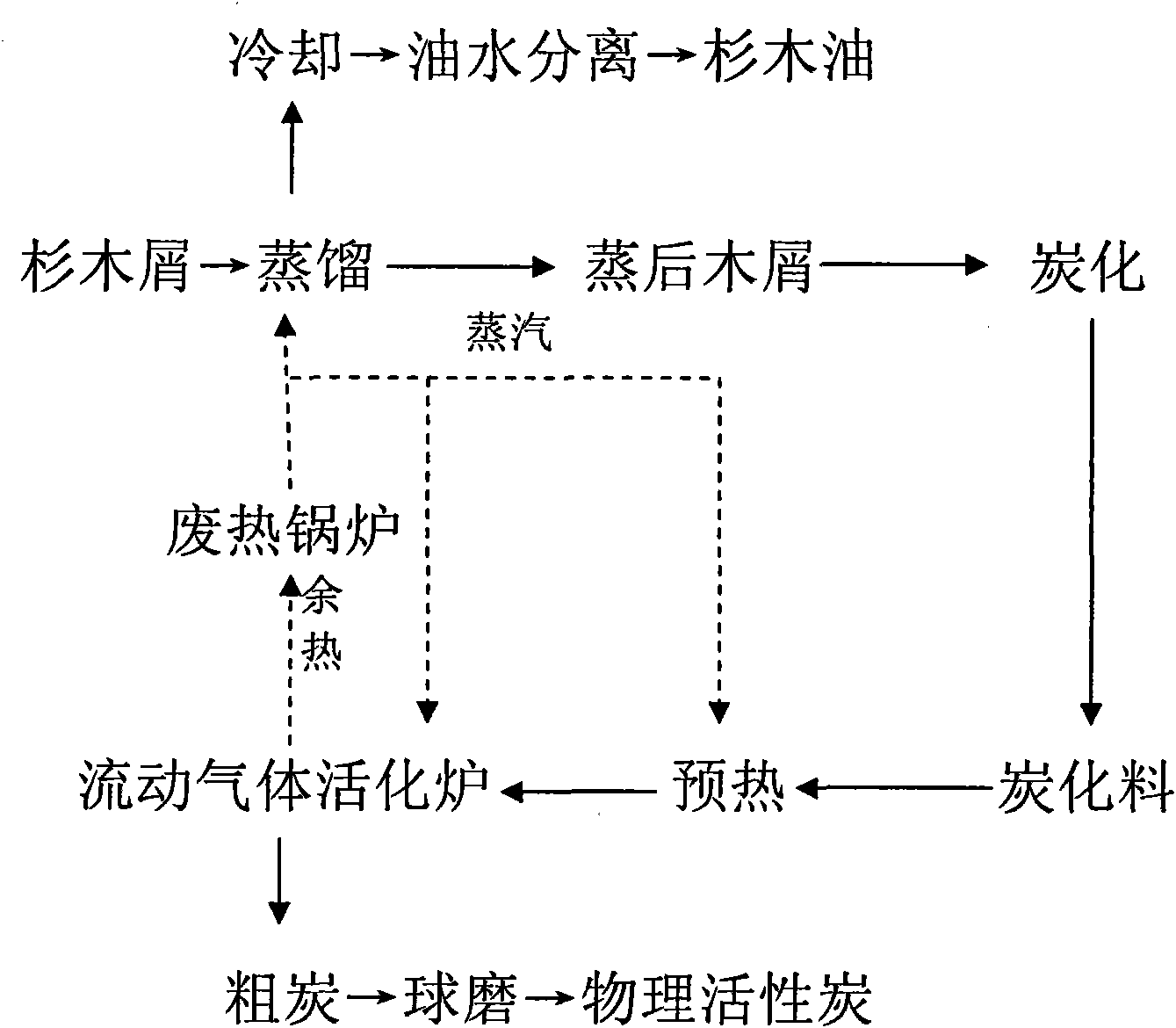

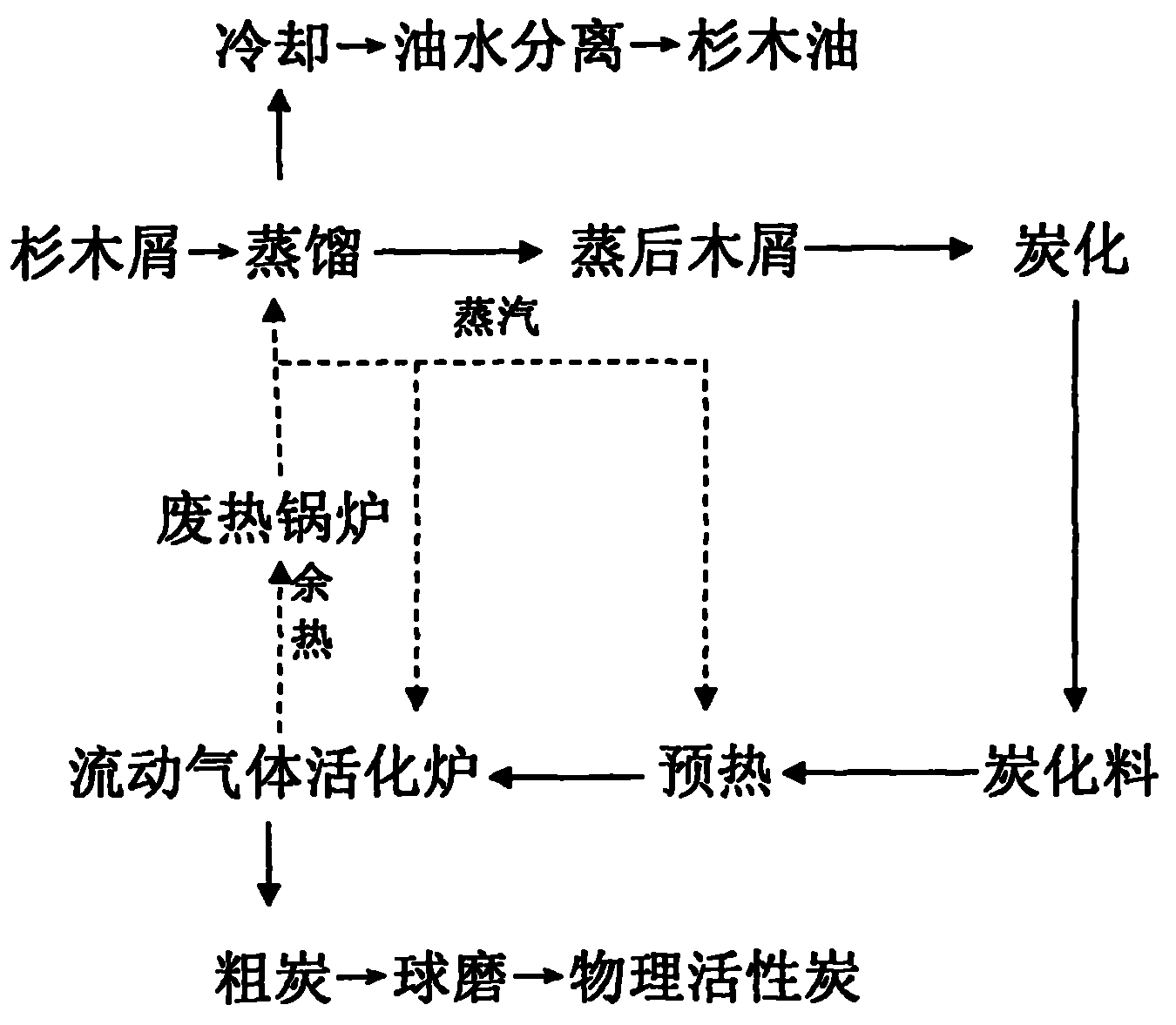

[0015] A method for extracting fir oil co-production activated carbon from Chinese fir chips, comprising the steps of:

[0016] (1) Use waste heat boiler recovery waste heat in the production process of activated carbon to produce steam with a pressure of 3-4Kpa. A part of the steam with a water content of 30% is to distill the fresh Chinese fir chips. The steam temperature is 100°C. The active ingredients enter the cooling process together with the steam to obtain liquid crude water, and the oil and water are separated to obtain fir oil; after the oil is steamed, the fir chips are simmered and carbonized to make a carbonized material with a water content of 10%;

[0017] (2) Use the waste heat boiler to recover the waste heat in the production process of activated carbon, and the other part of the steam with a pressure of 3-4Kpa is used to preheat the carbonized material, so that the temperature of the carbonized material is 80 ° C, and then pushed into the flowing gas activat...

Embodiment 2

[0019] A method for extracting fir oil co-production activated carbon from Chinese fir chips, comprising the steps of:

[0020] (1) Use waste heat boiler to reclaim waste heat in the production process of activated carbon to produce steam with a pressure of 3-4Kpa. A part of the water content is 40% fresh Chinese fir chips to be distilled. The steam temperature is 120°C. The active ingredients enter the cooling process together with the steam to obtain liquid crude water, and the oil and water are separated to obtain fir oil; after the oil is steamed, the fir chips are simmered and carbonized to make a carbonized material with a water content of 12%;

[0021] (2) Using the waste heat boiler to recover the waste heat in the production process of activated carbon, the other part of the steam with a pressure of 3-4Kpa is used to preheat the carbonized material, so that the temperature of the carbonized material is 100°C, and then it is pushed into the flowing gas activation furnac...

Embodiment 3

[0023] A method for extracting fir oil co-production activated carbon from Chinese fir chips, comprising the steps of:

[0024] (1) Use waste heat boiler recovery waste heat in the production process of activated carbon to produce steam with a pressure of 3-4Kpa. A part of the steam with a water content of 35% is distilled with 35% fresh Chinese fir chips. The steam temperature is 110°C. The active ingredients enter the cooling process together with the steam to obtain liquid crude water, and the oil and water are separated to obtain fir oil; after the oil is steamed, the fir chips are simmered and carbonized to make a carbonized material with a water content of 11%;

[0025] (2) Using the waste heat boiler to recover the waste heat in the production process of activated carbon, the other part of the steam with a pressure of 3-4Kpa is used to preheat the carbonized material, so that the temperature of the carbonized material is 90°C, and then it is pushed into the flowing gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com